Battery box of electric vehicle and heat dissipating and heating system and method thereof

A technology for electric vehicles and battery boxes, applied to secondary batteries, circuits, electrical components, etc., can solve problems such as vehicle failure, internal short circuit, water cooling fluid leakage, etc., achieve high safety and reliability, wide operating temperature range, Fast charging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Below in conjunction with embodiment, further illustrate the present invention.

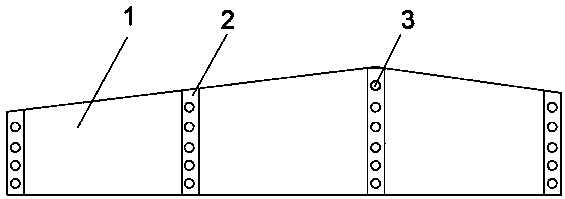

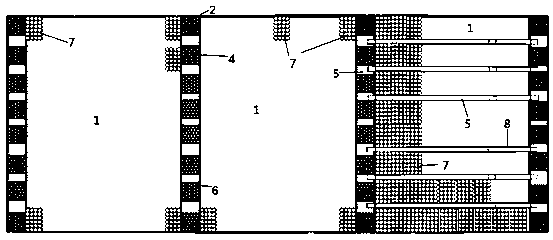

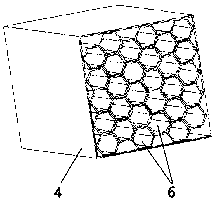

[0067] see figure 1 , figure 2 , image 3 , Figure 4 It can be known that a battery box for an electric vehicle according to the present invention has a shell structure, and a heat exchange area 2 and a battery installation area 1 are arranged in the shell of the battery box. The heat exchange areas 2 are arranged at intervals, and the heat exchange area 2 The two ends of the battery box are connected to the side wall of the battery box. The interval between the heat exchange area 2 and the heat exchange area 2 is the battery installation area 1. The heat exchange area 2 is provided with heat dissipation units 4 arranged at intervals. The interval between heat pipes and cold pipe installation areas 5, heat dissipation unit 4 is provided with heat dissipation chambers 6 adjacent to each other, heat pipes, cold pipe installation areas 5 still have gaps after installing heat pipes 10 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com