Granule drier

A dryer and pellet technology, which is used in drying solid materials, drying gas arrangement, heating to dry solid materials, etc. The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

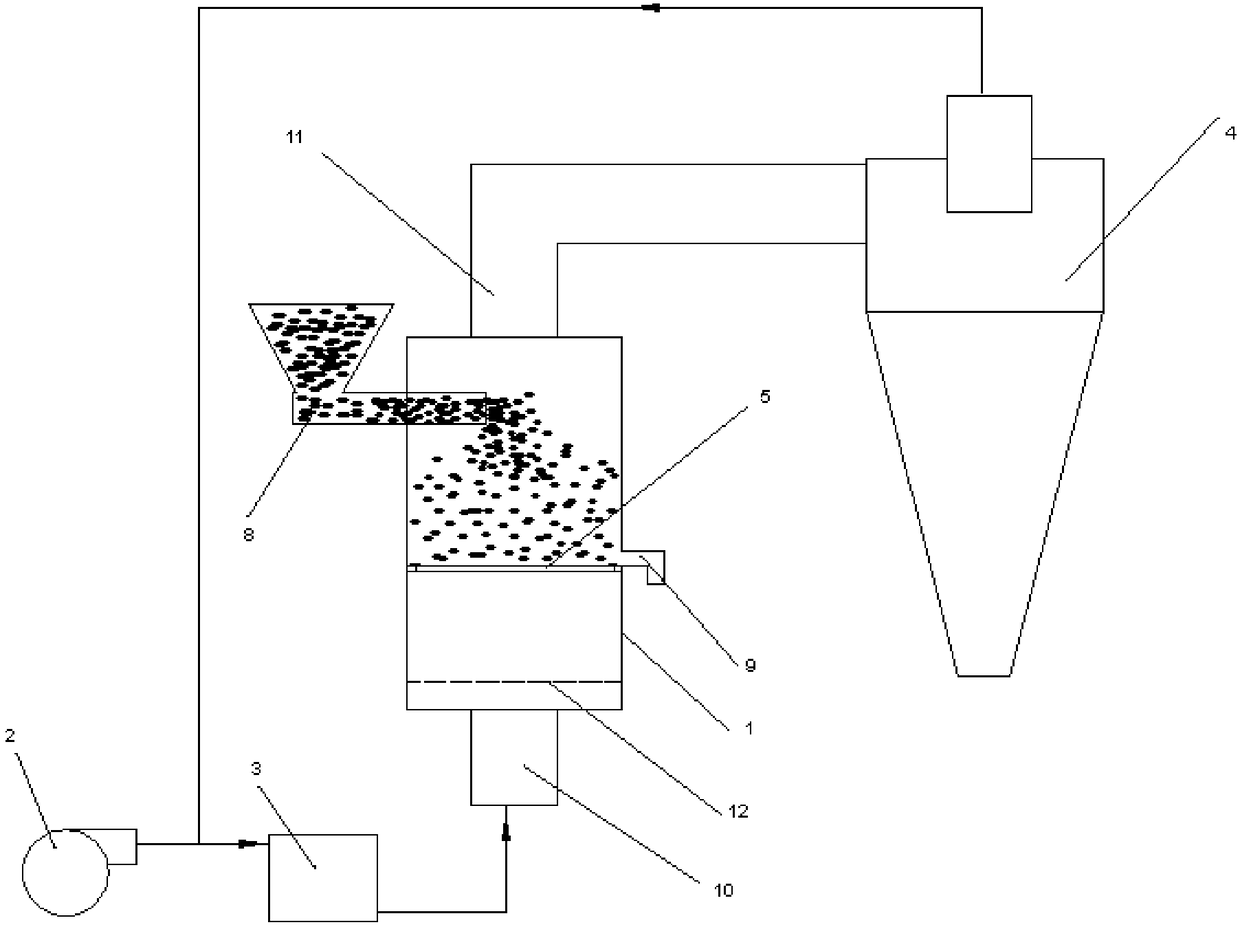

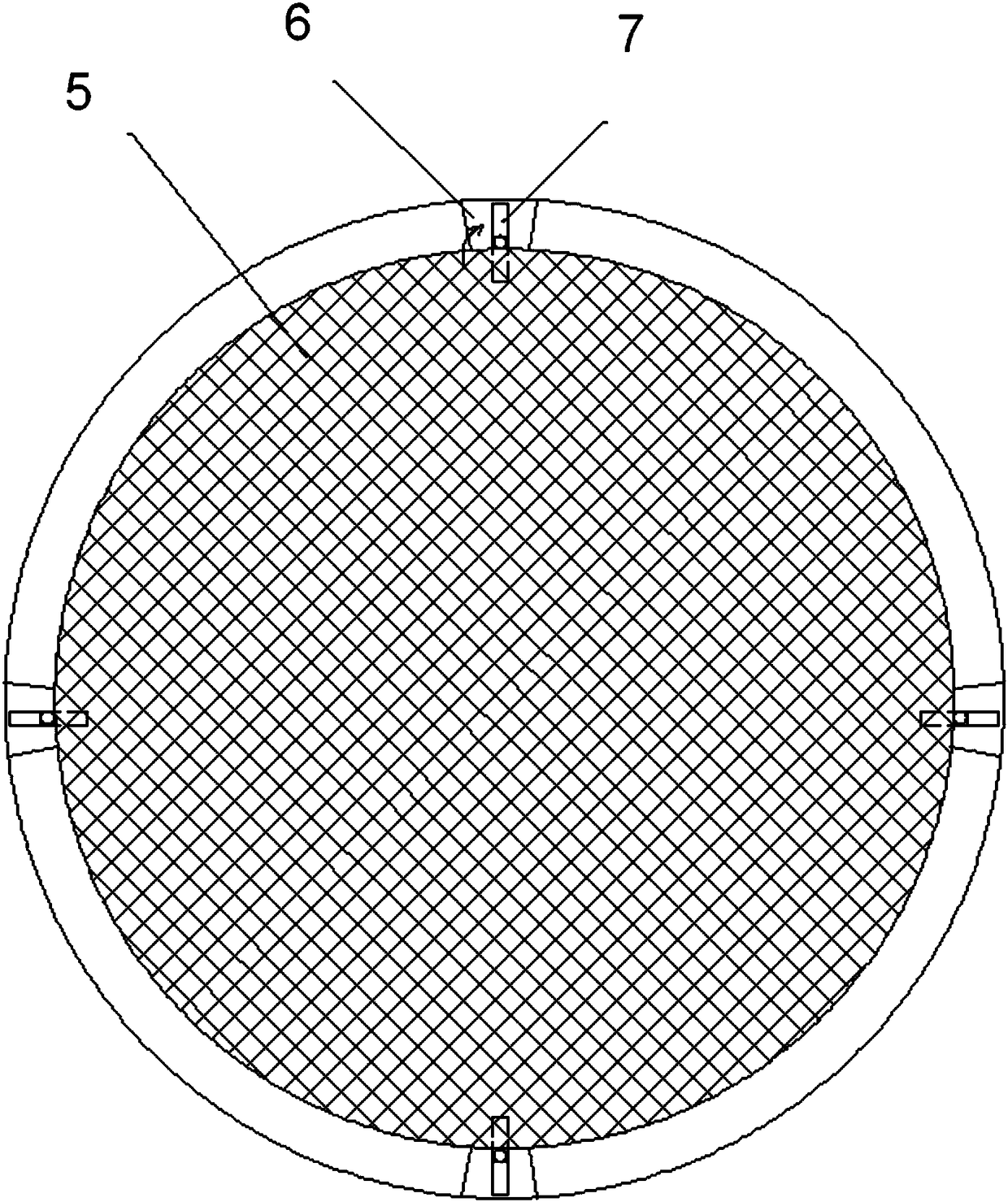

[0018] see figure 1 and figure 2 , a pellet dryer, comprising a cylinder 1, a blower fan 2, a heater 3 and a cyclone separator 4, a pellet distribution grid 5 is arranged in the cylinder, and the pellet distribution grid is made of stainless steel The net and the outer ring support frame are composed of four notches evenly arranged on the lower part of the circumference of the granular material distribution grid plate 5, and the inner wall of the cylinder is provided with a card platform 6 that matches the notches, and the upper surface of the card platform 6 is set There is a rotatable limit stopper 7. When it is necessary to take off the part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com