An Abrasive Jet Adaptive Dressing Method for Consolidated Abrasive Polishing Pads

A technology of abrasive jet and fixed abrasive, which is applied in grinding/polishing equipment, parts of grinding machine tools, abrasive surface adjustment devices, etc., can solve the problems of poor technical stability and low efficiency, achieve good dressing effect and improve dressing effective, efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

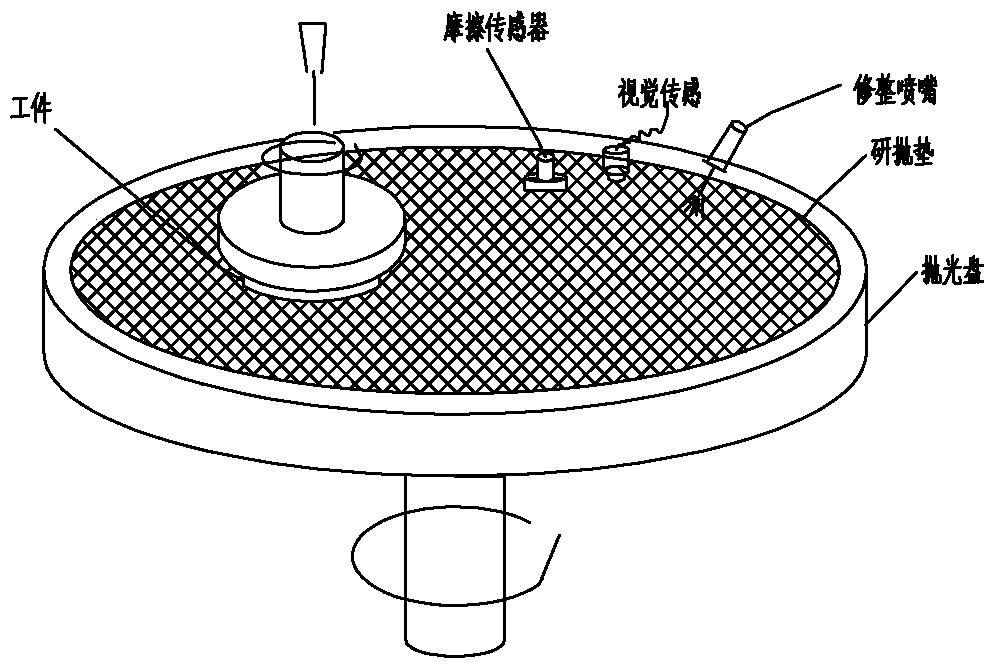

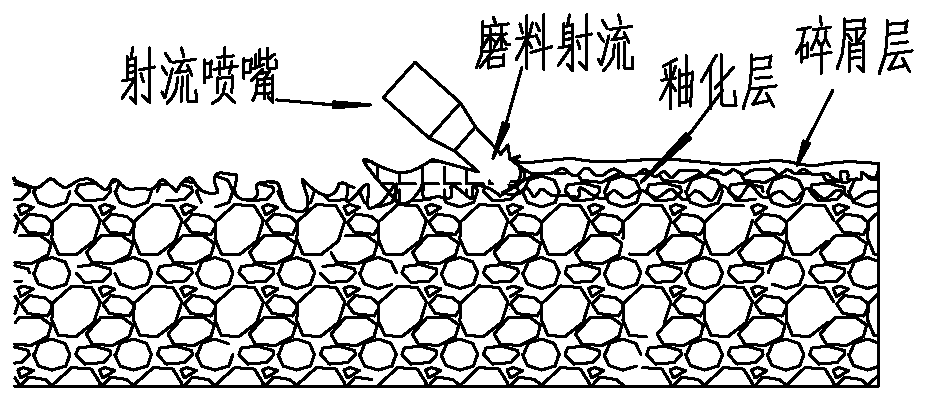

[0028] Such as Figure 1-3 shown.

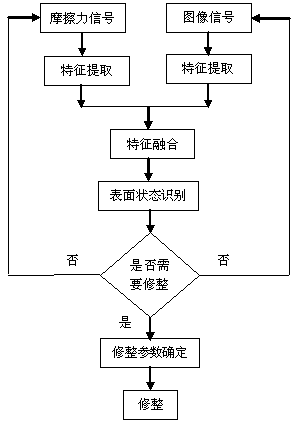

[0029] A method for adaptive dressing of abrasive jets for fixed abrasive polishing pads, the process of which is as follows image 3 As shown, the specific steps are as follows:

[0030] First of all, abrasive jet technology and adaptive parameter setting technology are used as polishing pad dressing methods, such as figure 1 shown;

[0031] Secondly, the characteristics of the surface state of the polishing pad at different stages (including the initial stage, the middle stage, and the end stage) are obtained through image feature recognition; image features include color features, image texture features, shape features, and feature point sizes, etc. The characteristics of the surface state of the throwing pad at different processing stages, such as sharp state, passivation state, etc.;

[0032] Third, obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com