Active biological product and processing method thereof

A technology of biological products and processing methods, applied in food science and other directions, can solve the problems of reducing the content of natural active substances, burdening the human body, and restricting applications, and achieve the effect of preventing protein denaturation, improving processing efficiency, and maintaining nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

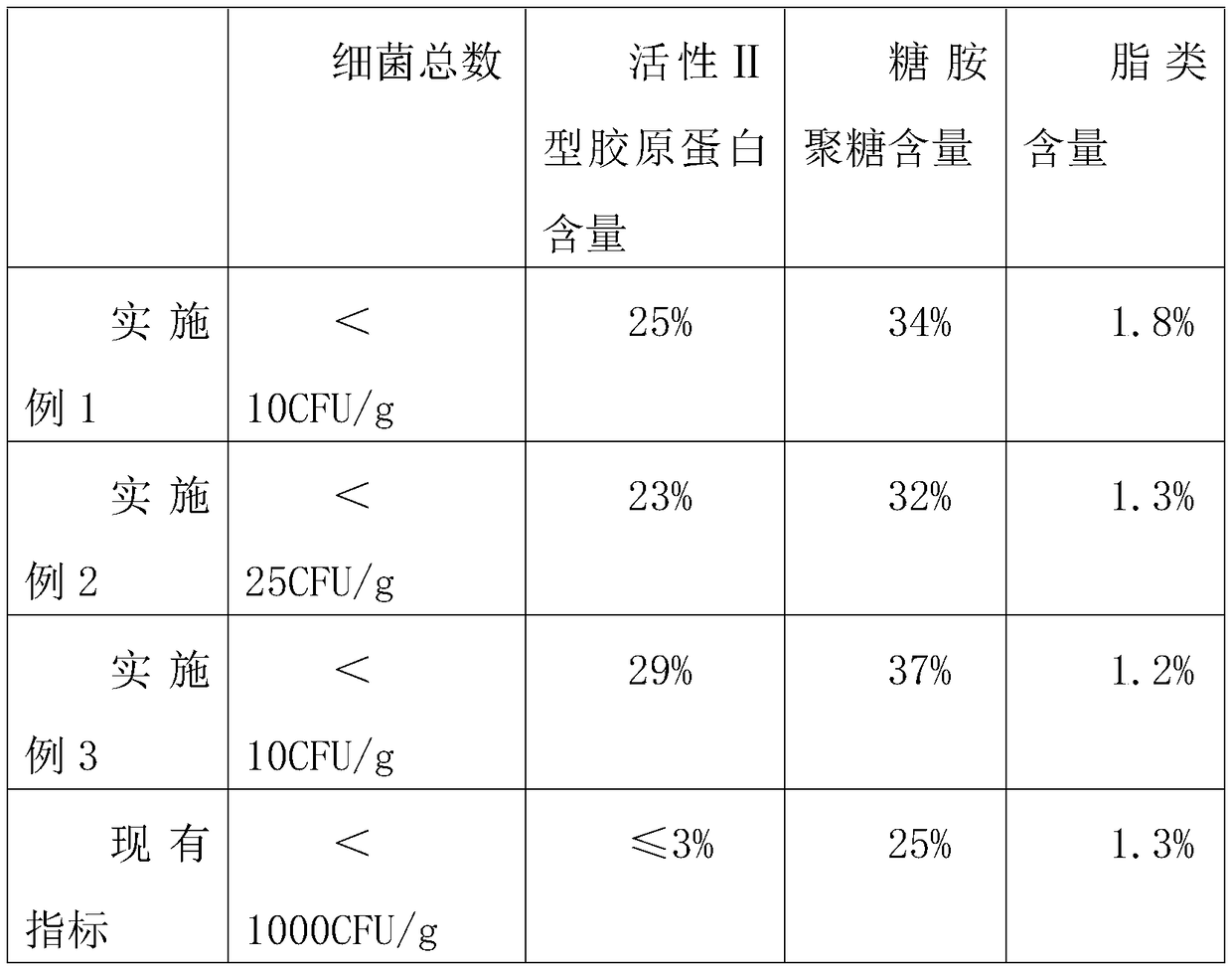

Embodiment 1

[0024] An active biological product, its ingredients include: rich in active type II collagen, glycosaminoglycan and a small amount of water.

[0025] A processing method of an active biological product, the processing method comprising the following steps:

[0026] ①Cleaning: Take chicken articular cartilage, remove hard bones, residual meat and fat tissue, stir and clean, and drain;

[0027] ② Coarse crushing: cut the cartilage into about 1cm in size;

[0028] ③Removing the periosteum: Stir and mix the chopped cartilage with sodium chloride or potassium chloride and VC at a mass ratio of 20:1:0.5 for 1 hour, and wash with drinking water until the conductivity is below 500 μs / cm;

[0029] ④Removing impurity protein: add one or several low-salt organic acid solutions with 2 times the volume of cartilage weight (v / w) to soak, the concentration is controlled at 0.1mol / L, supplemented by ultrasonic treatment, so that the cartilage tissue is relaxed and expanded, and stirred 1 h...

Embodiment 2

[0037] An active biological product, its ingredients include: rich in active type II collagen, glycosaminoglycan and a small amount of water.

[0038] A processing method of an active biological product, the processing method comprising the following steps:

[0039] ①Cleaning: Take chicken articular cartilage, remove hard bones, residual meat and fat tissue, stir and clean, and drain;

[0040] ② Coarse crushing: cut the cartilage into about 1cm in size;

[0041] ③Removing the periosteum: Stir and mix the chopped cartilage with sodium chloride or potassium chloride and VC at a mass ratio of 20:1:0.5 for 1 hour, and wash with drinking water until the conductivity is below 500 μs / cm;

[0042] ④ Remove impurities: add one or several low-salt organic acid solutions with 4 times the volume of cartilage weight (v / w) to soak, the concentration is controlled at 0.5mol / L, supplemented by ultrasonic treatment, so that the cartilage tissue is relaxed and expanded, and stirred 1.5 hours,...

Embodiment 3

[0050] An active biological product, its ingredients include: rich in active type II collagen, glycosaminoglycan and a small amount of water.

[0051] A processing method of an active biological product, the processing method comprising the following steps:

[0052] ①Cleaning: Take fresh chicken articular cartilage, remove hard bones, residual meat and fat tissue, stir and clean, and drain;

[0053] ② Coarse crushing: cut the cartilage into about 1cm in size;

[0054] ③Removing the periosteum: Stir and mix the chopped cartilage with sodium chloride or potassium chloride and VC at a mass ratio of 20:1:0.5 for 2 hours, and wash with drinking water until the conductivity is below 500 μs / cm;

[0055] ④ Remove impurities: Add one or several low-salt organic acid solutions with 5 times the volume of cartilage weight (v / w) to soak, the concentration is controlled at 1.0mol / L, supplemented by ultrasonic treatment, so that the cartilage tissue is relaxed, expanded, and stirred 2 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com