Shoe mold core numerical control cutting machine

A cutting machine and mold core technology, which is applied in the direction of automatic control devices, metal sawing equipment, metal processing machinery parts, etc., can solve problems such as uneven distribution of glue, increased processing costs, and consumption of manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

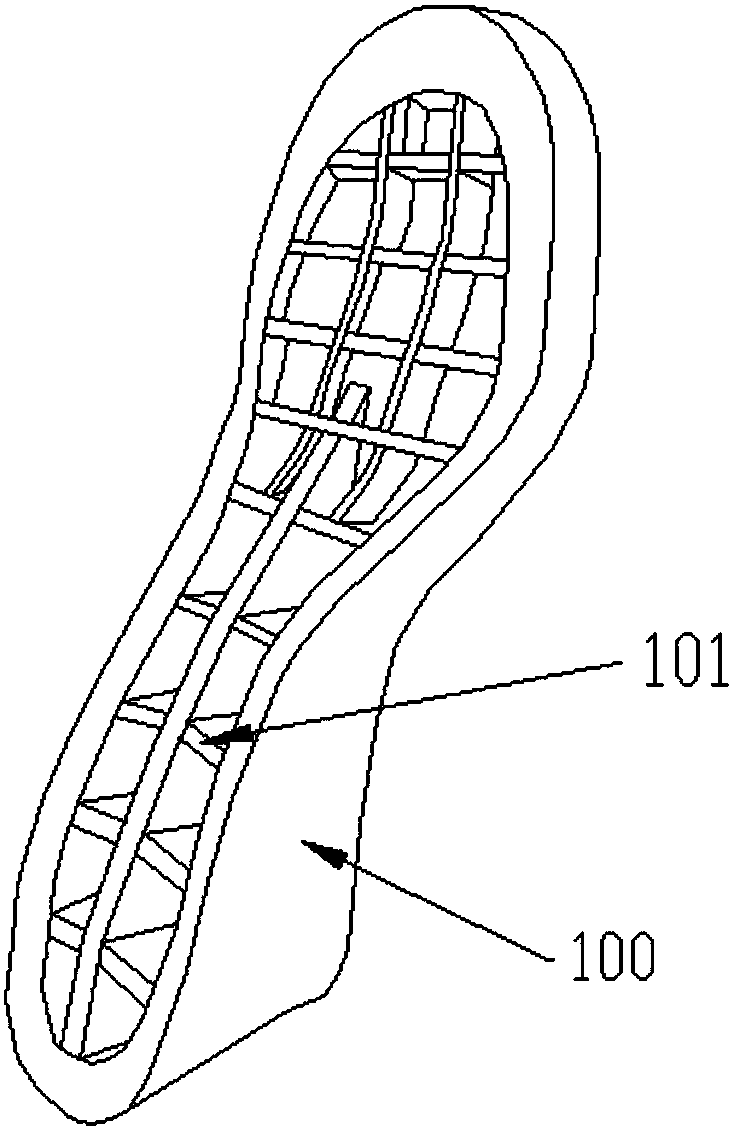

[0121] Such as figure 1 As mentioned in 10, the manufacturing of the mold core and the entire sole keel of the shoe sole of this shape can be cut by this equipment. Compared with the engraving machine processing, this equipment saves man-hours and improves the processing efficiency.

Embodiment 2

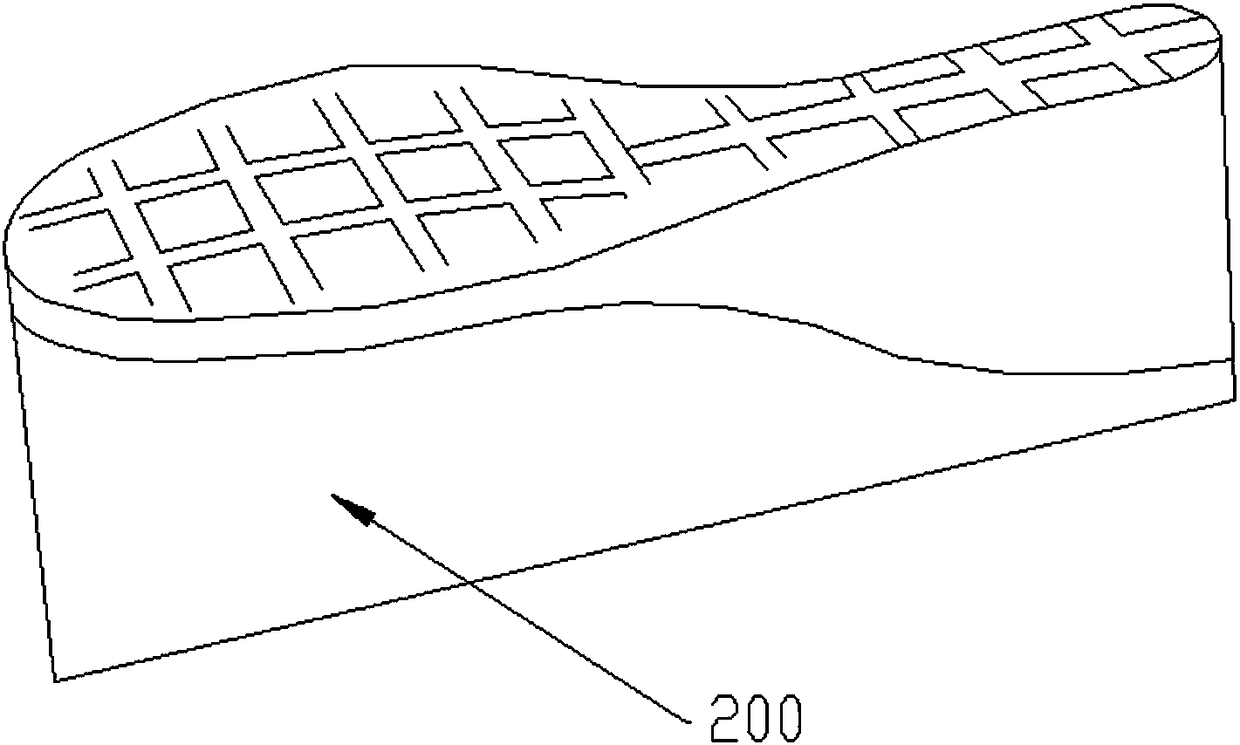

[0123] Such as Figure 5-11 As mentioned, the mold core of the shoe sole of this shape can be manufactured by cutting the keel 101 of the heel part with this equipment, and then the second keel 101-1 of the forefoot part is manufactured by an engraving machine. This arrangement will save more man-hours. Improve processing efficiency.

Embodiment 3

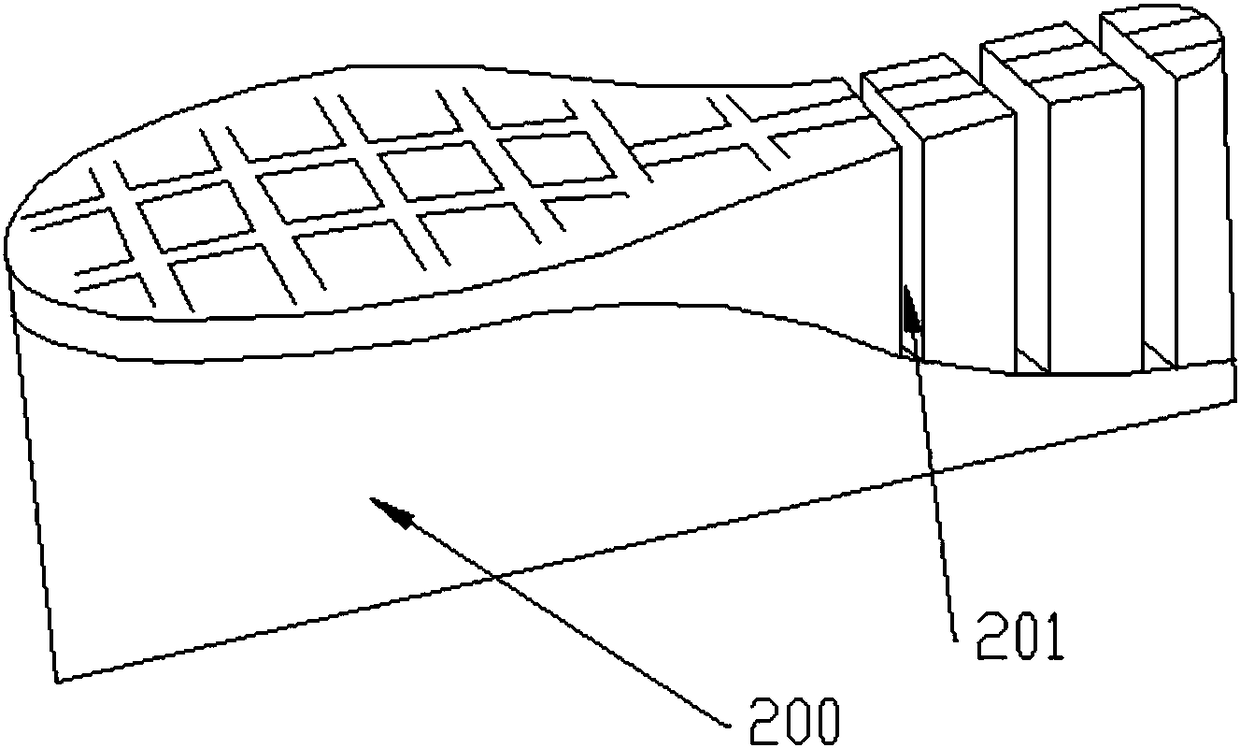

[0125] Such as Figure 5-10 , Picture 12 The keel with symmetrical left and right arcs corresponds to the processing schematic diagram of the shoe mold. The path taken by the circular saw blade is drawn by the dotted line and ends with one cut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com