Forging and pressing device and method special for coal mine hydraulic support cylinder barrel

A technology of coal mine hydraulic and forging equipment, applied in forging/pressing/hammering machinery, forging presses, forging presses, etc., can solve the problems of heavy weight, weak firmness, inconvenient heating, etc., and achieve high production efficiency and low labor intensity , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

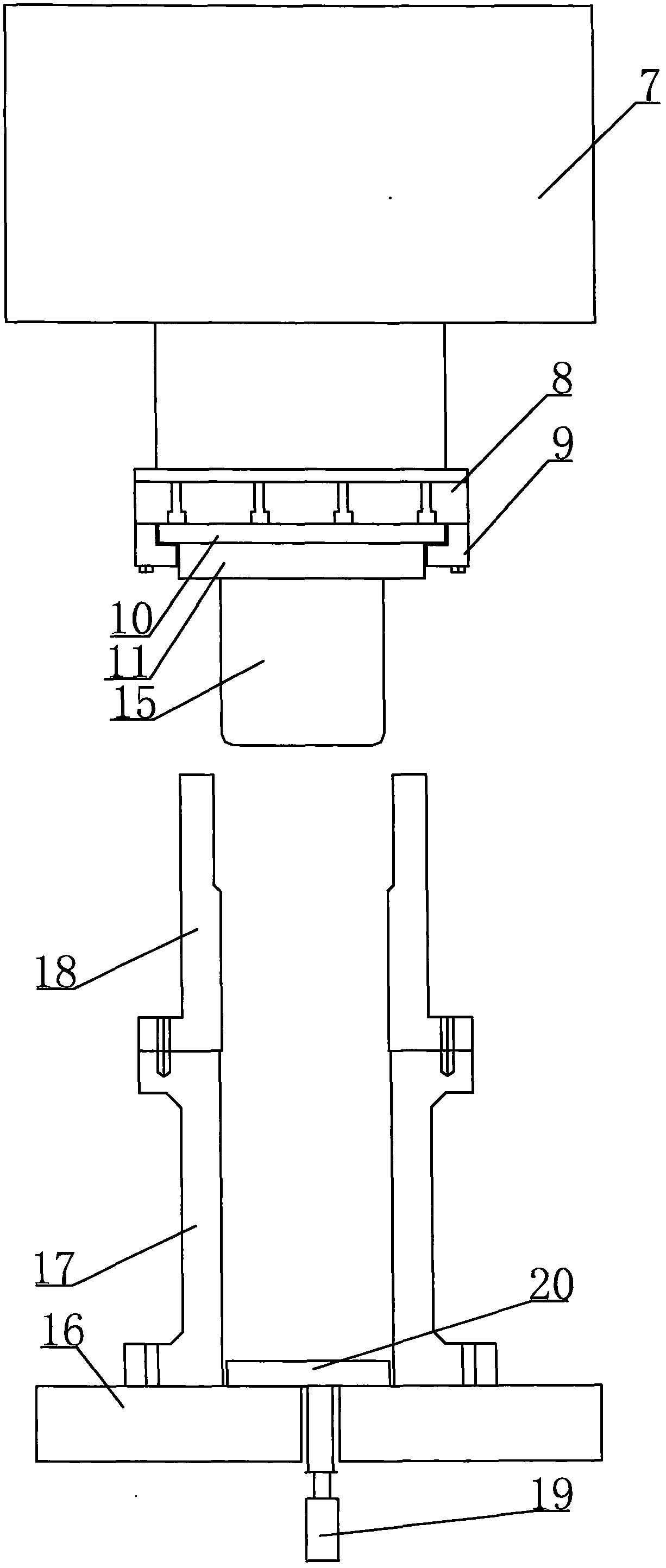

[0044] A forging method of special forging equipment for coal mine hydraulic support cylinder, comprising the following steps:

[0045] Step 1: Prepare materials: cut seamless steel pipes with a length of 500mm, a diameter of Φ350mm, and a wall thickness of 30mm. The material of the seamless steel pipe is: 30CrMnSi;

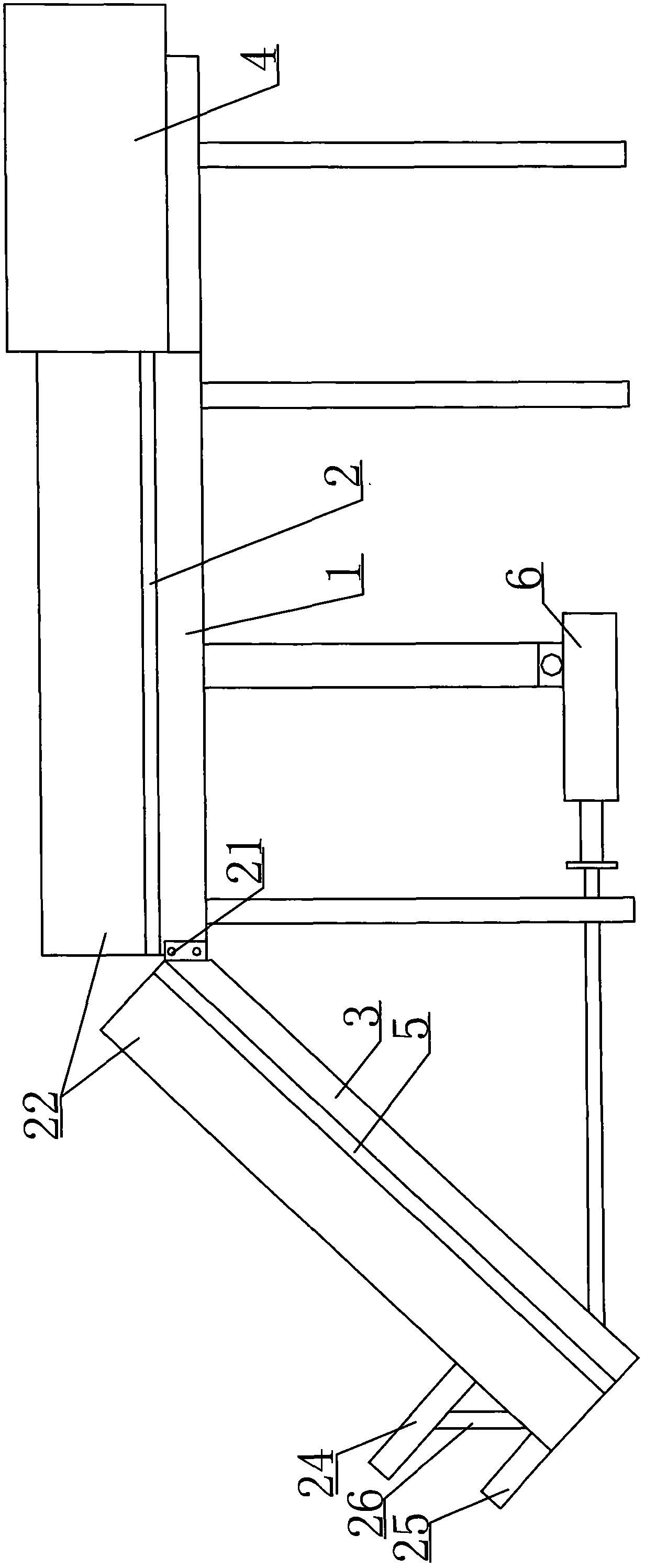

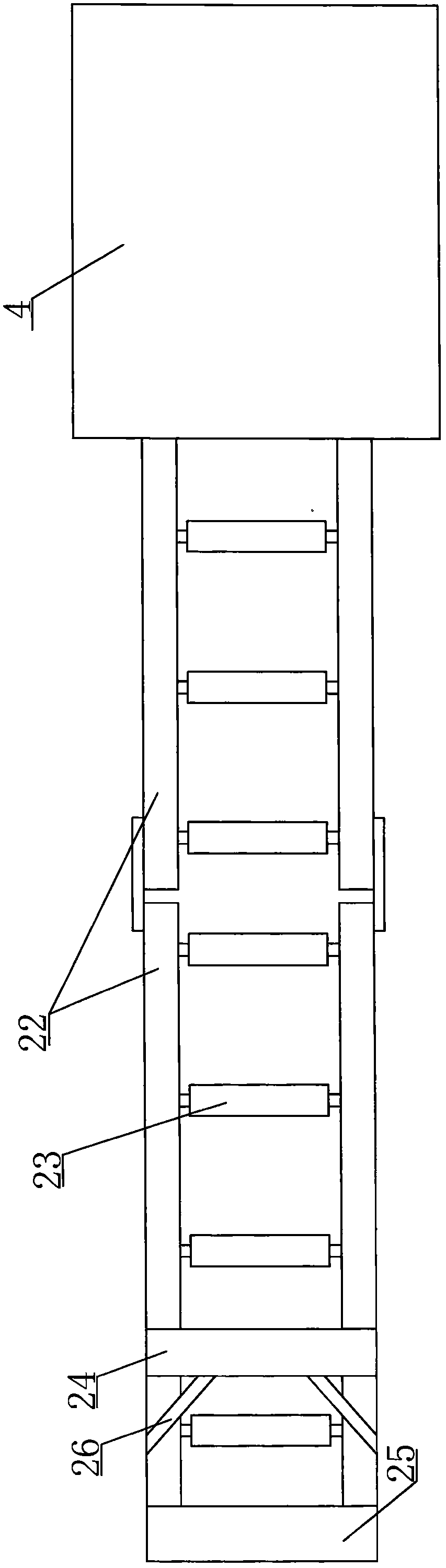

[0046] Step 2: Heating: horizontally place the seamless steel pipe described in step 1 on the fixed track 2 by hoisting equipment, and the end of the seamless steel pipe to be heated is close to the side of the intermediate frequency heating furnace 4;

[0047] Step 3: Manually push the end of the seamless steel pipe to be heated into the intermediate frequency heating furnace 4 for heating to 1000-1100°C;

[0048] Step 4: Manually push and pull the heated seamless steel pipe to the top of the fixed support 1, start the hydraulic cylinder 6, and recover the piston rod end of the hydraulic cylinder 6, and the movable support 3 tilts slowly, and the heated seamless...

Embodiment 2

[0055] A forging method of special forging equipment for coal mine hydraulic support cylinder, comprising the following steps:

[0056] Step 1: Prepare materials: cut seamless steel pipes with a length of 2500mm, a diameter of Φ475mm, and a wall thickness of 65mm. The material of the seamless steel pipe is: 35CrMnSi;

[0057] Step 2: Heating: horizontally place the seamless steel pipe described in step 1 on the fixed track 2 by hoisting equipment, and the end of the seamless steel pipe to be heated is close to the side of the intermediate frequency heating furnace 4;

[0058] Step 3: Manually push the end of the seamless steel pipe to be heated into the intermediate frequency heating furnace 4 for heating to 1000-1100°C;

[0059] Step 4: Manually push and pull the heated seamless steel pipe to the top of the fixed support 1, start the hydraulic cylinder 6, and recover the piston rod end of the hydraulic cylinder 6, and the movable support 3 tilts slowly, and the heated seamles...

Embodiment 3

[0067] A forging method of special forging equipment for coal mine hydraulic support cylinder, comprising the following steps:

[0068] Step 1: Prepare materials: cut seamless steel pipes with a length of 1500mm, a diameter of Φ400mm, and a wall thickness of 45mm. The material of the seamless steel pipe is: 30CrMnSi;

[0069] Step 2: Heating: horizontally place the seamless steel pipe described in step 1 on the fixed track 2 by hoisting equipment, and the end of the seamless steel pipe to be heated is close to the side of the intermediate frequency heating furnace 4;

[0070] Step 3: Manually push the end of the seamless steel pipe to be heated into the intermediate frequency heating furnace 4 for heating to 1000-1100°C;

[0071] Step 4: Manually push and pull the heated seamless steel pipe to the top of the fixed support 1, start the hydraulic cylinder 6, and recover the piston rod end of the hydraulic cylinder 6, and the movable support 3 tilts slowly, and the heated seamles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com