Method for preparing inorganic wall body insulating material

A technology for thermal insulation materials and walls, which is applied in the field of preparation of inorganic wall thermal insulation materials, and can solve problems such as temperature changes, cracks, and high water absorption of cracked walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

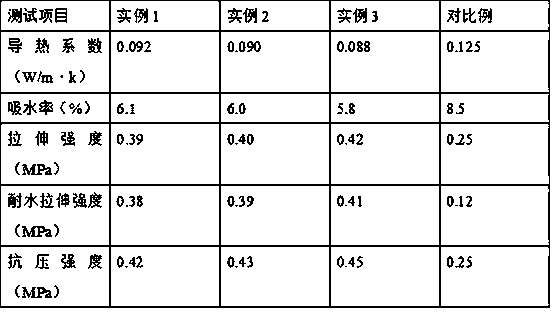

Examples

example 1

[0023] Weigh perlite and put it into a high-temperature furnace, heat up to 1000°C, and calcinate for 1 hour to obtain expanded perlite. Mix expanded perlite and sodium hydroxide solution with a mass fraction of 30% at a mass ratio of 1:5 and put In the high-pressure reactor, seal the reactor, heat it up to 150°C under the condition of a pressure of 1.5MPa, and react at high temperature and high pressure for 20 minutes; after the above reaction is completed, filter to obtain the filter residue and filtrate respectively. Repeatedly rinse with water for 3 times, then mix the washed filter residue and castor oil in an equal mass ratio to obtain a mixture, and put the mixture into a fermenter; 65% of the treatment room, stand for rancidity treatment for 5 days, after the rancidity treatment, seal the mouth of the fermentation tank, and leave it for fermentation at a temperature of 38°C for 5 days. Rinse with water for 3 times, put it into an oven, and dry at 105°C for 1 hour to ob...

example 2

[0025]Weigh perlite and put it into a high-temperature furnace, heat up to 1150°C, and calcinate for 1.5 hours to obtain expanded perlite. Mix expanded perlite and sodium hydroxide solution with a mass fraction of 30% in a mass ratio of 1:5 and put Put it into a high-pressure reactor, seal the reactor, heat up to 155°C under the condition of a pressure of 1.7MPa, and react at high temperature and high pressure for 25min; Repeatedly rinse 4 times with deionized water, then mix the washed filter residue and castor oil in an equal mass ratio to obtain a mixture, and put the mixture into a fermenter; In a treatment room with a humidity of 70%, let it stand for rancidity treatment for 6 days. After the rancidity treatment, seal the mouth of the fermentation tank and leave it for fermentation at a temperature of 39°C for 6 days. After the above fermentation is completed, take out the fermentation product and use it Rinse with deionized water for 4 times, put it into an oven, and dry...

example 3

[0027] Weigh perlite and put it into a high-temperature furnace, heat up to 1300°C, and calcinate for 2 hours to obtain expanded perlite. Mix expanded perlite and sodium hydroxide solution with a mass fraction of 30% at a mass ratio of 1:5 and put it in In the high-pressure reactor, seal the reactor, heat up to 160°C under a pressure of 1.8 MPa, and react at high temperature and high pressure for 30 minutes; after the above reaction is completed, filter to obtain the filter residue and filtrate respectively, and the filtrate is for use. Repeatedly rinse with water for 5 times, then mix the washed filter residue and castor oil in an equal mass ratio to obtain a mixture, and put the mixture into a fermenter; 80% of the treatment room, stand for rancidity treatment for 7 days, after the rancidity treatment, seal the mouth of the fermentation tank, and leave it for fermentation at a temperature of 40°C for 7 days. After rinsing with water for 5 times, put it into an oven and dry a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com