Borehole fissure permeability sectional pressure-regulating type observation method

A permeability and fracture technology, applied in the direction of permeability/surface area analysis, suspension and porous material analysis, measuring devices, etc., can solve the problems of unstable working process, troublesome operation process, and intertwined pipelines, etc., to achieve detection efficiency and High speed, simple method, and the effect of avoiding winding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

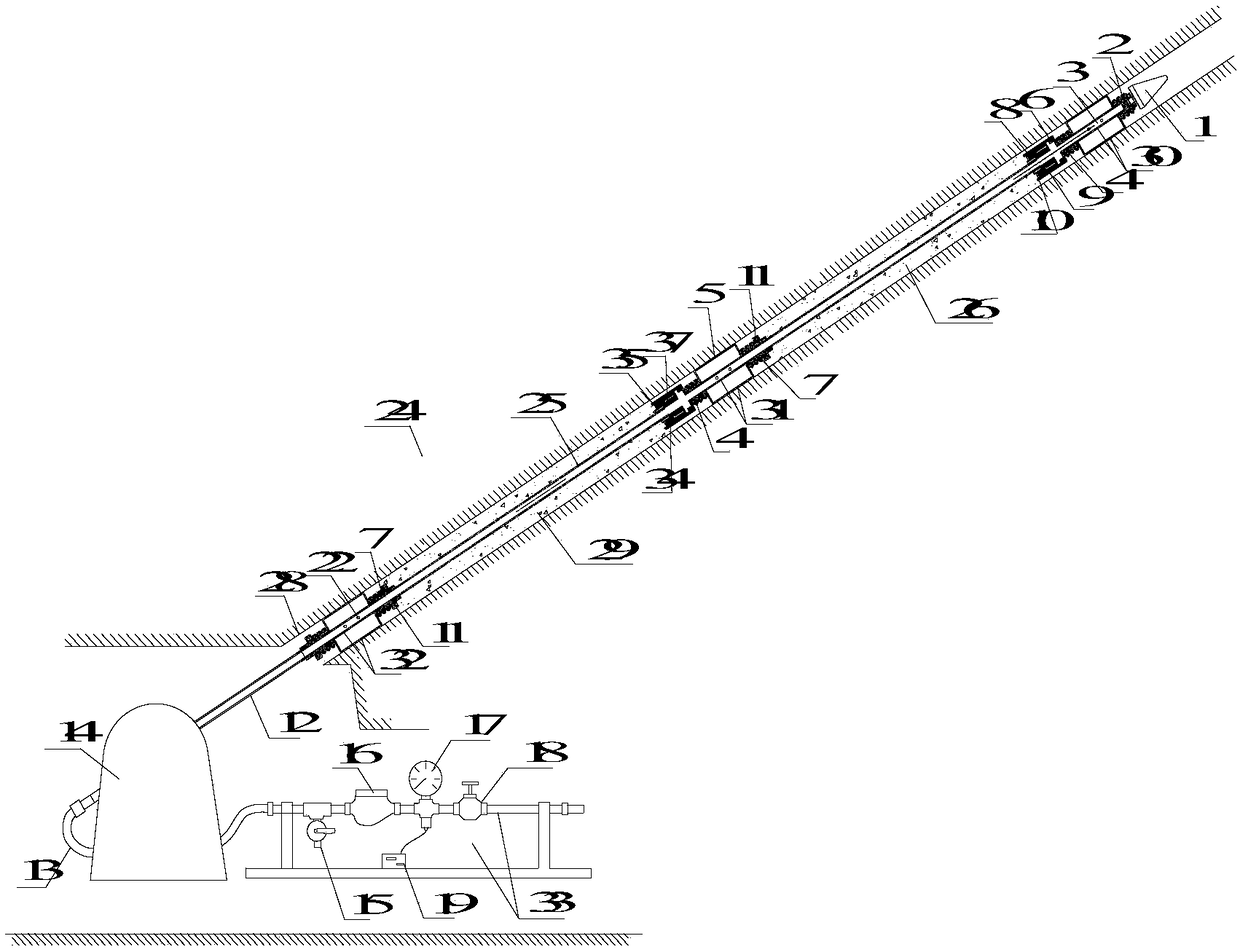

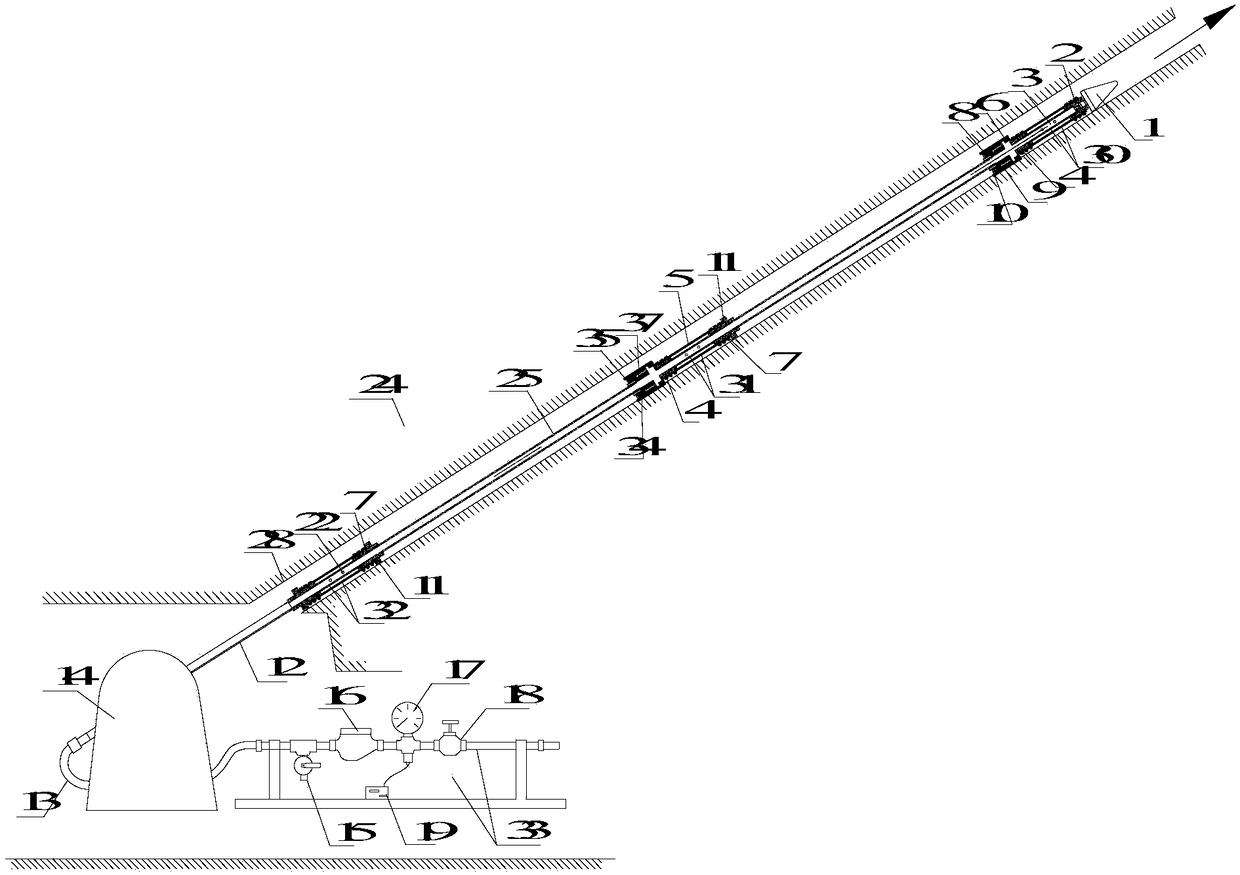

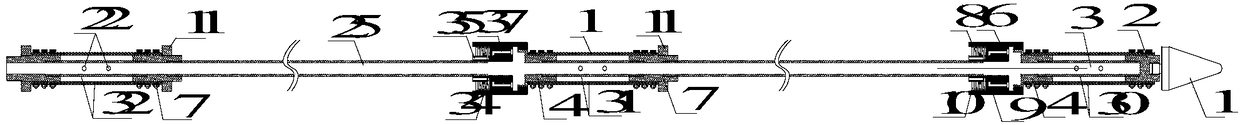

[0053] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0054] A sectioned pressure-regulating observation device for the permeability of borehole 28 fractures and its use method, which mainly includes a plugging test system, a propulsion system, and a supply control system.

[0055] The occluder test system is composed of front occluder 30, middle occluder 31, tail occluder 32, connecting pipe 25 and converter 6. The front occluder 30, middle occluder 31 And the tail occluder 32 and the borehole 28 respectively form the No. 1 water injection cavity 26 and the No. 2 water injection cavity 29. The converter 6 is located at the front part occluder 30 and the middle part occluder 31 tail, and its interior is provided with Inner ring 9, spring 8, cross wire cover 10, sump 34 and water diversion hole 35, said inner ring 9 has a water hole 37, which can be communicate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com