Compound emulsifying paste for cakes and preparation method thereof

An emulsified paste and cake technology, which is applied in baking, dough processing, food science and other directions, can solve the problem of insufficient α-crystal stability of mono- and diglycerol fatty acid esters, insufficient anti-aging performance, and poor quality of cake emulsified paste. To achieve the effect of better taste, improved nutrition and health, and improved competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

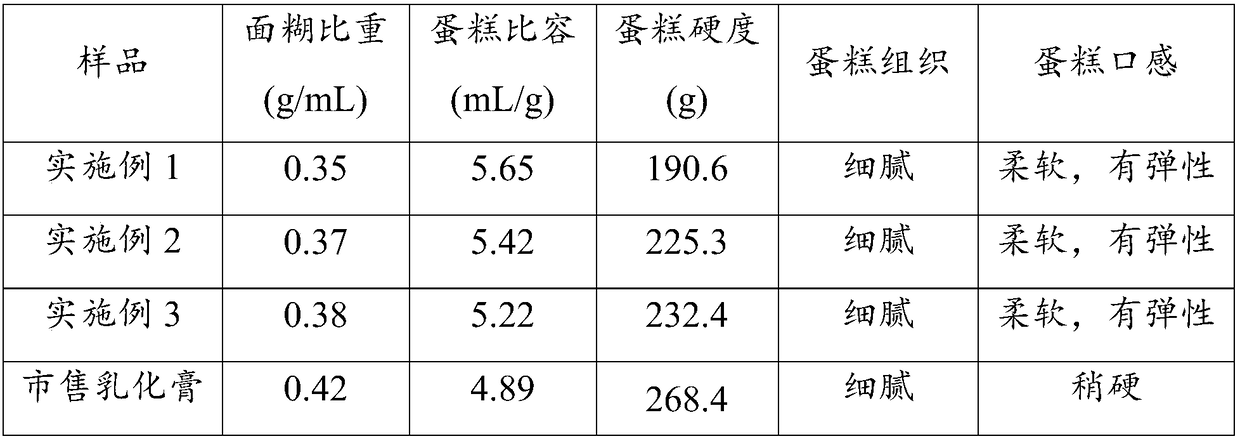

Embodiment 1

[0035] As an embodiment of the compound cake emulsifying cream described in the present invention, the compound cake emulsifying cream described in this embodiment comprises the following components in parts by weight:

[0036] Mono- and Diglycerides of Fatty Acids 15%

[0037] Propylene Glycol 8%

[0038] Propylene glycol fatty acid ester 7%

[0039] Phospholipids 5%

[0040] Soybean polysaccharide 6%

[0041] Sorbitol Liquid 22%

[0042] Deionized water 37%

[0043] Wherein, the mass fraction of sorbitol in the sorbitol liquid is 70%.

[0044] The preparation method of compound cake emulsifying paste described in the present embodiment is:

[0045] (1) Industrial production water is purified by a deionization machine to obtain deionized water (conductivity ≤ 40μs / cm), which is pumped into the water phase pot;

[0046] (2) After the water phase pot is heated up to 75°C, the sorbitol liquid and propylene glycol are pumped in, stirred and mixed evenly to form a water phase...

Embodiment 2

[0051] As an embodiment of the compound cake emulsifying cream described in the present invention, the compound cake emulsifying cream described in this embodiment comprises the following components in parts by weight:

[0052] Mono- and Diglycerides of Fatty Acids 11%

[0053] Propylene Glycol 10%

[0054] Propylene glycol fatty acid ester 7%

[0055] Phospholipids 3%

[0056] Soy Polysaccharide 4%

[0057] Sorbitol Liquid 25%

[0058] Deionized water 40%

[0059] Wherein, the mass fraction of sorbitol in the sorbitol liquid is 70%.

[0060] The preparation method of compound cake emulsifying paste described in the present embodiment is:

[0061] (1) Industrial production water is purified by a deionization machine to obtain deionized water (conductivity ≤ 40μs / cm), which is pumped into the water phase pot;

[0062] (2) Add sorbitol liquid and propylene glycol into deionized water, heat to 70°C, stir and mix evenly to obtain water phase material;

[0063] (3) melting ...

Embodiment 3

[0067] As an embodiment of the compound cake emulsifying cream described in the present invention, the compound cake emulsifying cream described in this embodiment comprises the following components in parts by weight:

[0068] Mono- and Diglycerides of Fatty Acids 12%

[0069] Propylene Glycol 9%

[0070] Propylene glycol fatty acid ester 8%

[0071] Phospholipids 2%

[0072] Soy Polysaccharide 4%

[0073] Sorbitol Liquid 25%

[0074] Deionized water 40%

[0075] Wherein, the mass fraction of sorbitol in the sorbitol liquid is 70%.

[0076] The preparation method of compound cake emulsifying paste described in the present embodiment is:

[0077] (1) Industrial production water is purified by a deionization machine to obtain deionized water (conductivity ≤ 40μs / cm), which is pumped into the water phase pot;

[0078] (2) Add sorbitol liquid and propylene glycol into deionized water, heat to 72°C, stir and mix evenly to obtain water phase material;

[0079] (3) melting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com