Use method of dry-type purification system for casting flue dust recovery

A purification system and technology for soot, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of polluted water source, large air supply pressure of fans, explosion of filter screen, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

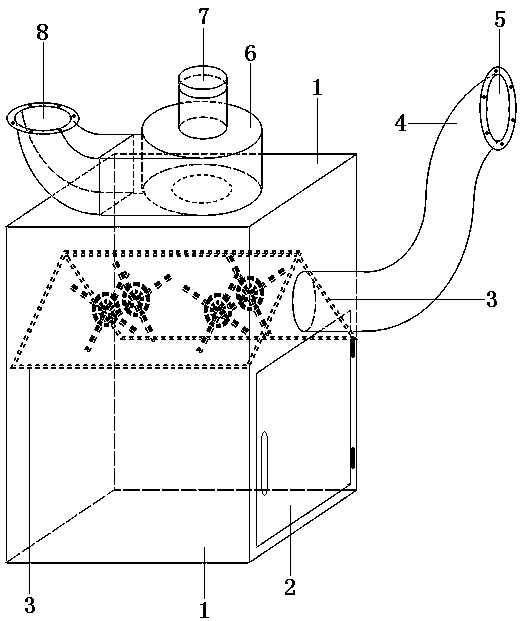

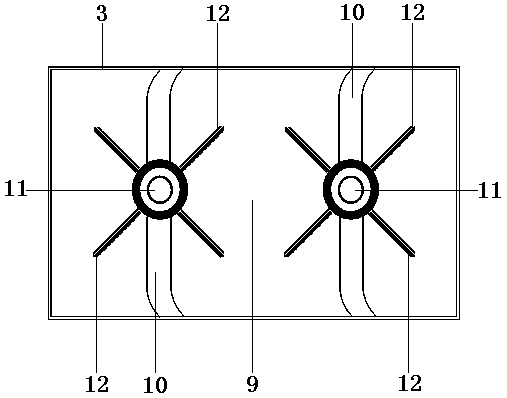

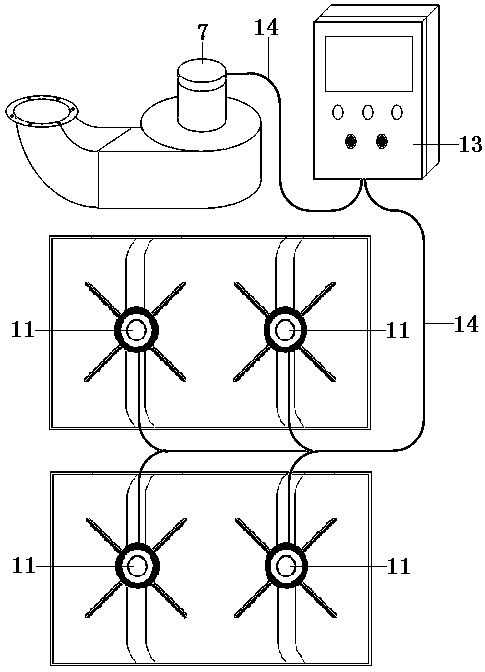

[0013] Foundry dust recovery dry purification system: including storage box 1, storage box door 2, herringbone bracket 3, air inlet pipe 4, air inlet 5, centrifugal fan 6, high-speed motor 7, air outlet 8, filter 9, motor Support 10, geared motor 11, brush bar 12, distribution box 13, power cord 14, storage box is connected with storage box door, herringbone support, air inlet pipe, centrifugal fan, herringbone support is connected with filter screen, motor support, The motor bracket is connected with the deceleration motor, the deceleration motor is connected with the brush bar, the air inlet pipe is connected with the air inlet, the centrifugal fan is connected with the high-speed motor and the air outlet, and the power distribution box is connected with the high-speed motor and the deceleration motor through the power line.

[0014] The storage box is in the shape of a cuboid, and a herringbone bracket equal to the size of the box body is installed at the upper 2 / 3 of the in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap