Production method of high-temperature-resistant gridding cloth

A production method and technology of mesh cloth, which is applied in the field of fabrics, can solve the problems of no production method and cumbersome production of mesh cloth, and achieve the effects of shortening the stirring time, good stirring effect and increasing the stirring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

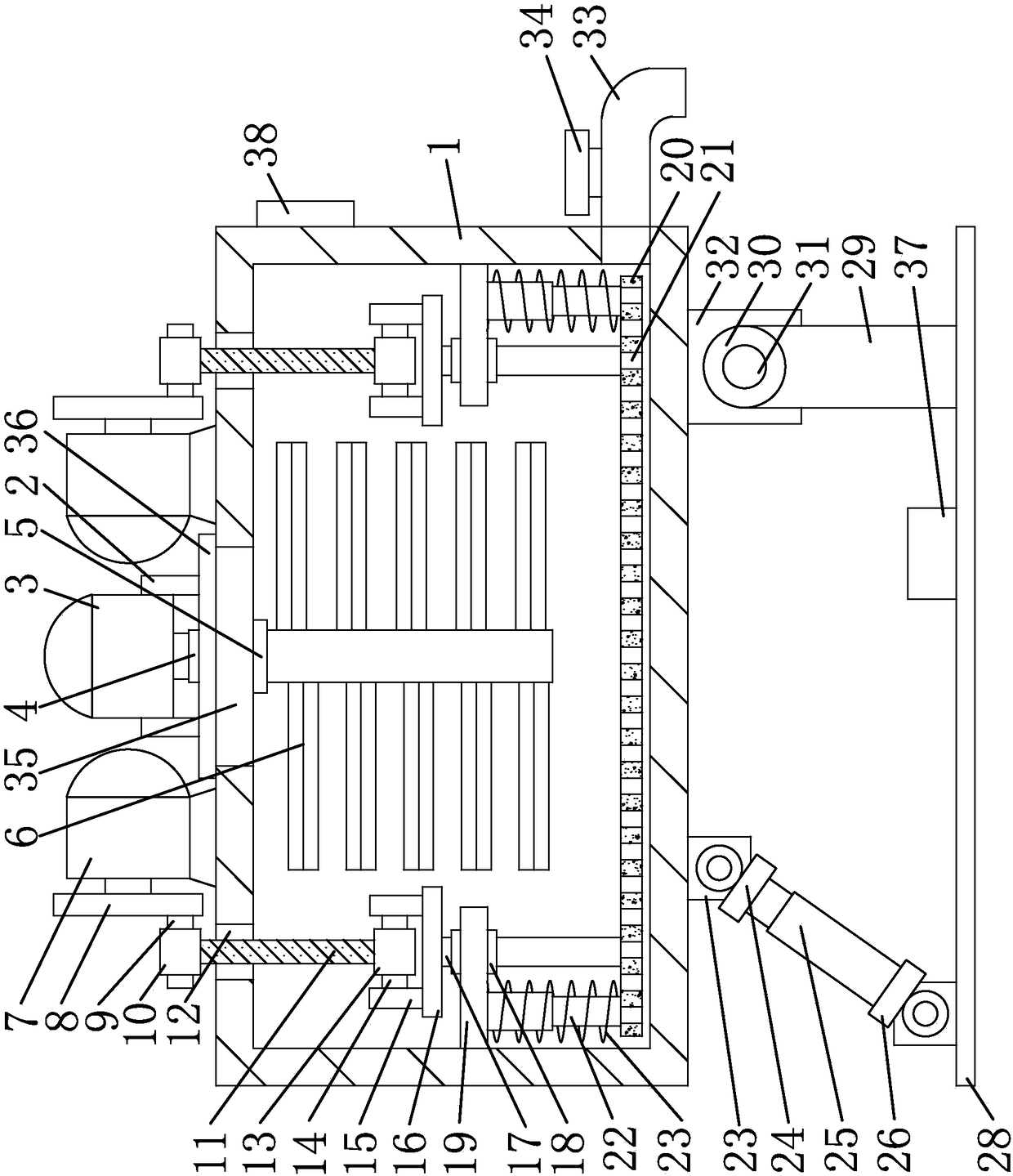

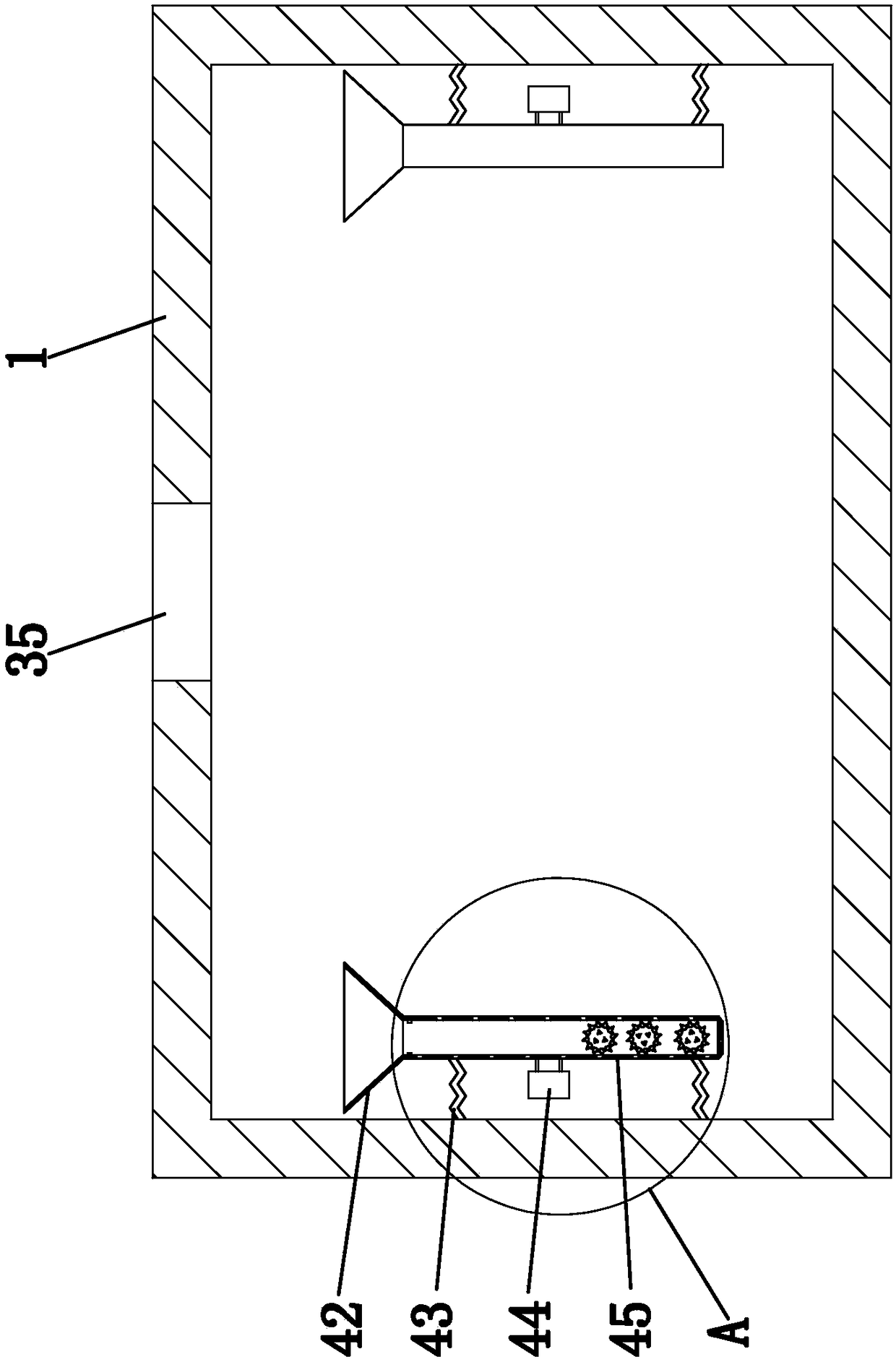

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0035] The production method of the high temperature resistant grid cloth comprises the following steps:

[0036] a, bamboo fiber is woven into grid cloth;

[0037] b. By weight percentage, weigh 15-25% polytetrafluoroethylene, 1-6% crosslinking agent, 4.2-6.8% anhydrous additive, 2-4% catalyst and 50-70% water ; In the present embodiment, take by weighing 22% polytetrafluoroethylene, 4% cross-linking agent, 5% anhydrous additive, 3% catalyst and 66% water; available commercially available adjuvants;

[0038] c. Pour the ingredients in step a into the stirring system for stirring, and the stirring time is 24-36min to prepare the coating liquid; in this embodiment, pour the ingredients in step a into the stirring system f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com