Fixture for steel rail forging, forging device, heat treatment system and heat treatment process

A heat treatment system and rail technology, applied in forging/pressing/hammer devices, heat treatment furnaces, heat treatment equipment, etc., can solve the problems of increased energy consumption, inconvenient quality management, short service life of rails, etc., and achieve the reduction of plant length, The effect of shortening the processing steps and reducing the processing production area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

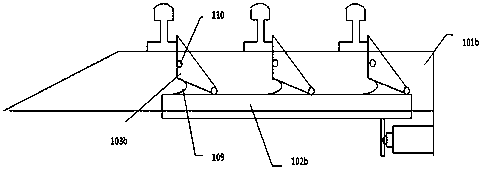

Embodiment 1

[0044] see Figure 1-2 , the present embodiment provides a claw for rail forging, the clamp includes several transverse guide rails arranged side by side, the transverse movement platform is arranged on the transverse movement platform, and several longitudinal Guide rail, the longitudinal movement platform is provided on the longitudinal movement platform, and several claws are evenly spaced and distributed in a straight line on the longitudinal movement platform; the claws include a rotating disk and a rotating disk base, and the rotating disk base can be lifted by The device is fixed on the longitudinal movement platform. There is a rectangular slot on the rotating disk. Small holes are arranged symmetrically and oppositely on the lower part of the inner wall on both sides of the slot. The first telescopic cylinder is arranged in the small hole, and the first telescopic cylinder stretches and retracts. The end of the arm is provided with a clamping plate; the periphery of t...

Embodiment 2

[0051] The present embodiment provides a kind of rail forging device that adopts above-mentioned fixture, please refer to Figure 5 The right half, the device also includes forging equipment and intermediate frequency heating furnace, the forging equipment and intermediate frequency heating furnace are distributed side by side on the side of the end of the longitudinal movement platform of the fixture; The center of the furnace mouth of the furnace is at the same height and in the same vertical plane.

[0052] The side of the forging equipment is provided with an infrared range finder, and the infrared range finder is on the same straight line as the center of the forging die mouth and the center of the intermediate frequency heating furnace mouth; the infrared range finder sends signals to the control system, and the The forging equipment and intermediate frequency heating furnace are all controlled by the control system.

[0053] In this embodiment, by adopting the fixture fo...

Embodiment 3

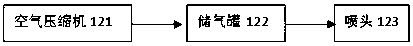

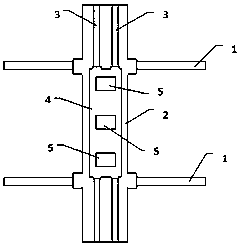

[0056] This embodiment provides a rail heat treatment system using the above-mentioned forging device, the heat treatment system also includes a quenching device, the quenching device is located beside the forging device, the quenching device includes a conveying platform, and the end of the conveying platform is provided with Normalizing furnace, there is also air cooling equipment between the conveying platform and the normalizing furnace, please refer to Figure 12 , the air-cooled equipment includes an air compressor, an air storage tank and a shower head, the air compressor pumps air into the air storage tank, and the air storage tank provides high-pressure airflow to the shower head; the shower head is a chamber structure, including a top plate and a On the side plates on both sides of the top plate, spray holes are evenly distributed inside the side plates and inside the top plate, and flame-retardant cotton slivers are arranged symmetrically and oppositely on the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com