A kind of graphite oxide corrosion inhibitor and its preparation and application

A technology of corrosion inhibitor and graphene, applied in the fields of carbon compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of pinholes and toxic collapse of corrosion inhibitors, and achieve the effects of simple operation, low toxicity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of graphene oxide grafted melamine corrosion inhibitor: First, mix 50 mg graphene oxide prepared by Hummers method in dimethylformamide to form a suspension with a concentration of 0.1 mg / mL, and ultrasonically disperse it under 200W power 3 hours. Add 50mg of melamine and 100mg of dicyclohexylcarbodiimide, and keep stirring for 24 hours at 50°C. Finally, centrifugation is carried out, and the supernatant is obtained as a solution containing graphene oxide grafted with melamine.

[0035] Self-assembly process of graphene oxide grafted melamine corrosion inhibitor: put the pretreated copper into the solution containing graphene oxide grafted melamine, and after soaking at room temperature for 8 hours, a corrosion inhibition film is formed on the copper surface.

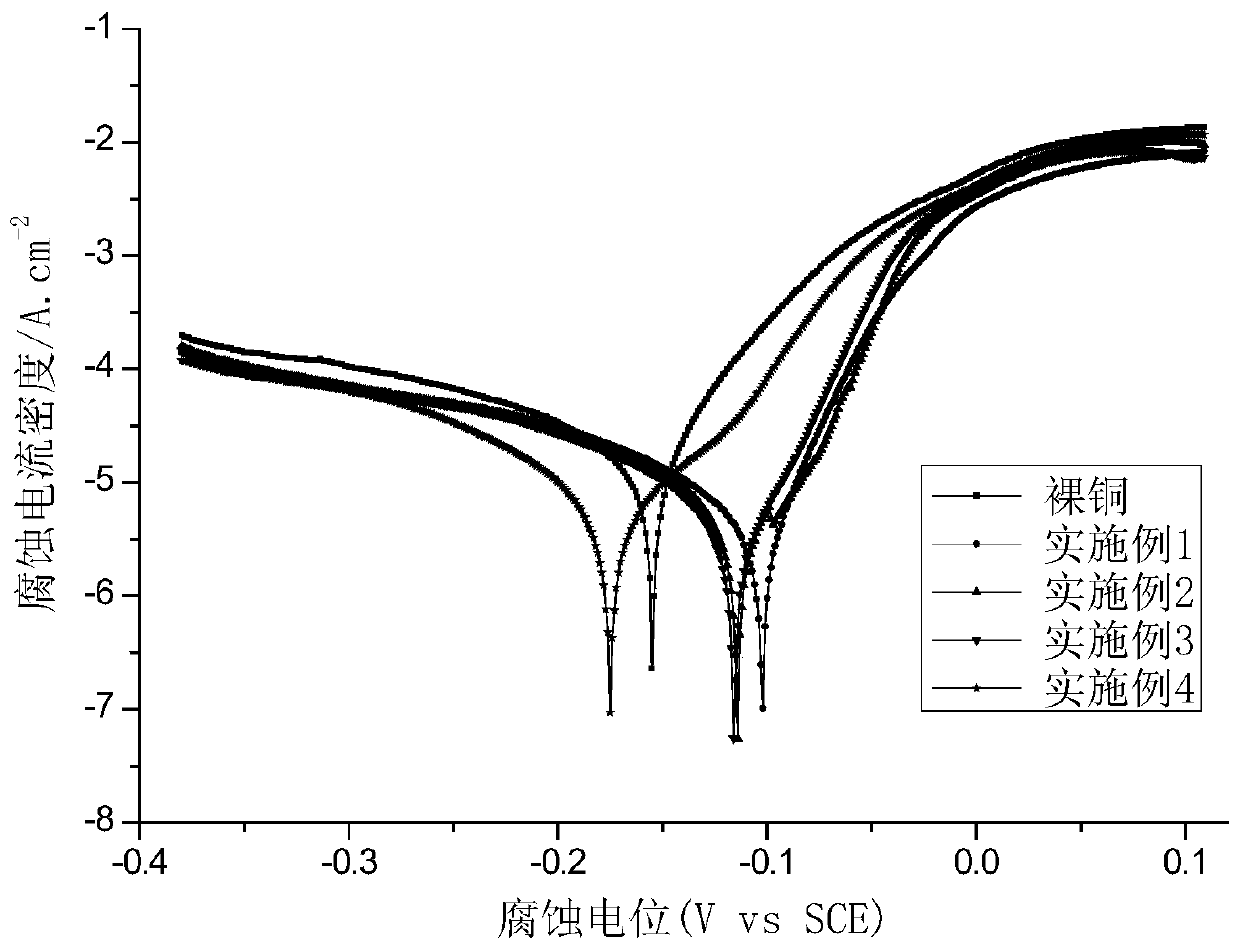

[0036] The Tafel polarization curve is tested by the electrochemical workstation, and the corrosion inhibition efficiency can be calculated as 78.1%.

Embodiment 2

[0038] Preparation of graphene oxide grafted melamine corrosion inhibitor: First, mix 50 mg graphene oxide prepared by Hummers method in dimethylformamide to form a suspension with a concentration of 0.1 mg / mL, and ultrasonically disperse it under 200W power 3 hours. Add 100 mg of melamine and 100 mg of dicyclohexylcarbodiimide, and continue stirring for 24 hours at 50° C. to react. Finally, centrifugation is carried out, and the supernatant is obtained as a solution containing graphene oxide grafted with melamine.

[0039] Self-assembly process of graphene oxide grafted melamine corrosion inhibitor: put the pretreated copper into the solution containing graphene oxide grafted melamine, and after soaking at room temperature for 16 hours, a corrosion inhibition film is formed on the copper surface.

[0040] According to the Tafel polarization curve tested by the electrochemical workstation, it can be calculated that its corrosion inhibition efficiency is 86.9%.

Embodiment 3

[0042] Preparation of graphene oxide grafted melamine corrosion inhibitor: First, mix 50 mg graphene oxide prepared by Hummers method in dimethylformamide to form a suspension with a concentration of 0.1 mg / mL, and ultrasonically disperse it under 200W power 3 hours. Add 50mg of melamine and 200mg of dicyclohexylcarbodiimide, and keep stirring for 24 hours at 50°C. Finally, centrifugation is carried out, and the supernatant is obtained as a solution containing graphene oxide grafted with melamine.

[0043] Self-assembly process of graphene oxide grafted melamine corrosion inhibitor: put the pretreated copper into the solution containing graphene oxide grafted melamine, and after soaking at room temperature for 24 hours, a corrosion inhibition film is formed on the copper surface.

[0044] According to the Tafel polarization curve tested by the electrochemical workstation, it can be calculated that its corrosion inhibition efficiency is 70.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com