Precious metal recycling equipment

A precious metal recovery and equipment technology, applied in the direction of improving process efficiency, etc., can solve the problems of incomplete dissolution and waste of dissolution reaction devices, and achieve the effects of simple structure, reduced production costs, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

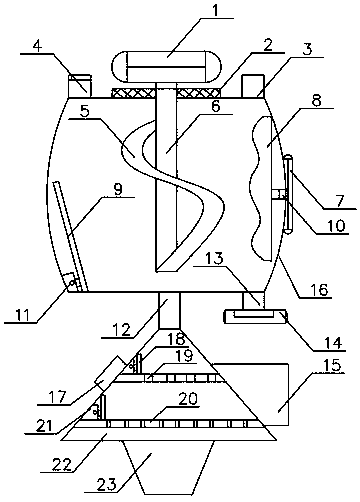

[0019] Such as figure 1 As shown, the precious metal recovery equipment of the present invention includes a motor 1, an adsorption layer 2, a liquid inlet 3, a material inlet 4, a spiral blade 5, a rotating shaft 6, a hydraulic pump 7, a push plate 8, and an upper scraper 9. Hydraulic rod 10, upper pusher 11, passage 12, ventilation pipe 13, air pump 14, slag discharge port 15, dissolving chamber 16, visual window 17, lower scraper 18, primary filter 19, secondary filter 20. Lower pusher 21, filter cavity 22, discharge port 23, the dissolving cavity 16 is provided with a feed port 4 and a liquid inlet 3, the motor 1 is connected to the spiral blade 5 through a rotating shaft 6, and an adsorption layer is provided on the upper end of the dissolving chamber 16. 2. An upper pusher 11 is provided at the bottom of the dissolving chamber 16, which is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com