Preparation method of a pulp capping material in vitro evaluation model

A technique for evaluating models and material bodies, applied in biochemical equipment and methods, cell dissociation methods, microorganisms, etc. Capacitance, more scientific evaluation results, and improved efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

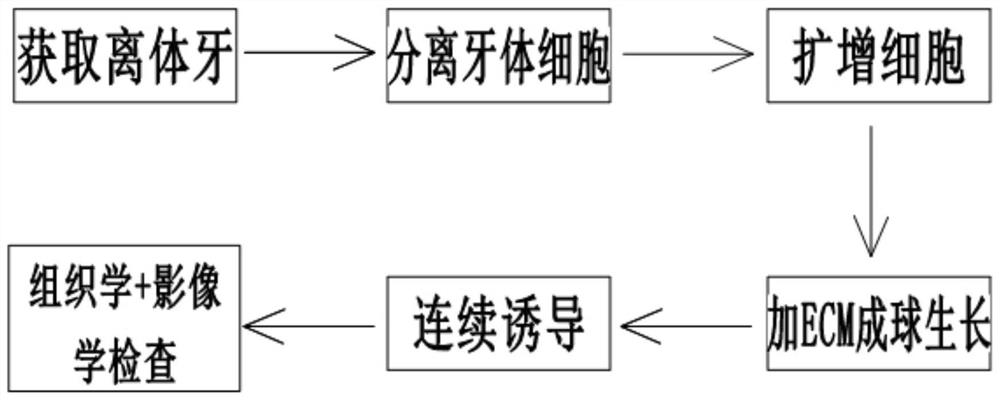

[0026] Example workflow as attached figure 1 As shown, the present invention applies for a method for preparing a pulp capping material in vitro evaluation model, and the specific steps are:

[0027] The first step is to separate and obtain human dental pulp cells, collect freshly extracted orthodontic teeth and impacted teeth in the dental clinic, take out the dental pulp, and isolate and culture human dental pulp cells by using a modified enzyme-digested tissue block method. When the cells cover about 80%-90% of the bottom of the bottle, they are routinely subcultured and expanded for culture.

[0028] The specific method is as follows: (1) Take freshly extracted healthy and complete impacted molars without periodontal disease or premolars extracted due to orthodontics in the dental clinic. The age of the patients is controlled between 11-22 years old. Clean and disinfect inside,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com