High-strength polyethylene microporous film and preparation method and application thereof

A high-strength polyethylene, microporous membrane technology, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problems of shortened service life, low strength, limitations, etc., to solve the problems of shortened service life, wide application range, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

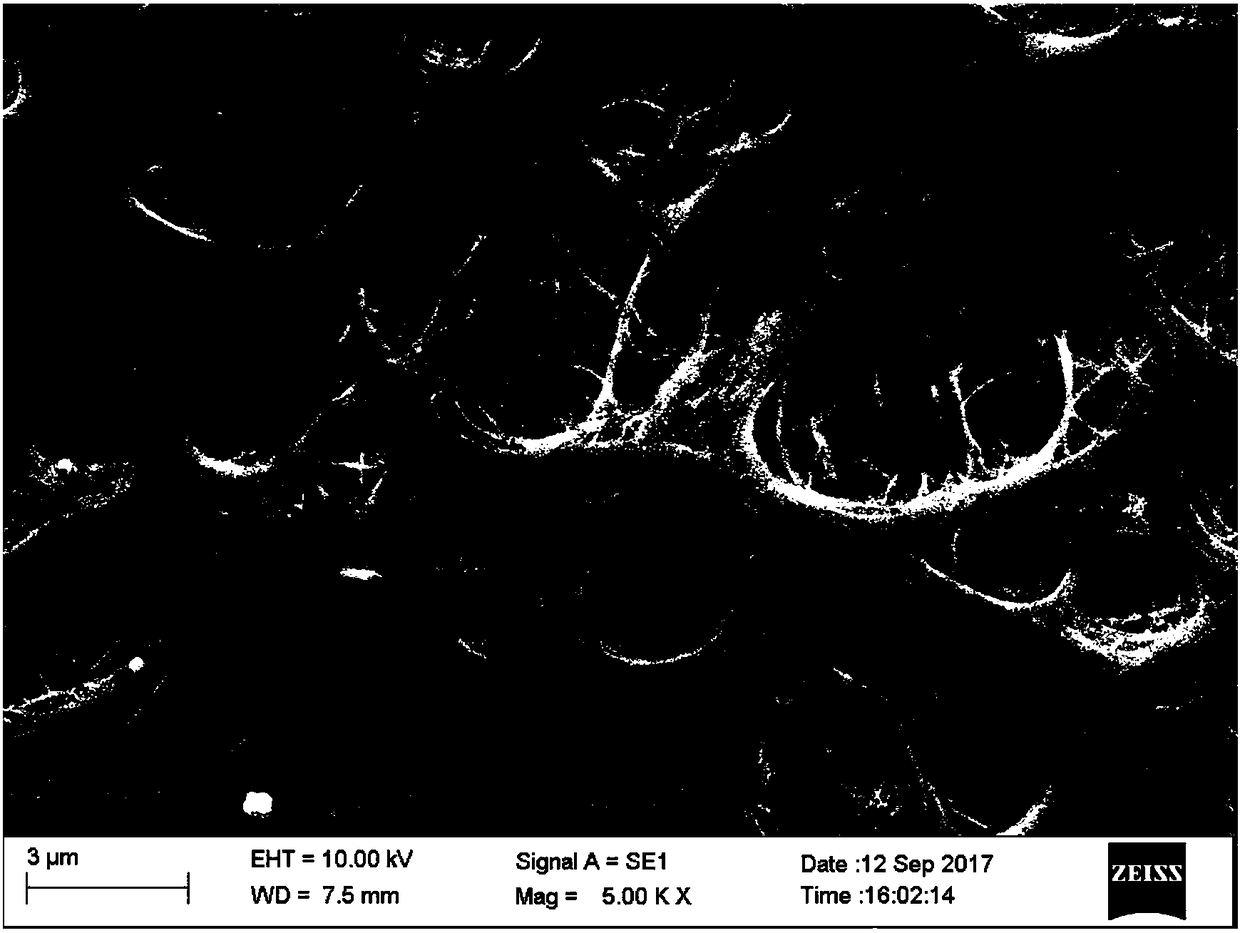

Image

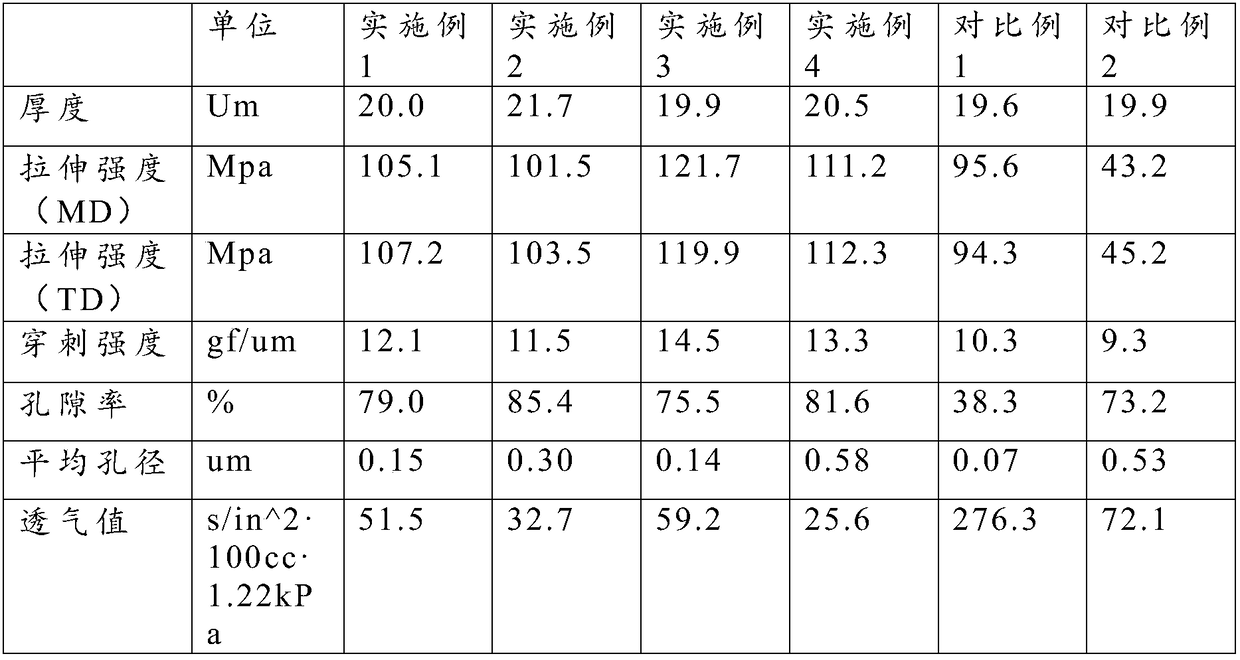

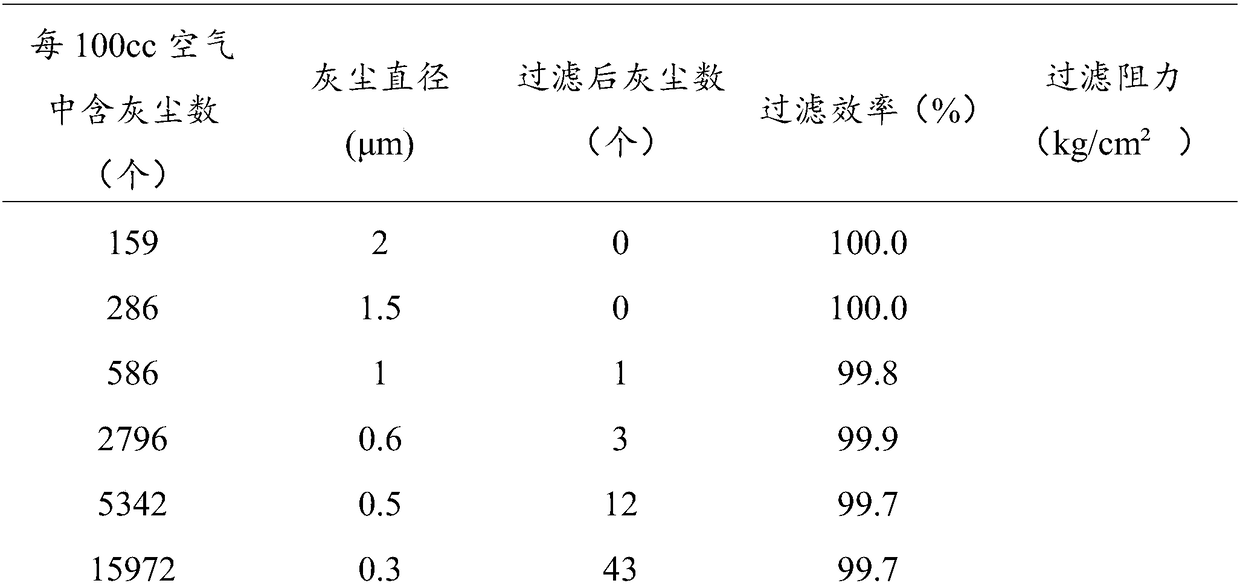

Examples

preparation example Construction

[0026] The embodiment of the present invention provides a method for preparing a high-strength polyethylene microporous membrane, comprising the following steps:

[0027] S1: The polyethylene B and the reaction solvent are mixed in proportion and injected into the reaction vessel for high temperature swelling.

[0028] S2: The polyethylene A and the mixed solution after high temperature swelling are mixed in proportion and then melted to obtain a high temperature melt. The high temperature melt is filtered and metered, pumped into a flat die, and cooled to obtain an oil-containing cast sheet.

[0029] In this step, the polyethylene and the mixed solvent are mutually dissolved at high temperature to form a homogeneous solution, and then heated to phase separation during the cooling process, so that the components in the obtained oil-containing cast sheet can be evenly distributed.

[0030] S3: preheating the oil-containing cast slab and performing high-temperature bidirectional...

Embodiment 1

[0048] Raw materials: polyethylene A has a viscosity-average molecular weight of 1 million, polyethylene B has a viscosity-average molecular weight of 2.3 million, and the reaction solvent is 50# paraffin oil.

[0049] Mix polyethylene B and paraffin oil at a mass ratio of 1:19 and inject it into the swelling tank for high temperature swelling, then mix polyethylene A and high temperature swollen solution according to the mass ratio of polyethylene A and polyethylene B to the mass ratio of the reaction solvent After mixing 3:7, pour it into twin-screws with a diameter of 120mm and an aspect ratio of 52, and melt at a screw speed of 80r / min to obtain a high-temperature melt with a maximum temperature of 220°C. The high-temperature melt is filtered and metered and then pumped into the In the flat die, it flows out through the slit of the die, and then is cooled and formed by a cooling roll at 30°C to obtain an oil-containing cast sheet;

[0050] Preheat the oil-containing cast s...

Embodiment 2

[0055] Preparation method is the same as implementation 1, the difference is:

[0056] The mass ratio of polyethylene B to paraffin oil is 1:9, and the ratio of the total mass of polyethylene A and polyethylene B to the solvent mass is 1:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com