Asphalt pavement crack pouring material

A technology for grouting material and asphalt pavement, which is used in building thermal insulation materials, building components, buildings, etc., can solve problems such as asphalt aging, and achieve the effects of low price, superior microwave heating capacity, and a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment provides a composition of environment-friendly asphalt pavement joint filling material, which is composed of the following raw materials in terms of mass percentage: base asphalt: 65%, rubber powder: 8%, red brick powder: 2%, trioxide Ferrous powder: 5%, biomass oil: 20%;

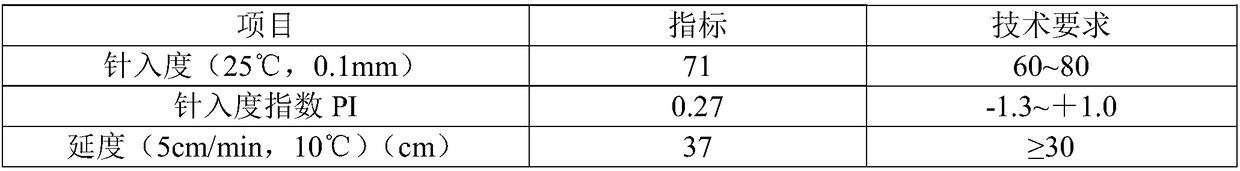

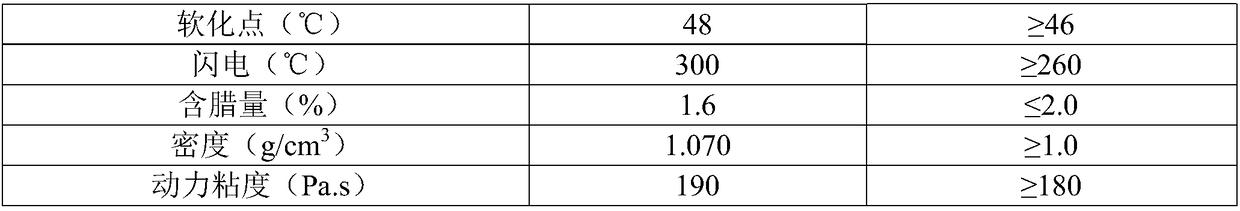

[0022] Asphalt: 70# base asphalt is used, and its technical performance is shown in Table 1.

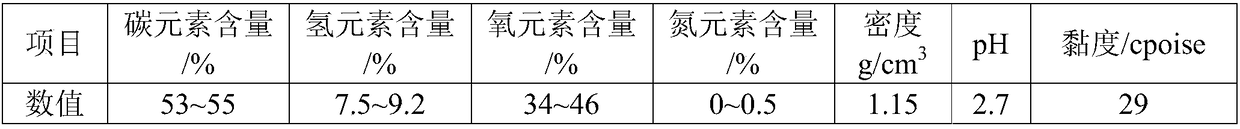

[0023] Biomass oil: Biomass oil made from waste food oil, its technical properties are shown in Table 2.

[0024] Rubber powder: the particle diameter of 142.85g is between 0.180mm and 0.360mm, and its carbon black specific gravity is 82%.

[0025] Red brick powder: the particle size is between 0.095mm and 0.100mm, and its Fe 2 o 3 The weight ratio is 5.3%.

[0026] Ferric oxide powder: particle size between 0.075mm and 0.180mm, Fe 2 o 3 The weight ratio is 99.7%.

[0027] Table 1 Technical properties of asphalt

[0028]

[0029]

[0030] Table 2 Technical indicators of biomass...

Embodiment 2~15

[0039] According to the method described in Example 1, the compositions of environment-friendly asphalt pavement joint filling materials in Examples 2-15 were produced, and the raw materials and their mixing ratios are shown in Table 4. In Table 4, Examples 2 to 4 are cases where the wave-absorbing component is only rubber powder; Examples 5 and 6 are cases where the wave-absorbing component is only red brick powder; The wave component is only the case of ferric oxide; Examples 11 to 15 are the cases where the wave-absorbing components are the above three materials used together.

[0040] Table 4 Mixing ratio of environment-friendly asphalt pavement joint filling material composition

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com