Radial grouting construction method of one-hole dual-pipe tunnel

A construction method and grouting technology, applied in tunnels, tunnel linings, earth-moving drilling, etc., can solve the problems of poor orifice sealing, leakage of grouting, poor grouting effect, etc. The effect of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

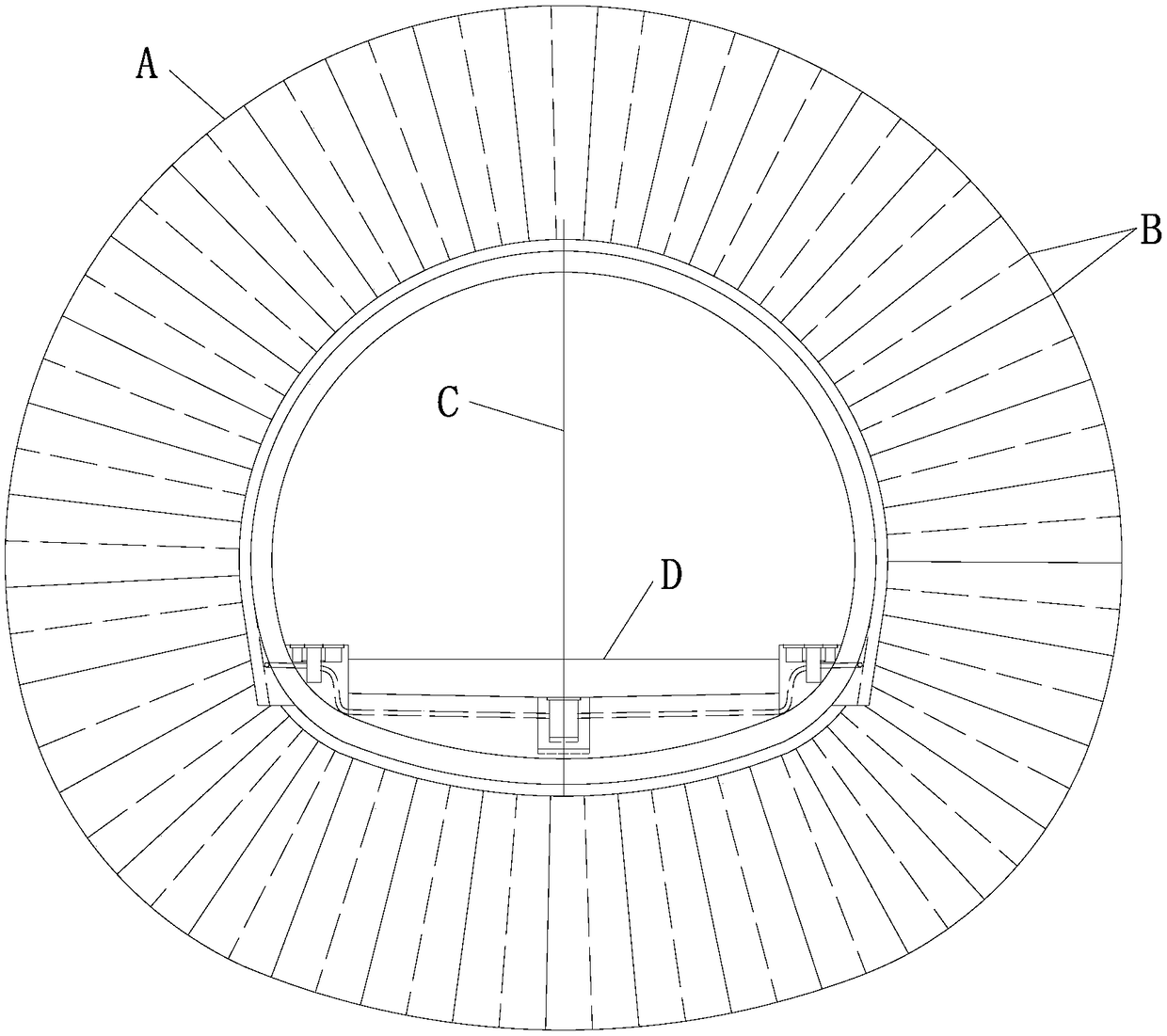

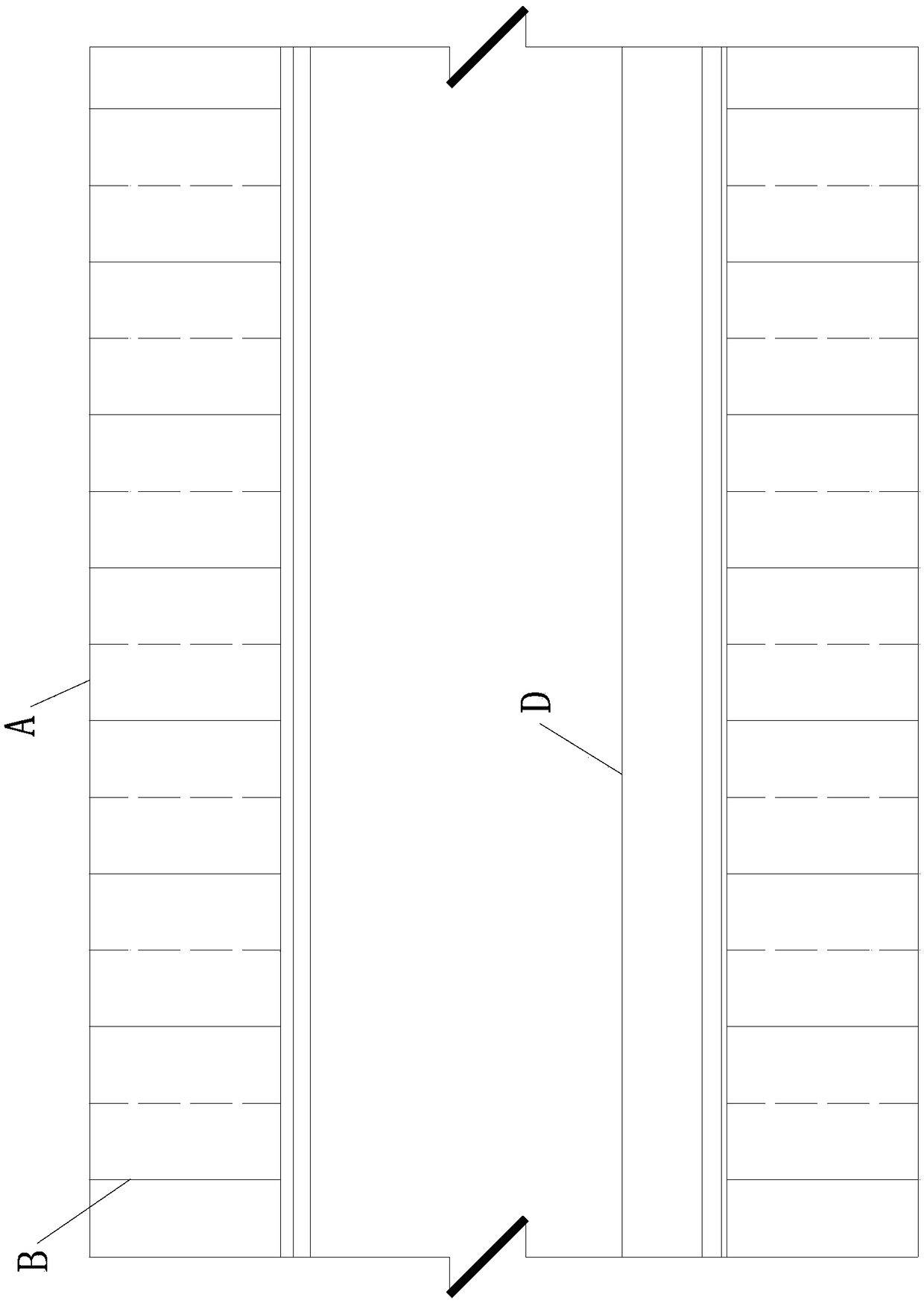

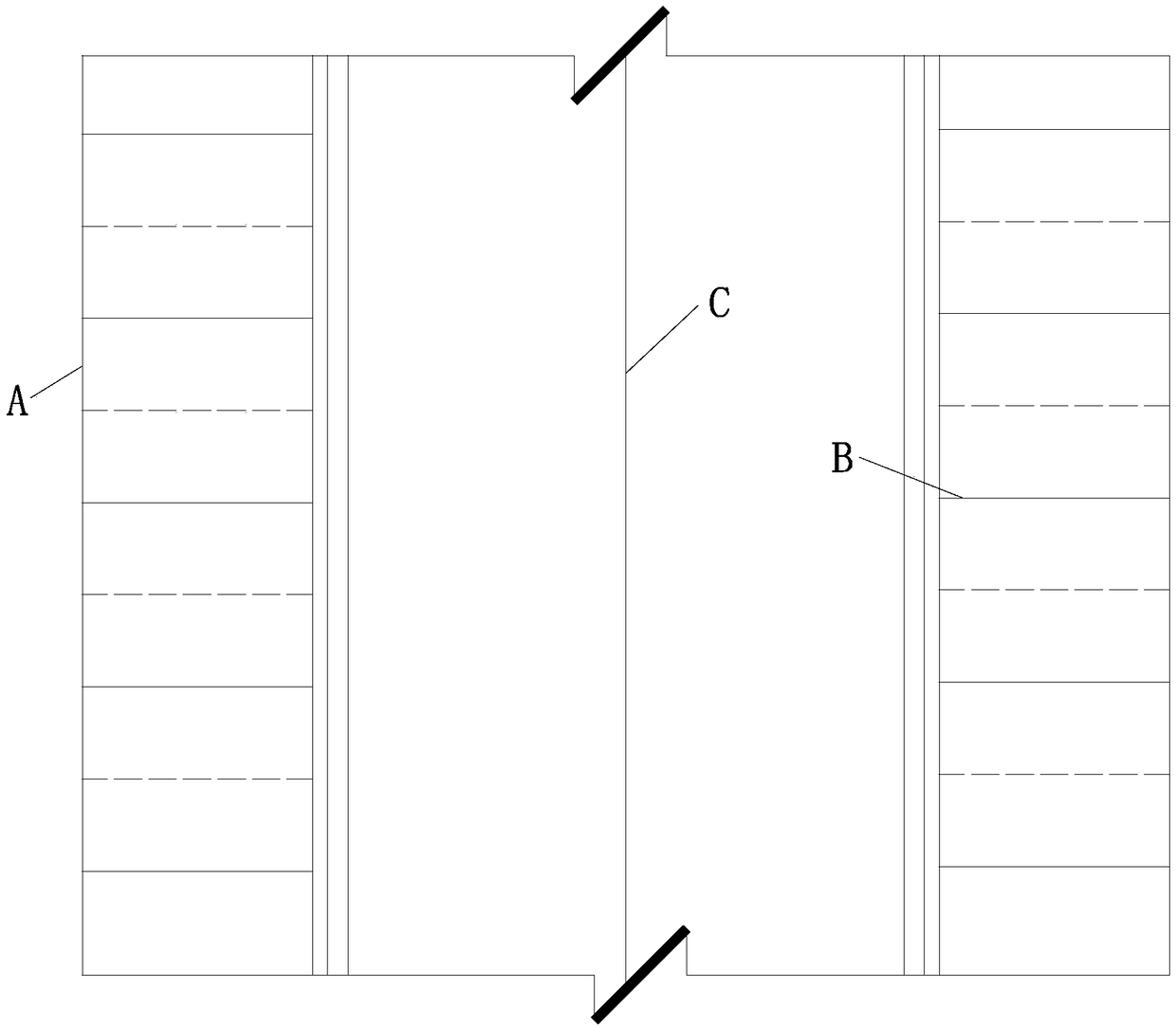

[0030] see Figure 1-Figure 7 Description, a radial grouting construction method for a one-hole double-pipe tunnel, the method is carried out according to the following steps:

[0031] Step 1. Drilling. The bottom of the tunnel is drilled with a down-the-hole machine. After the initial support of the inverted arch at the bottom of the tunnel is completed, the holes are laid out. The side walls and arches are drilled with a drill bit air gun. After the drilling is completed, they are washed with high-pressure water. no debris;

[0032] Step 2. Install the grouting pipe. The grouting pipe 1 is a high-pressure pipe, and two are buried. One grouting pipe 1 is arranged in a full hole. A grouting pipe head of a certain length is reserved for the orifice, and a plum blossom hole of a certain diameter is opened on the pipe body. , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com