Waterproof treatment process of strain gauge on guide tube of underwater fuel assembly

A technology for waterproof treatment and fuel assembly, which is applied in the assembly of fuel elements, greenhouse gas reduction, climate sustainability, etc. The effect of water scouring and falling off, fast forming speed and small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

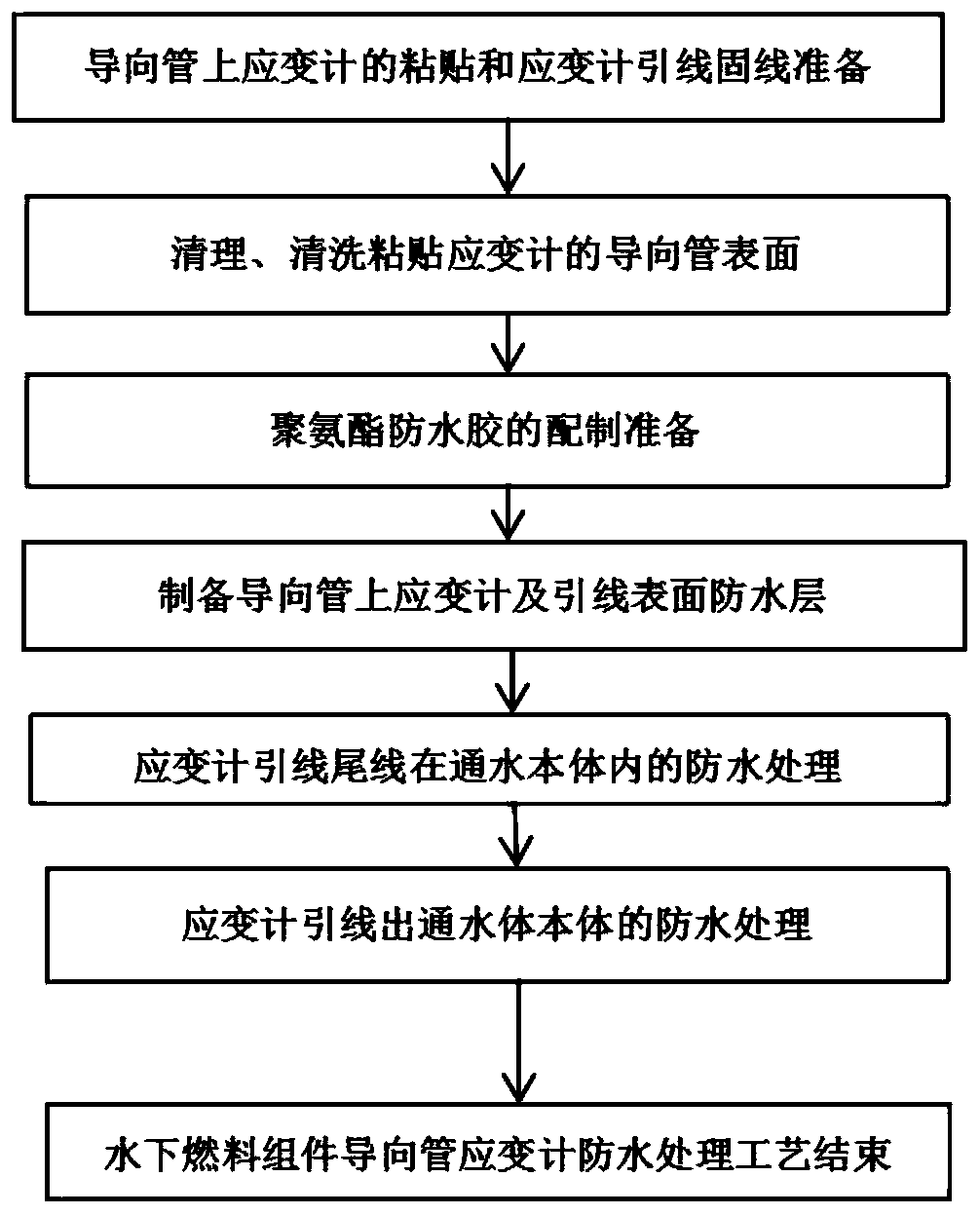

[0039] Such as figure 1 Shown is the first embodiment of the present invention, the waterproof treatment process of the strain gauge on the guide pipe of the underwater fuel assembly, comprising the following steps:

[0040] 1. Sticking of the strain gauge on the guide tube and preparation of the strain gauge lead wire fixation (in strict accordance with the "Fuel Assembly Strain Gauge On-Site Paste Process Regulations" and "Fuel Assembly Strain Gauge On-site Paste Scheme");

[0041] Include the following steps:

[0042] A1: Detect and number the strain gauges to be pasted one by one;

[0043] A2: Weld and install the inner layer guide tube, and paste the strain gauge on the welded inner layer guide tube;

[0044] A3: Weld and install the outer guide tube, and paste the strain gauge on the welded outer guide tube;

[0045] A4: Weld and install the corner guide tube, and paste the strain gauge on the welded corner guide tube;

[0046] A5: Check the sticking quality of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com