Method for improving powder potash magnesium sulphate fertilizer granularity

A potassium and magnesium sulfate fertilizer and particle size technology, which is applied in the field of salt chemical industry, can solve problems such as dust, achieve the effects of reducing dust, improving the working environment, and facilitating production cost management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

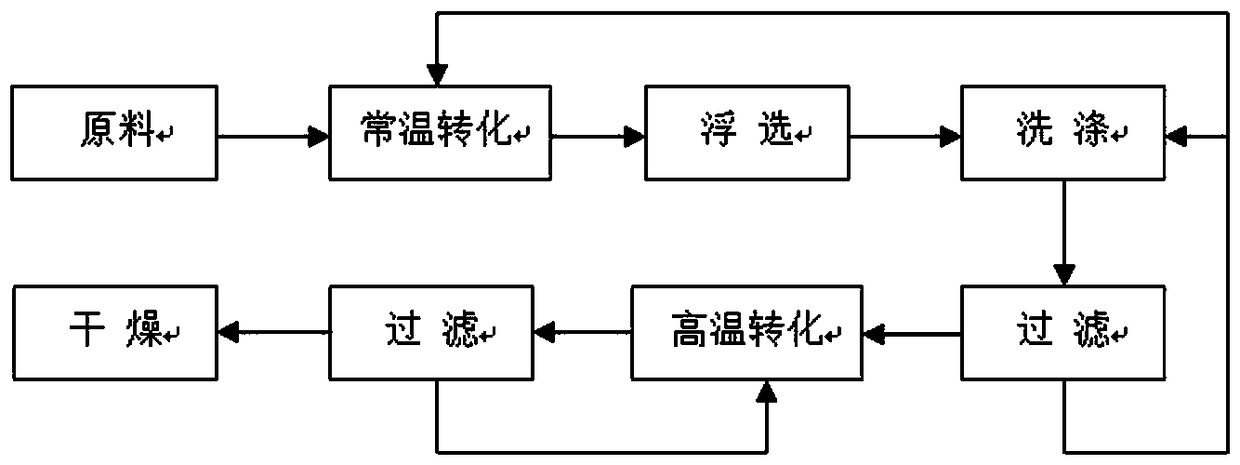

[0011] A kind of method that improves powder potassium magnesium sulfate fertilizer particle size, refer to figure 1 , the process steps are as follows: 1) Magnesium sulfate subtype potassium-magnesium mixed salt is prepared by the process of "turning first and then floating" to produce soft potash concentrate foam containing about 70% langbeinite; 2) making soft potash concentrate obtained in step 1) Mineral foam, fresh water and washing return mother liquor are mixed according to the weight ratio of 5:1:4, and washed for 30 minutes; 3) The pulp prepared in step 2) is filtered and separated, and part of the filtrate is returned to normal temperature for transformation, and the other part is returned to the washing tank to adjust the concentration; 4) Put the filter cake obtained in step 3) into a high-temperature stirring tank, add 80°C hot water with 70% of the weight of the filter cake, control the conversion temperature in the range of 50-55°C, and mix and stir for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com