Anti-crack mortar and preparation method thereof

A technology for anti-crack mortar and coarse sand, which is applied in the field of anti-crack mortar and its preparation, and can solve problems such as hidden safety hazards, low tensile strength, and falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

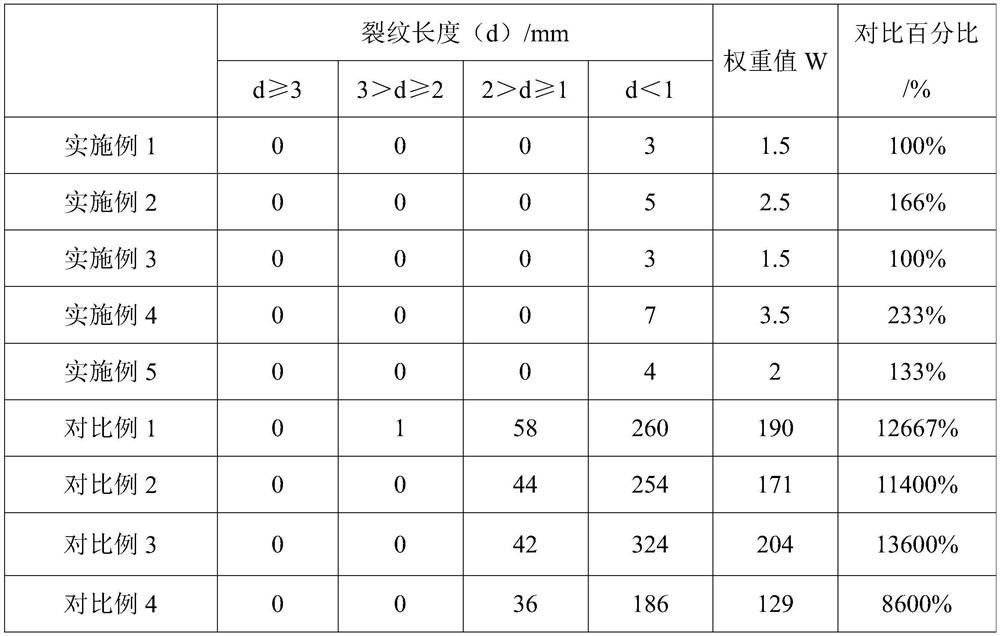

Embodiment 1

[0025] An anti-cracking mortar, comprising the following components in parts by weight:

[0026] 300 parts of Portland cement, 10 parts of PTB emulsion, 15 parts of VAE emulsion, 650 parts of light coarse sand, 100 parts of light fine sand, 2 parts of hydroxypropyl methylcellulose, 15 parts of silane layer glass fiber, poly 10 parts of ethylene glycol graft-modified alkali lignin, 1 part of polycarboxylate water reducing agent, 25 parts of fly ash, 1 part of calcium sulfoaluminate expansion agent, 0.5 part of silicone water repellent, and 330 parts of water.

[0027] Wherein, the preparation method of silane layer glass fiber is as follows:

[0028] Water, methanol, and silane coupling agent KH-570 were mixed and stirred at a volume ratio of 8:1:1 for 40 minutes, then the pH of the system was adjusted to 6 with acetic acid, and the silane hydrolyzed solution was obtained by sealing and standing for 25 hours. The glass fiber was added to the piranha solution, After soaking for...

Embodiment 2

[0034] An anti-cracking mortar, comprising the following components in parts by weight:

[0035] 300 parts of Portland cement, 10 parts of PTB emulsion, 20 parts of VAE emulsion, 650 parts of light coarse sand, 120 parts of light fine sand, 2 parts of hydroxypropyl methylcellulose, 20 parts of carbon fiber with silane layer, polyethylene 10 parts of glycol graft modified alkali lignin, 2 parts of polycarboxylate water reducing agent, 30 parts of fly ash, 1 part of calcium sulfoaluminate expansion agent, 1 part of silicone water repellent, and 330 parts of water.

[0036] Wherein, the preparation method of carbon fiber containing silane layer is as follows:

[0037] Water, methanol, and silane coupling agent KH-560 were mixed and stirred at a volume ratio of 8:1:1 for 40 minutes, then the pH of the system was adjusted to 6 with acetic acid, and the silane hydrolyzed solution was obtained by sealing and standing for 25 hours. The carbon fibers were added to the piranha solution ...

Embodiment 3

[0043] An anti-cracking mortar, comprising the following components in parts by weight:

[0044] 280 parts of Portland cement, 5 parts of PTB emulsion, 10 parts of VAE emulsion, 600 parts of light coarse sand, 100 parts of light fine sand, 1 part of hydroxypropyl methylcellulose, 10 parts of steel fiber with silane layer, poly 5 parts of ethylene glycol graft modified alkali lignin, 1 part of polycarboxylate water reducer, 20 parts of fly ash, 0.5 part of calcium sulfoaluminate expansion agent, 0.5 part of silicone water repellent, and 300 parts of water.

[0045]Wherein, the preparation method of silane layer steel fiber is as follows:

[0046] Water, methanol, and silane coupling agent KH-550 were mixed and stirred at a volume ratio of 6:1:1 for 20 minutes, then the pH of the system was adjusted to 4 with acetic acid, and the silane hydrolyzed solution was obtained by sealing and standing for 20 hours. The steel fibers were added to the piranha solution, After soaking for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com