Nursing paper diaper

A technology for diapers and nursing solution, applied in the field of nursing diapers, can solve the problems of unfavorable baby's health, high cost, skin irritation, etc., and achieve the effects of reducing diaper rash and red buttocks, reducing reddish buttocks, and removing internal heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

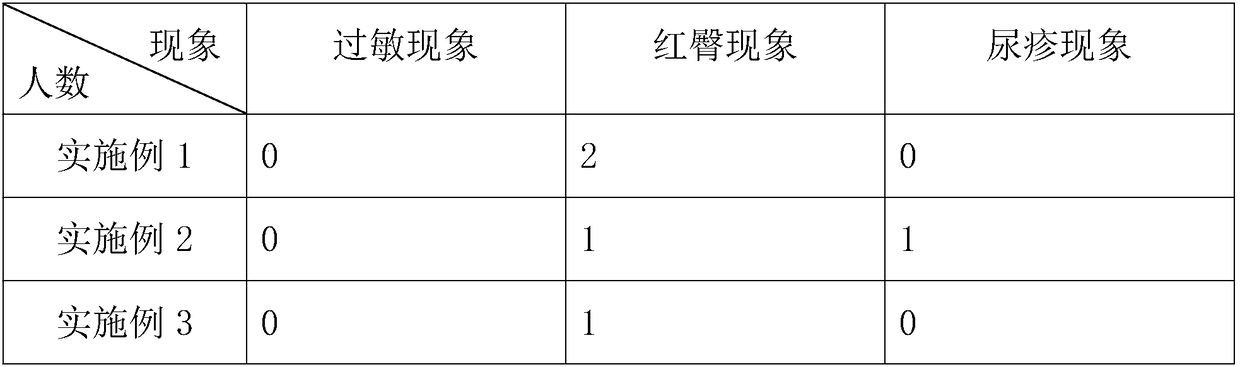

Embodiment 1

[0022] A nursing diaper, comprising a liquid-permeable soft cotton surface layer, a care layer, an absorbent body and a liquid-impermeable bottom layer arranged sequentially from top to bottom;

[0023] The absorbent body includes a diversion core layer and an absorbent core layer. Specifically, the absorbent core layer includes an upper puffed paper, a first polymer absorbent resin, fluffy cotton, a second polymer absorbent resin, and a lower puffed paper compounded sequentially from top to bottom. , further, the diversion core layer is composed of non-woven fabric and bamboo fiber spunlace non-woven fabric;

[0024] The care layer is formed by soaking the non-woven fabric in the care solution and then drying it. Specifically, the care layer is made by soaking the non-woven fabric in the care solution for 36 hours, and then drying at a temperature of 85°C for 50 minutes;

[0025] The nursing solution includes the following raw materials in parts by weight: 22 parts of Herba D...

Embodiment 2

[0032] A nursing diaper, comprising a liquid-permeable soft cotton surface layer, a care layer, an absorbent body and a liquid-impermeable bottom layer arranged sequentially from top to bottom;

[0033] The absorbent body includes a diversion core layer and an absorbent core layer. Specifically, the absorbent core layer includes an upper puffed paper, a first polymer absorbent resin, fluffy cotton, a second polymer absorbent resin, and a lower puffed paper compounded sequentially from top to bottom. , further, the diversion core layer is composed of non-woven fabric and bamboo fiber spunlace non-woven fabric;

[0034] The care layer is formed by soaking the non-woven fabric in the care solution and then drying it. Specifically, the care layer is made by soaking the non-woven fabric in the care solution for 32 hours, and then drying it for 35 minutes at a temperature of 100°C;

[0035] The care solution includes the following raw materials in parts by weight: 18 parts of Herba ...

Embodiment 3

[0042] A nursing diaper, comprising a liquid-permeable soft cotton surface layer, a care layer, an absorbent body and a liquid-impermeable bottom layer arranged sequentially from top to bottom;

[0043] The absorbent body includes a diversion core layer and an absorbent core layer. Specifically, the absorbent core layer includes an upper puffed paper, a first polymer absorbent resin, fluffy cotton, a second polymer absorbent resin, and a lower puffed paper compounded sequentially from top to bottom. , further, the diversion core layer is composed of non-woven fabric and bamboo fiber spunlace non-woven fabric;

[0044] The care layer is formed by soaking the non-woven fabric in the care solution and then drying it. Specifically, the care layer is made by soaking the non-woven fabric in the care solution for 34 hours, and then drying at a temperature of 90°C for 42 minutes;

[0045] The care solution includes the following raw materials in parts by weight: 20 parts of Herba Cormat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com