Aluminum phosphide fumigant convenient to handle

A technology of aluminum phosphide and fumigant, applied in the field of fumigation, can solve the problems of human and animal poisoning, high treatment cost, complicated process, etc., and achieve the effects of significant water absorption and swelling effect, low aluminum phosphide content, and high residue treatment rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

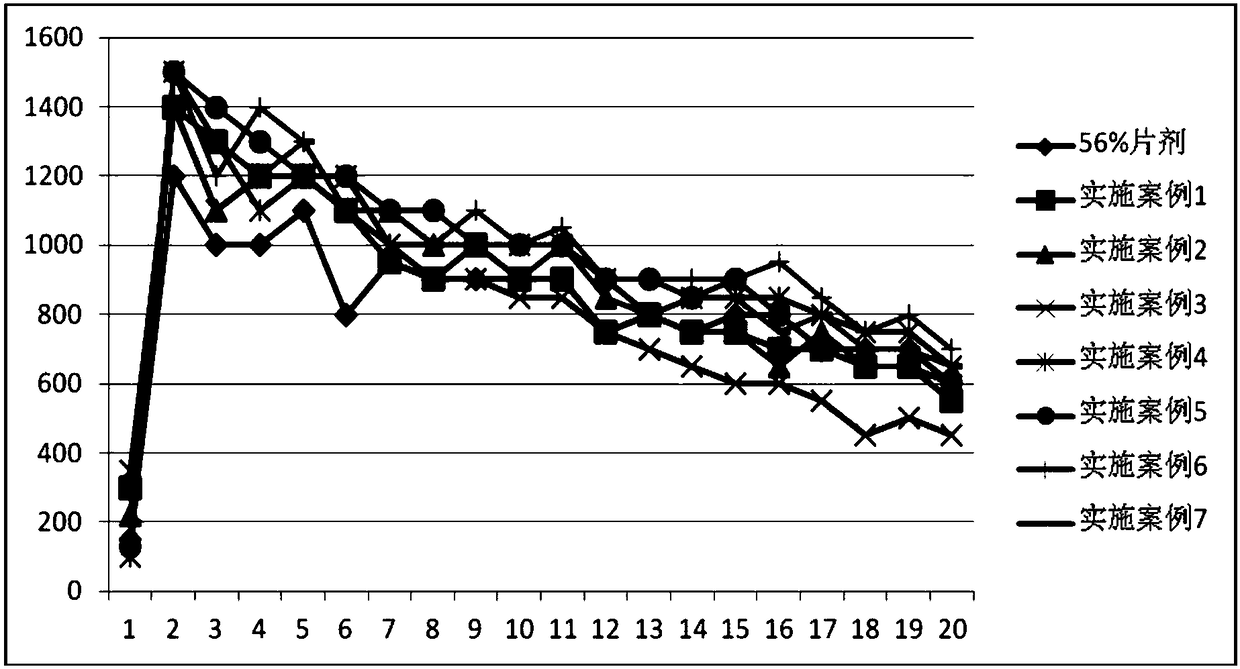

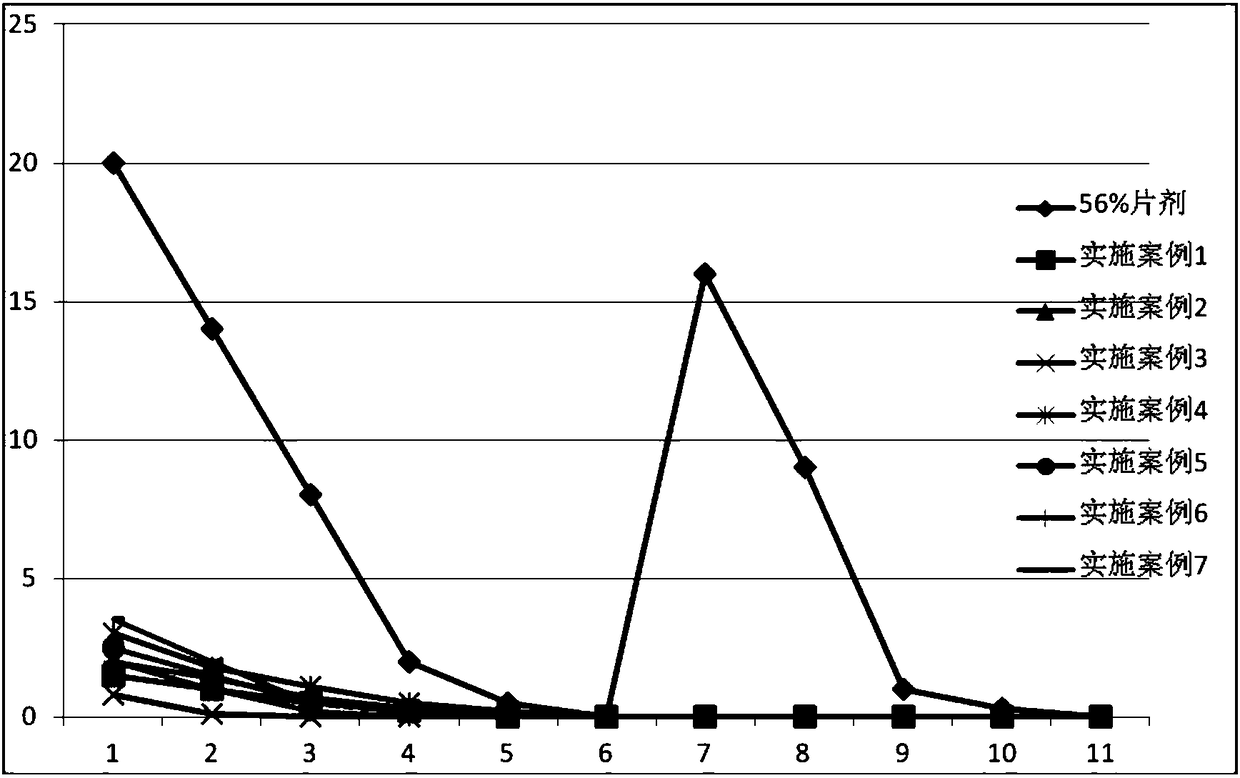

Examples

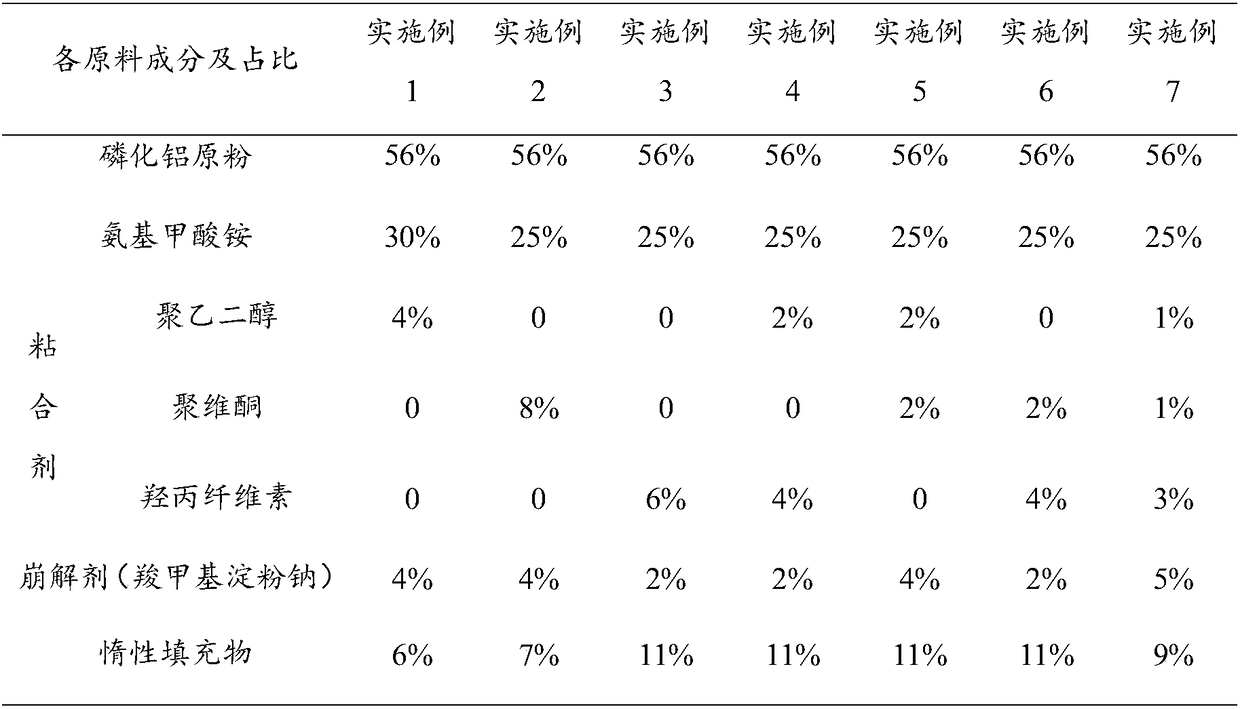

Embodiment 1

[0017] A kind of aluminum phosphide fumigant which is easy to handle, every 100 parts of agent, 56 parts of aluminum phosphide raw powder, 30 parts of ammonium carbamate, 4 parts of polyethylene glycol, 4 parts of sodium carboxymethyl starch, 6 parts of inert filler .

Embodiment 2

[0019] An aluminum phosphide fumigant that is easy to handle, for every 100 parts of the agent, there are 56 parts of aluminum phosphide raw powder, 25 parts of ammonium carbamate, 8 parts of povidone, 4 parts of sodium carboxymethyl starch, and 7 parts of inert filler.

Embodiment 3

[0021] A convenient aluminum phosphide fumigant, every 100 parts of agent, 56 parts of aluminum phosphide raw powder, 25 parts of ammonium carbamate, 6 parts of hydroxypropyl cellulose, 2 parts of sodium carboxymethyl starch, 11 parts of inert filler .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com