Preparation method of superfine lignin

A technology for lignin and enzymatic hydrolysis of lignin is applied in the field of preparation of ultrafine lignin, which can solve the problems of high cost and low production efficiency, and achieve the effects of improving performance, improving production efficiency and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step (1): 120-mesh lignin and 325-mesh grinding aid aluminum hydroxide are mixed and stirred evenly in a weight ratio of 30:5;

[0032] Step (2): The mixture obtained in step (1) and 0.8MPa compressed air are simultaneously injected into the jet mill to obtain pulverized materials;

[0033] Step (3): Putting the pulverized material obtained in step (2) into a classifier or a classifying chamber for classifying, the classifying speed is 8000r / min, and the classified particles are obtained;

[0034] Step (4): For the classified particles obtained in step (3), return the particles with a particle size of <4000 mesh to the airflow mill for re-grinding, and discharge the particles with a particle size of ≥4000 mesh from the discharge port, which is the ultrafine Lignin.

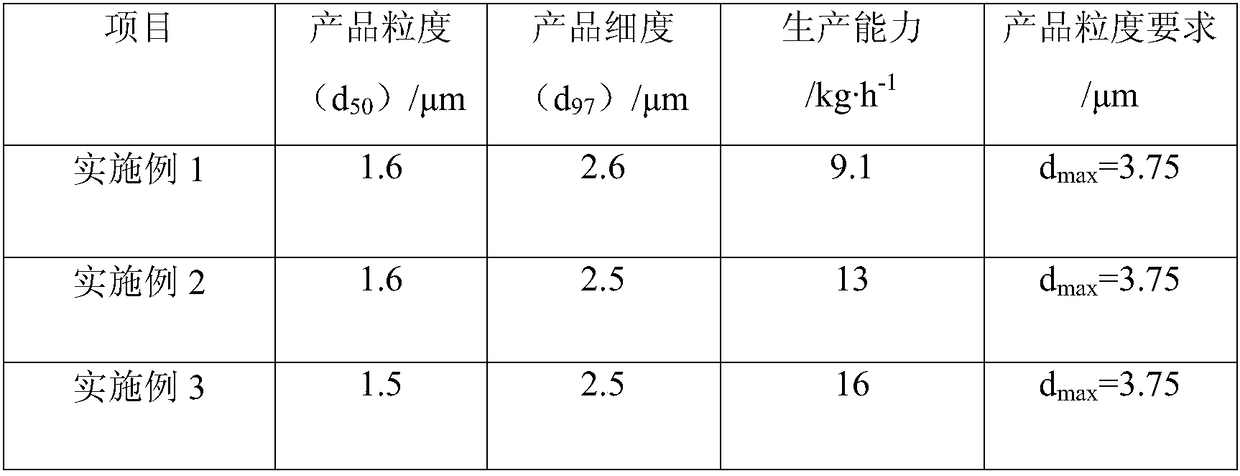

[0035] Various parameters for preparing ultrafine lignin are shown in Table 1.

Embodiment 2

[0037] Step (1): 120-mesh lignin and 325-mesh grinding aid aluminum hydroxide are mixed and stirred evenly in a weight ratio of 20:5;

[0038] Step (2): The mixture obtained in step (1) and 0.8MPa compressed air are simultaneously injected into the jet mill to obtain pulverized materials;

[0039] Step (3): Putting the pulverized material obtained in step (2) into a classifier or a classifying chamber for classifying, the classifying speed is 8000r / min, and the classified particles are obtained;

[0040] Step (4): For the classified particles obtained in step (3), return the particles with a particle size of <4000 mesh to the airflow mill for re-grinding, and discharge the particles with a particle size of ≥4000 mesh from the discharge port, which is the ultrafine Lignin.

[0041] Various parameters for preparing ultrafine lignin are shown in Table 1.

Embodiment 3

[0043] Step (1): 120-mesh lignin and 325-mesh grinding aid aluminum hydroxide are mixed and stirred evenly in a weight ratio of 10:5;

[0044] Step (2): The mixture obtained in step (1) and 0.8MPa compressed air are simultaneously injected into the jet mill to obtain pulverized materials;

[0045] Step (3): Putting the pulverized material obtained in step (2) into a classifier or a classifying chamber for classifying, the classifying speed is 8000r / min, and the classified particles are obtained;

[0046] Step (4): For the classified particles obtained in step (3), return the particles with a particle size of <4000 mesh to the airflow mill for re-grinding, and discharge the particles with a particle size of ≥4000 mesh from the discharge port, which is the ultrafine Lignin.

[0047] Various parameters for preparing ultrafine lignin are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com