Preparation method of light composite concrete panel

A concrete and plate technology, which is applied in the field of preparation of lightweight composite concrete plates, can solve the problems of micro-cracks, inability to meet building structure, broken and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

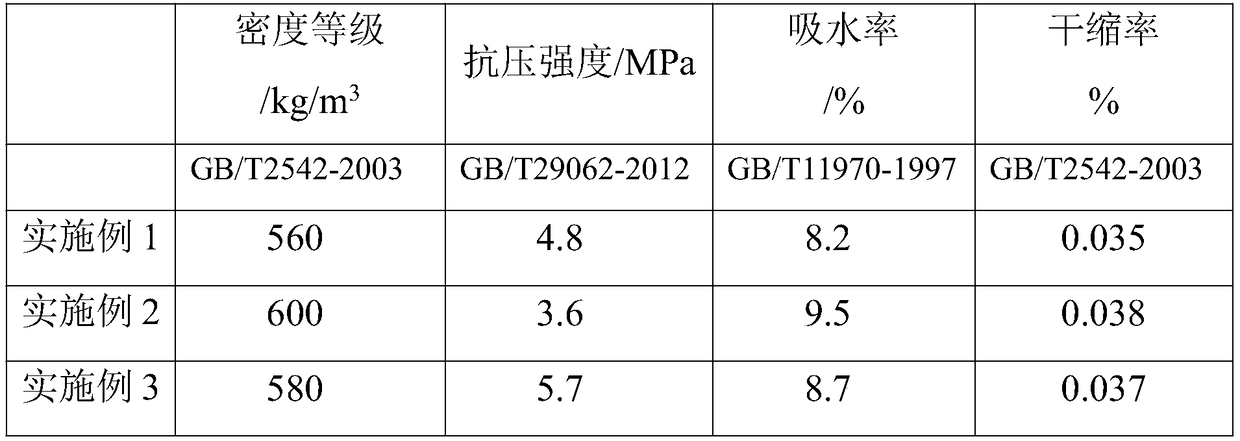

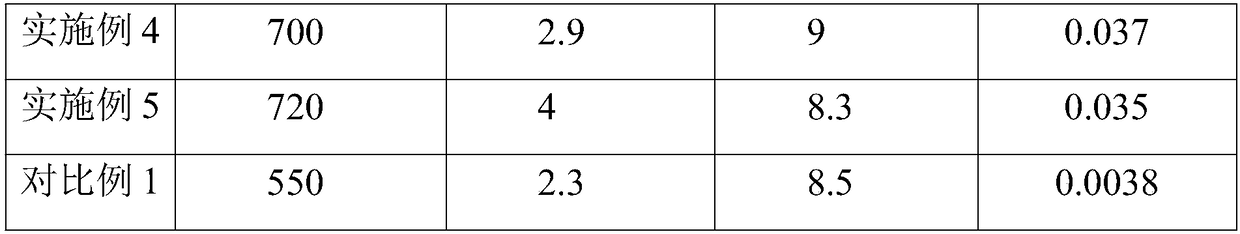

Examples

preparation example Construction

[0019] The present invention also provides a method for preparing the lightweight composite concrete slab, comprising the following steps:

[0020] (1) Soak the waste rubber particles in an acidic solution with a pH of 6-6.5 for 3-5 hours to obtain acidified rubber, mix the acidified rubber and maleic anhydride in water evenly, and then stir and react at 80-120°C for 1-2 hours , to obtain modified rubber;

[0021] (2) 25-45 parts by weight of slag powder, 15-35 parts by weight of cement, 15-30 parts by weight of fine sand, 5-12 parts by weight of diatomaceous earth, 3-15 parts by weight of light calcium carbonate, polyaluminum chloride 3-12 parts by weight, 15-48 parts by weight of light aggregate, and 1-5 parts by weight of reinforcing fiber are uniformly mixed under mechanical stirring conditions to obtain a powder mixture;

[0022] (3) Disperse 0.5-1.5 parts by weight of water reducer and 0-5 parts by weight of other additives in water evenly, then add them to the above po...

Embodiment 1

[0026] (1) Soak 4 parts by weight of waste rubber particles in an acidic solution with a pH of 6 to 6.5 for 4 hours to obtain acidified rubber. After mixing the acidified rubber and 10 parts by weight of maleic anhydride in water, stir and react at 100°C for 1 hour , to obtain modified rubber;

[0027] (2) 35 parts by weight of slag powder, 25 parts by weight of cement, 23 parts by weight of fine sand, 8 parts by weight of diatomaceous earth, 8 parts by weight of light calcium carbonate, 6 parts by weight of polyaluminum chloride, and 10 parts by weight of clay ceramsite (1~5mm), 10 parts by weight of pumice stone (1~5mm), 10 parts by weight of polyethylene foam, 5 parts by weight of polypropylene fiber and modified rubber are uniformly mixed under mechanical stirring conditions to obtain a powder mixture;

[0028] (3) 1.2 parts by weight of polycarboxylate superplasticizer (model PASP-Ca, purchased from Shandong Yuanlian Chemical Co., Ltd.), 1 part by weight of sodium dodecyl...

Embodiment 2

[0031] (1) Soak 3 parts by weight of waste rubber particles in an acidic solution with a pH of 6 to 6.5 for 3 hours to obtain acidified rubber. After mixing the acidified rubber and 9 parts by weight of maleic anhydride in water, stir and react at 120°C 1h, obtain modified rubber;

[0032](2) 25 parts by weight of slag powder, 35 parts by weight of cement, 15 parts by weight of fine sand, 12 parts by weight of diatomaceous earth, 5 parts by weight of polyethylene foam (1 ~ 5mm), 10 parts by weight of castor stalk, polymerized 12 parts by weight of aluminum chloride, 1 part by weight of polyhexamethylene adipamide fiber and modified rubber are uniformly mixed under mechanical stirring to obtain a powder mixture;

[0033] (3) 1.5 parts by weight of polycarboxylate water reducer (model PASP-Ca, purchased from Shandong Yuanlian Chemical Co., Ltd.), 1 part by weight of sodium dodecylbenzenesulfonate, 1 part by weight of calcium stearate, 1 part by weight of hydroxyethyl methyl rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com