Energy source horizontal warehouse system

A bungalow and energy technology, applied in the field of grain storage, can solve the problems of high construction cost and difficulty, long storage time, etc., and achieve the effect of reducing construction cost and difficulty, large grain loading, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

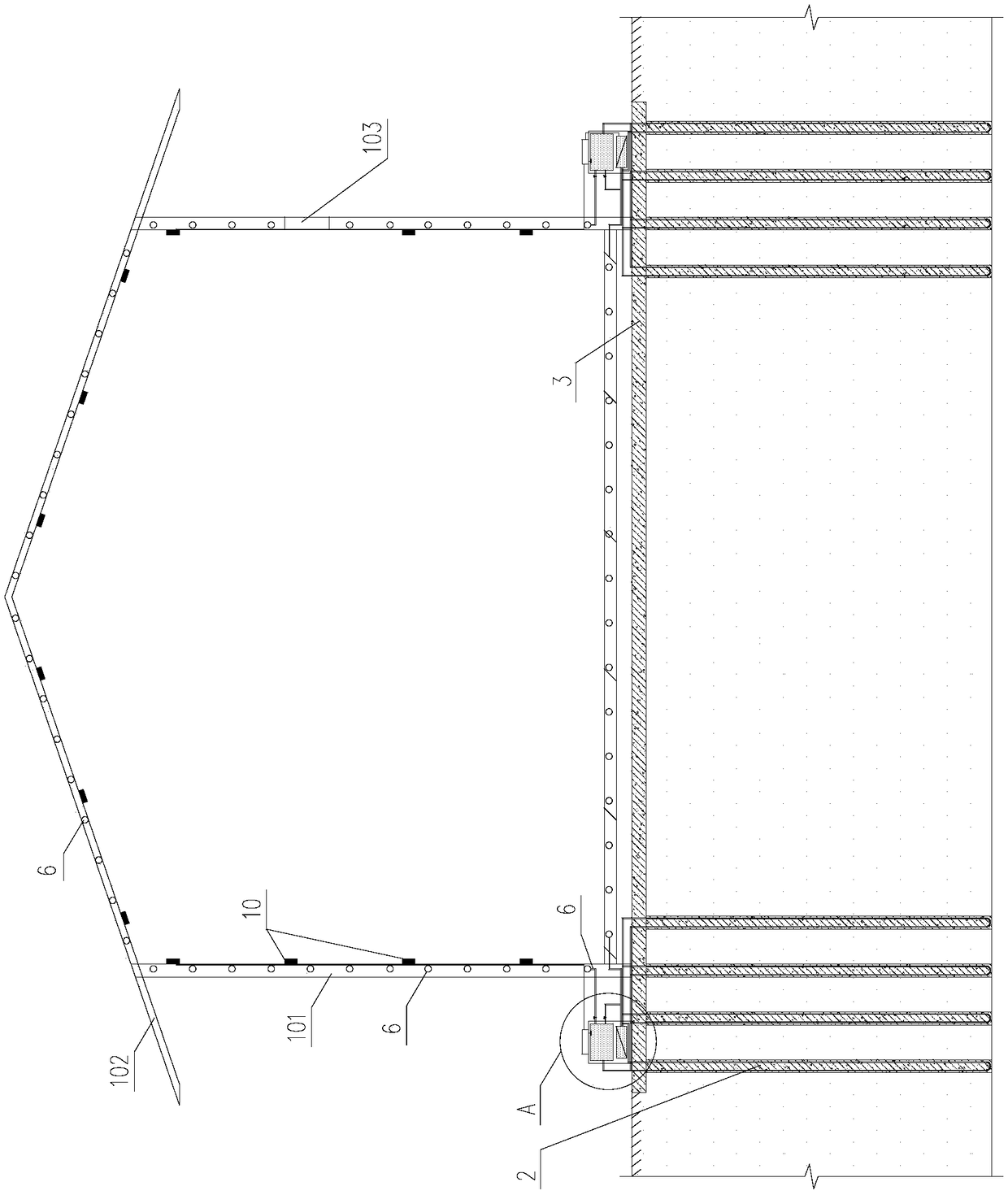

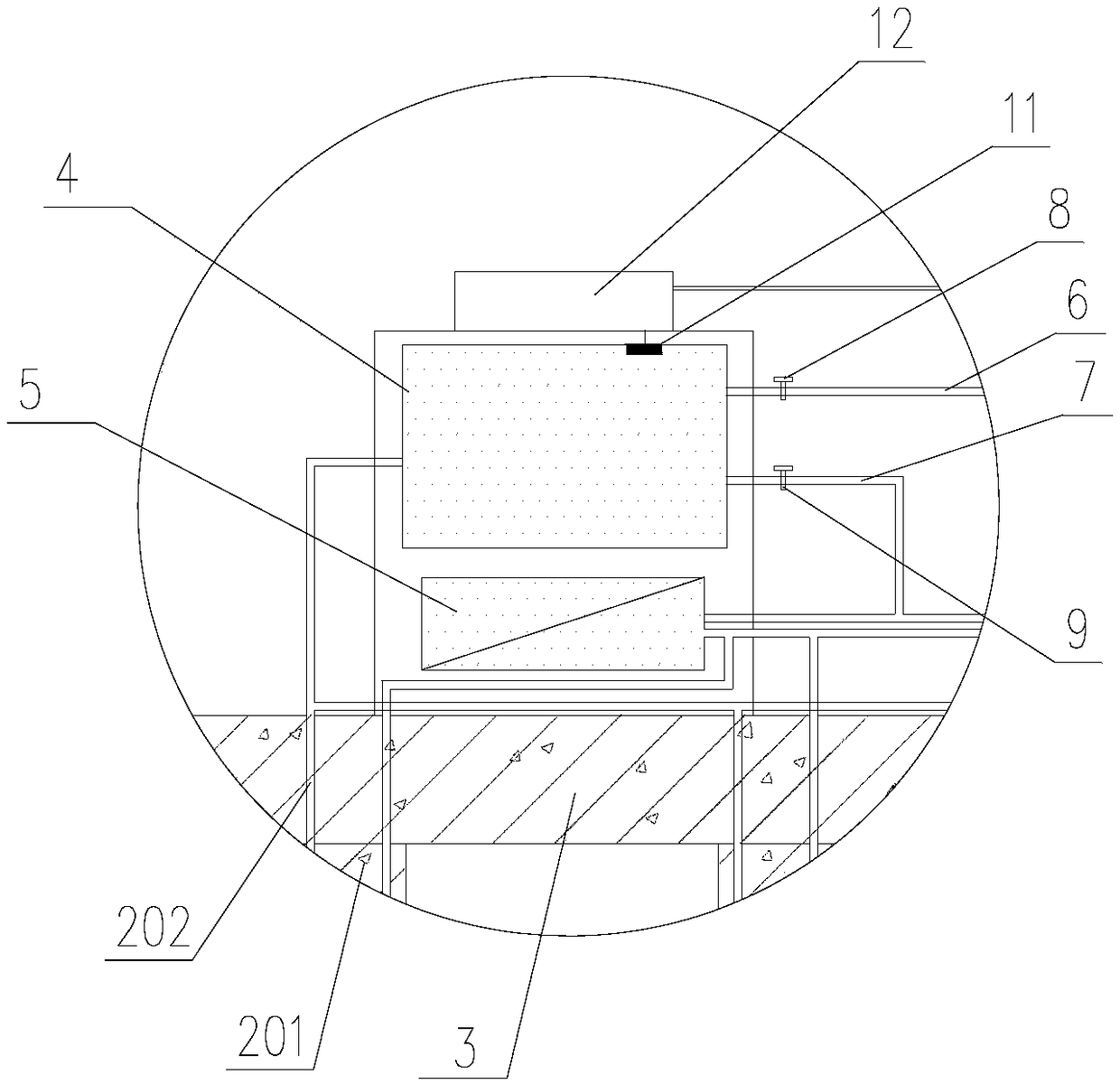

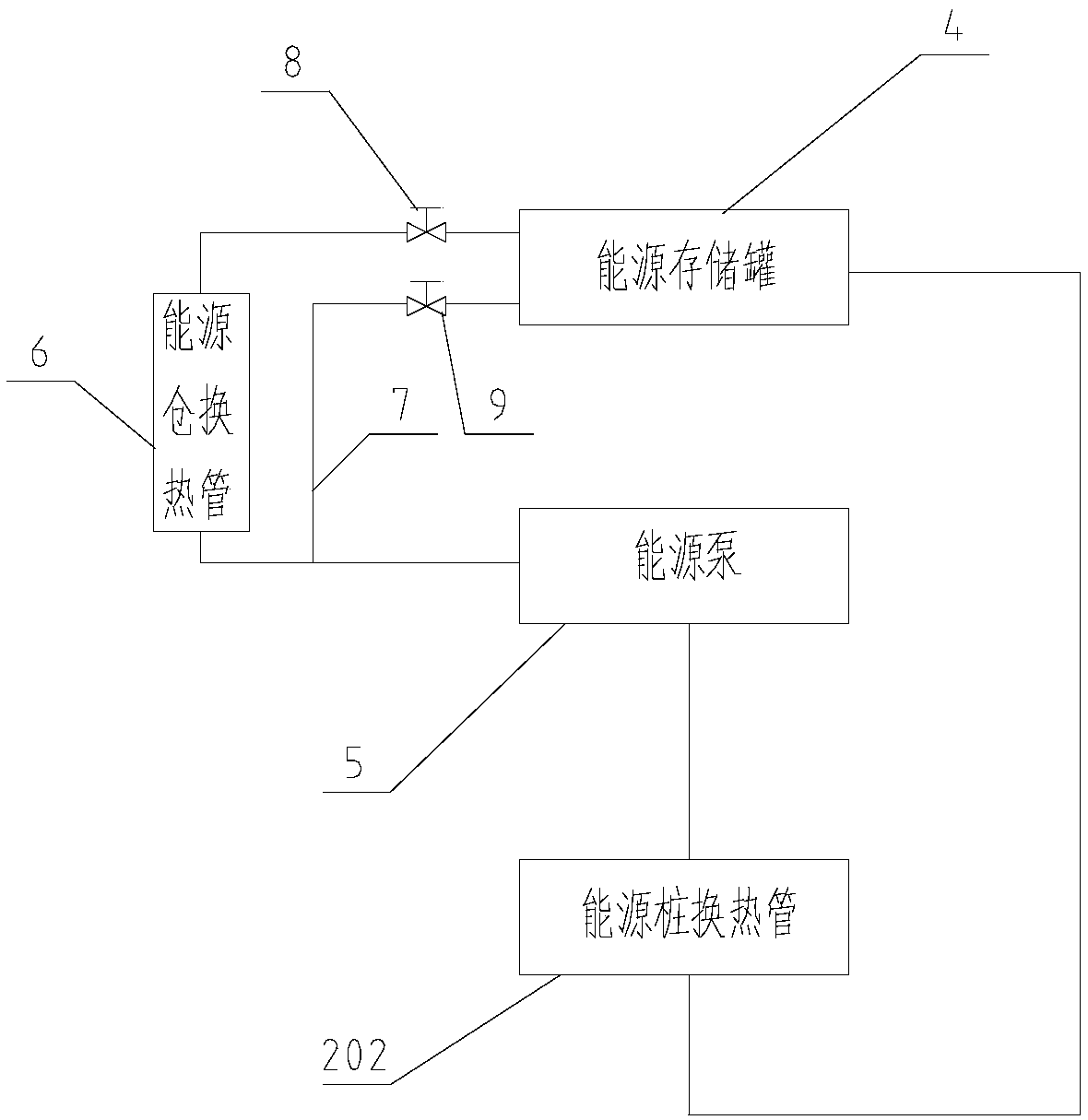

[0028] Such as Figure 1 to Figure 6 As shown, an energy flat warehouse system of the present invention includes a flat warehouse. The flat warehouse includes a warehouse body 101 and a warehouse roof 102. The warehouse roof 102 is a gable roof or a round roof. The warehouse body 101 is surrounded by four walls. The bottom of 101 is a flat bottom, the upper side of the warehouse body 101 is provided with vents 103, the bottom of the bungalow warehouse is a pile foundation, the bungalow warehouse is supported on the pile foundation, and the outer surface of the bungalow warehouse roof 102 is coated with heat-reflective heat-insulating paint. The pile foundation includes an energy pile 2 and a cap 3 fixedly connected to the top of the energy pile 2. The energy pile 2 includes a pile body 201 and an energy pile heat exchange tube 202. The pile body 201 is buried in the soil below the surface, and the energy pile heat exchange tube 202 The pipe 202 is arranged inside the pile body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com