A plant-type monomer solid-based ecological revetment system

A solid foundation and ecological technology, applied in the direction of quay walls, piers, embankments, etc., can solve the problems of maintaining a large amount of manpower and material resources, deterioration of ecological self-healing ability, and uncontrollability, so as to speed up the biochemical reaction rate, facilitate adsorption and Effects of degradation and transfer efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

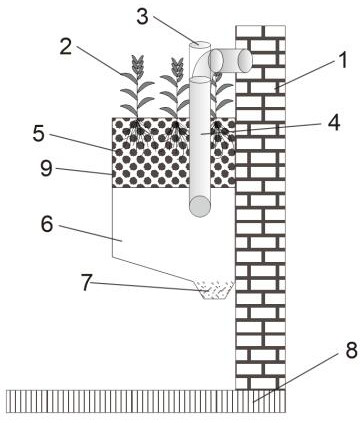

[0039] Set up a plant-based single solid-based ecological revetment system in areas with scattered sewage outlets and limited space, including at least one such as figure 1 As shown in the ecological revetment unit, each ecological revetment unit includes a primary settling reaction zone 6, a solid base carrier zone 9 and a wet plant 2, and the primary settling reaction zone 6 is connected to the bottom of the solid base carrier zone 9. ,

[0040] The primary sedimentation reaction zone 6 includes a water inlet cavity, a water inlet pipe 4 and an emptying pipe 3 that communicate with the solid base carrier zone 9. The water inlet pipe 4 includes a distal end and a proximal end, and the distal end is connected to the urban drainage. pipe connection, the proximal end is arranged in the water inlet cavity, the upper end of the venting pipe 3 is connected to the atmosphere and is higher than the urban drainage pipe, and the lower end of the venting pipe 3 is connected to the water...

Embodiment 2

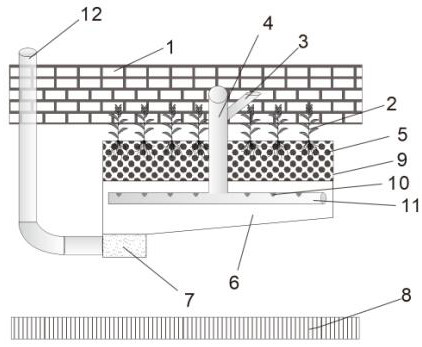

[0057] Set up a plant-based single solid-based ecological revetment system in areas with scattered sewage outlets and limited space, including at least one such as figure 2 As shown in the ecological revetment unit, each ecological revetment unit includes a primary settling reaction zone 6, a solid base carrier zone 9 and a wet plant 2, and the primary settling reaction zone 6 is connected to the bottom of the solid base carrier zone 9. ,

[0058] The primary sedimentation reaction zone 6 includes a water inlet cavity, a water inlet pipe 4 and an emptying pipe 3 that communicate with the solid base carrier zone 9. The water inlet pipe 4 includes a distal end and a proximal end, and the distal end is connected to the urban drainage. pipe connection, the proximal end is arranged in the water inlet cavity, the upper end of the venting pipe 3 is connected to the atmosphere and is higher than the urban drainage pipe, and the lower end of the venting pipe 3 is connected to the wate...

Embodiment 3

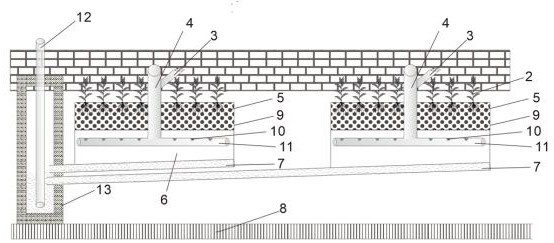

[0074] Set up plant-based single solid-based ecological revetment systems in areas with concentrated sewage outlets, heavy pollution and long pollution zones, including at least one such as image 3 The ecological revetment unit shown, image 3 Two of the ecological revetment units are shown in , each of the ecological revetment units includes a primary sedimentation reaction zone 6, a solid base carrier zone 9 and a wet plant 2, and the primary sedimentation reaction zone 6 is connected to the solid base carrier. below zone 9,

[0075] The primary sedimentation reaction zone 6 includes a water inlet cavity, a water inlet pipe 4 and an emptying pipe 3 that communicate with the solid base carrier zone 9. The water inlet pipe 4 includes a distal end and a proximal end, and the distal end is connected to the urban drainage. pipe connection, the proximal end is arranged in the water inlet cavity, the upper end of the venting pipe 3 is connected to the atmosphere and is higher tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com