Fischer-Tropsch synthesis reaction product separation equipment

A technology for separation equipment and reaction products, applied in the field of Fischer-Tropsch synthesis, can solve the problems of increased pressure difference between the inlet and outlet of materials in separation equipment, clogging of internal parts, production impact in subsequent sections, etc. Maintain and ensure the effect required by production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

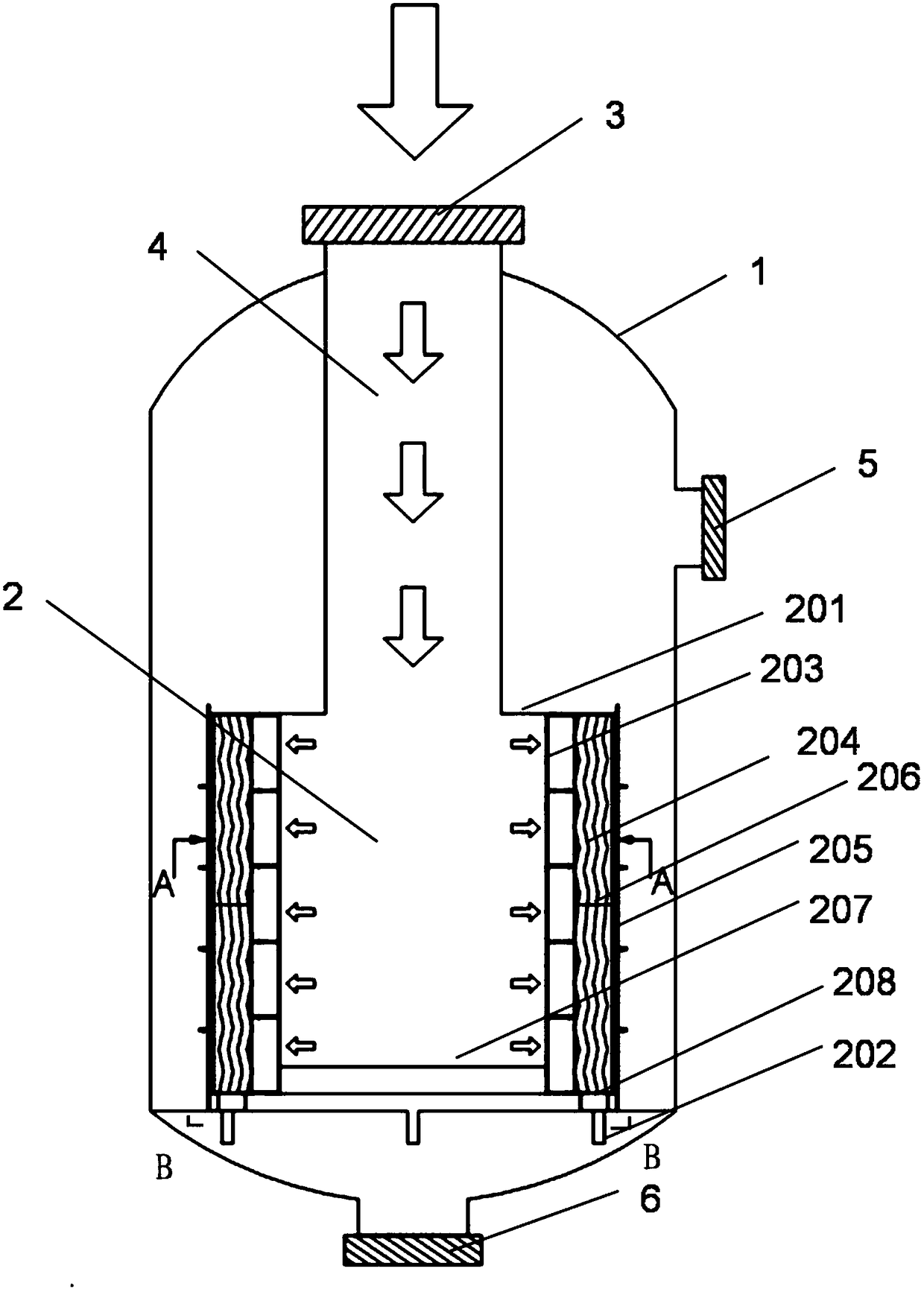

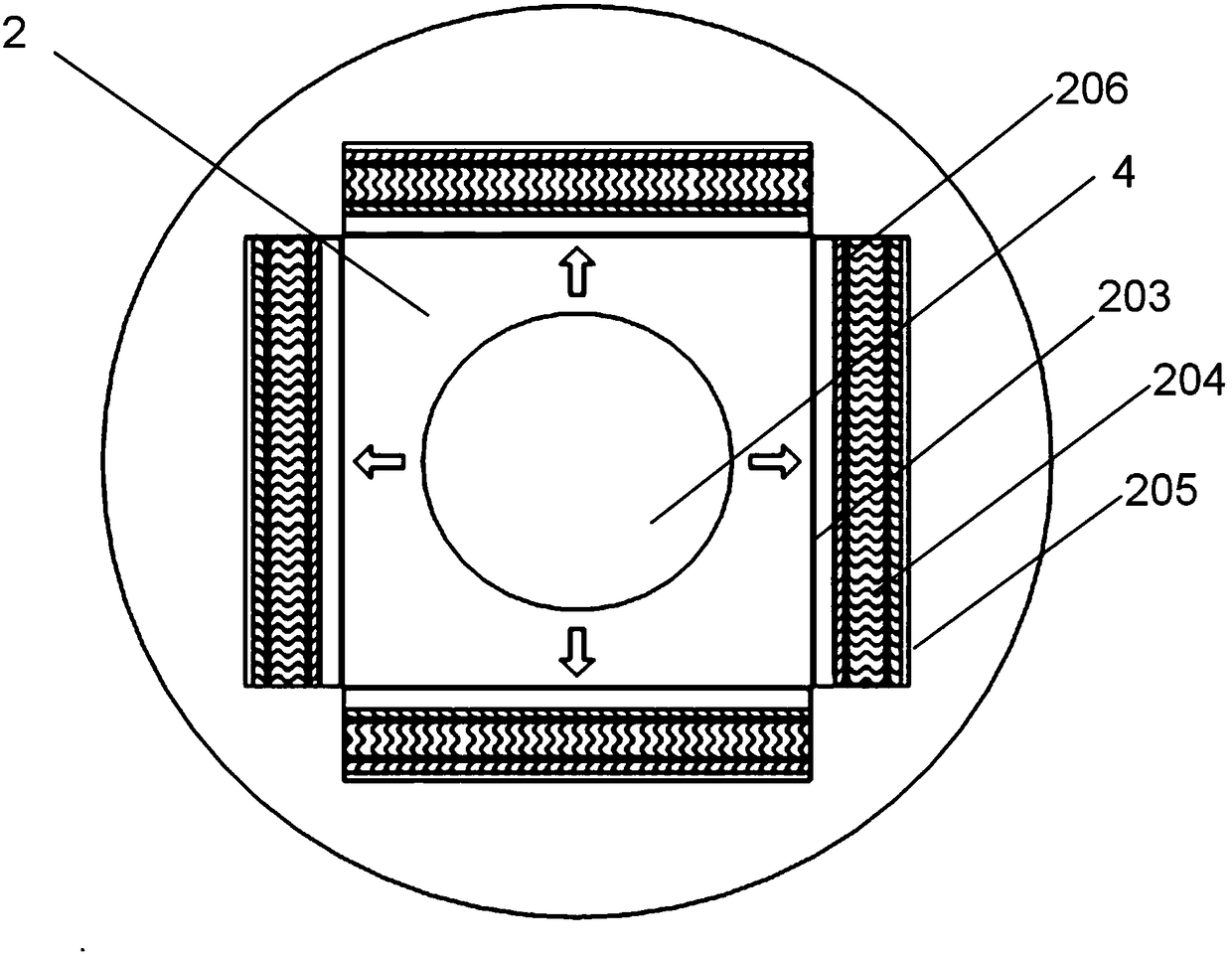

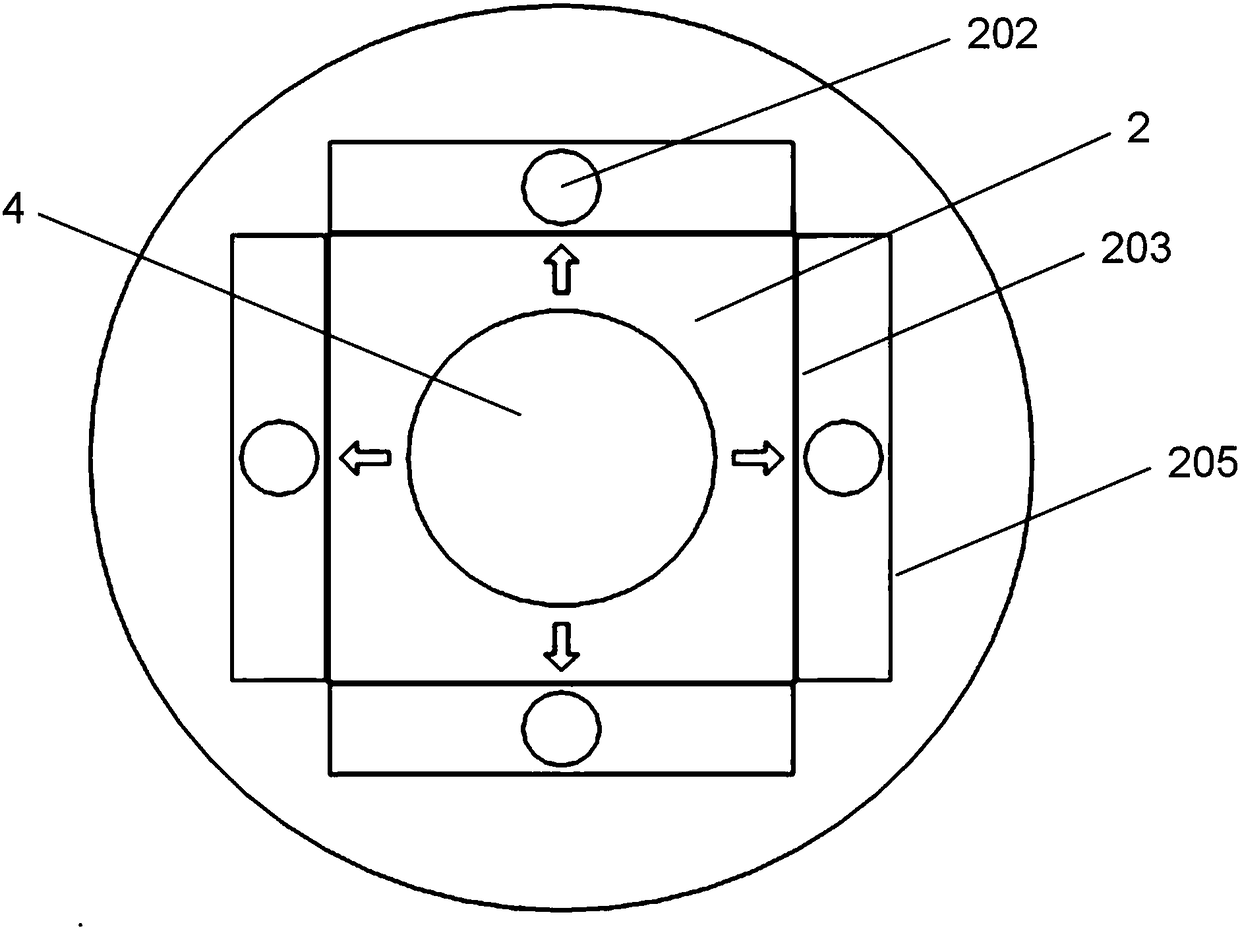

[0038]In one embodiment of the present invention, the separator 2 is composed of 4 filtration separation units. After the Fischer-Tropsch synthesis reaction synthesis gas is cooled by the condenser, the gas-liquid mixture and the entrained catalyst enter the feed port 3 and gradually enter the center cavity of the separator through the feed pipe 4 and fall on the bottom plate 207 . The gas phase components entraining heavy component liquid droplets, catalyst fine powder and water vapor flow to the surroundings in the center cavity of the separator 2, enter the baffle plate group 204 through the inner layer porous plate 203, and in the baffle plate group 204, the gas phase components Flowing in the gap of the plate group, the heavy component liquid droplets entrained with the catalyst fine powder encounter the baffle plate, condense on the plate to form droplets, flow downward on the plate into the filter disc 208, and enter the separation through the downcomer 202 The bottom o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com