Physical simulation and calibration device and method for formation pressure testing

A technology of formation pressure and physical simulation, which is applied in soil material testing, measurement, earthwork drilling and production, etc., can solve the problems of insufficient control precision and precision of confining pressure and wellbore pressure, achieve improvement ability and control precision, and speed up the research and development process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

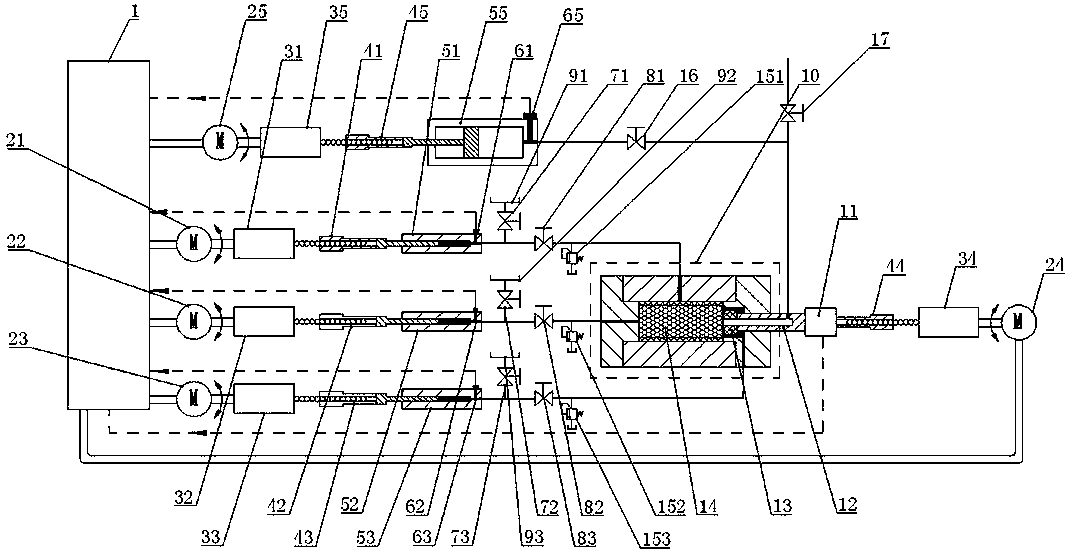

[0035] Such as figure 1 As shown, a physical simulation and calibration device for formation pressure testing, the device includes an external chassis frame, a servo motor for providing power, and a rock core 14 as a test target.

[0036] The device includes a core holder 10 arranged on the chassis frame, a core 14 is arranged in the core holder 10, an annular gap is left between the core 14 and the core holder 10, The annular space is divided into a confining pressure chamber located at the side of the rock core 14 and a formation pressure chamber and an annular pressure chamber at the front and rear ends of the rock core 14 by a sealing gaske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com