Mechanical arm and semiconductor device

A robotic arm and connecting arm technology, applied in semiconductor/solid state device manufacturing, conveyor objects, electrical components, etc., can solve problems such as wafer offset, robotic arm vibration, wafer collision with production machines, Accurate position and the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the existing robotic arm equipment, the process of using the robotic arm to transfer the wafer usually includes: using the robotic arm to vacuum the wafer from the bottom of the wafer, and then controlling the movement of the robotic arm to carry out send. However, in the prior art, it is easy for the wafer to be shifted on the robot arm, etc., resulting in a wrong placement position of the wafer in the subsequent process, causing serious process problems, and even causing the robot arm to carry Wafers cannot enter the machine, and the robotic arm is deflected or bumped, causing the machine to alarm and stop. Specifically, after the wafer is shifted on the robot arm, the robot arm still moves according to the original route, which may cause the wafer to collide with the production machine, causing the robot arm to vibrate, and in severe cases, the robot arm may be deflected or bumped .

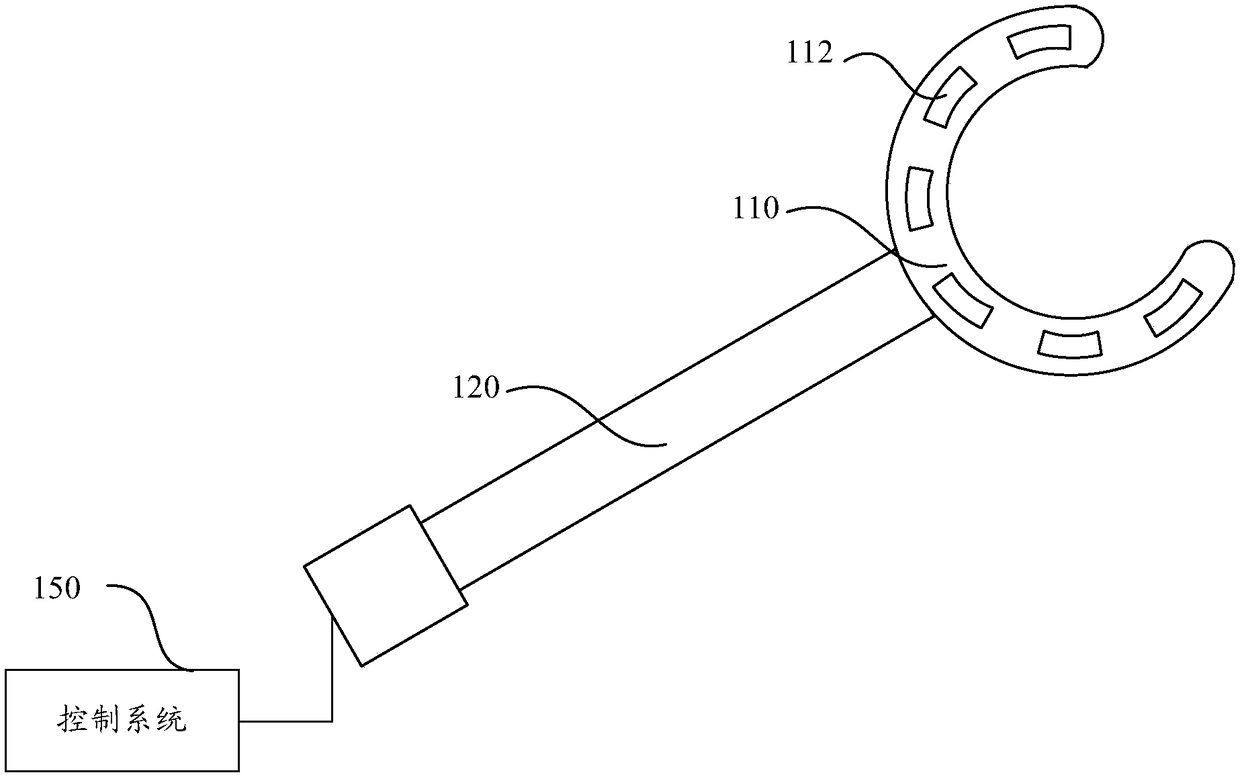

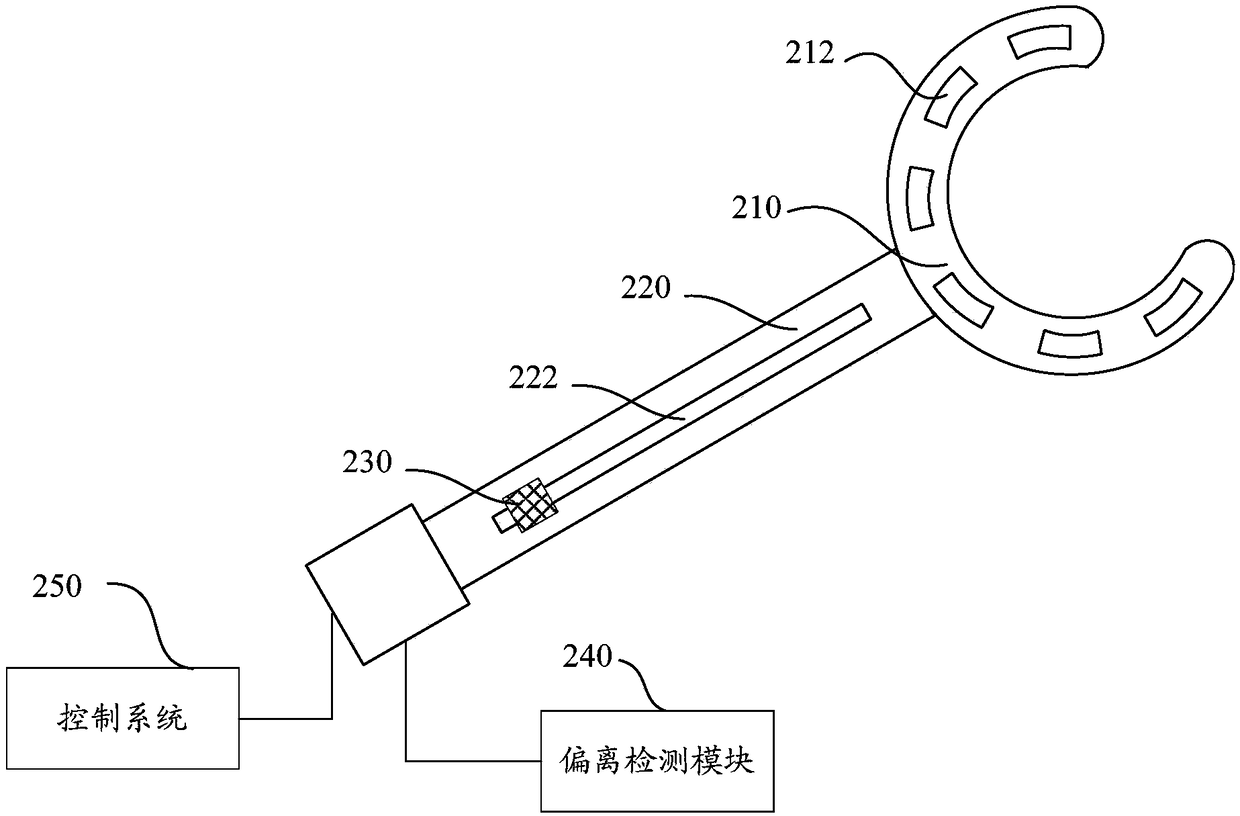

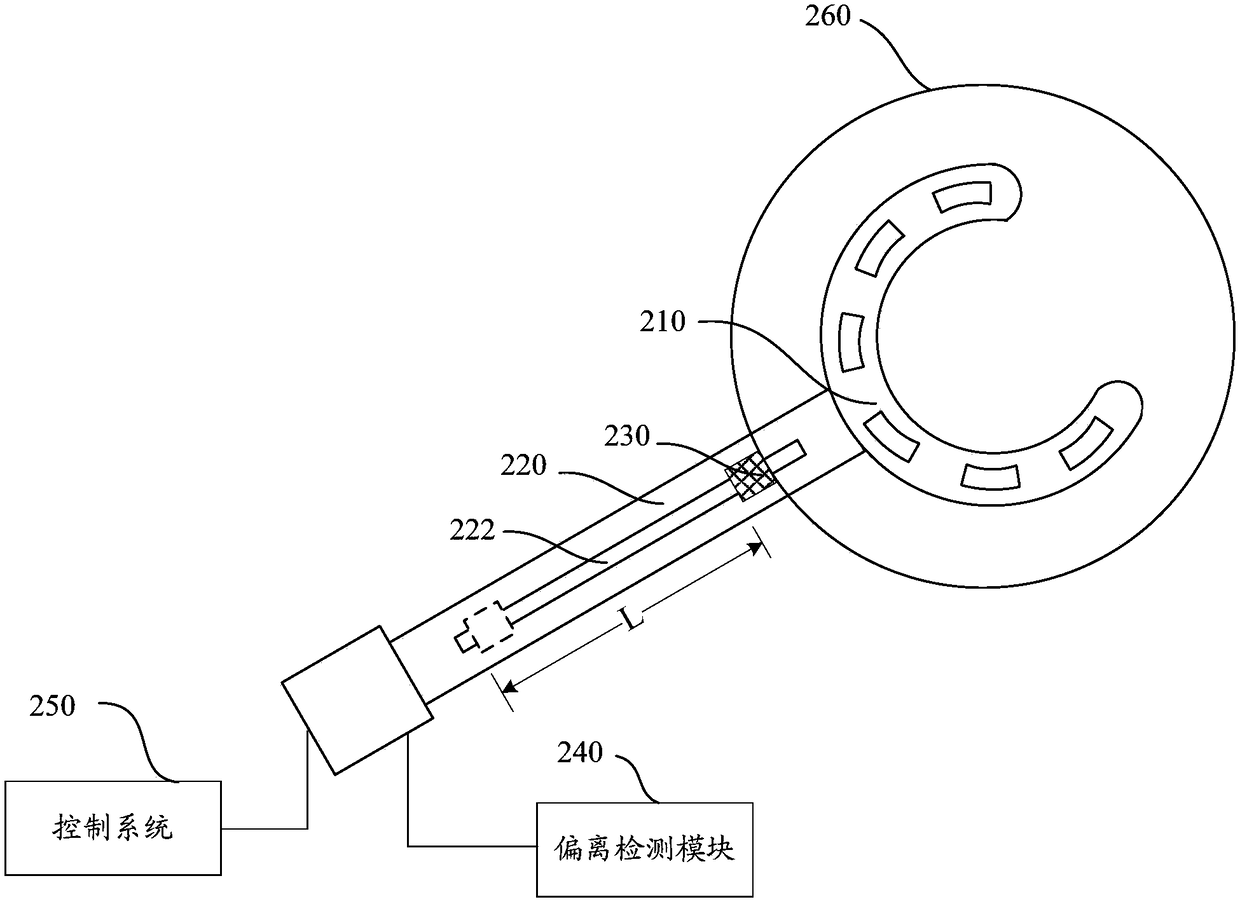

[0031] refer to figure 1 , figure 1 It is a structural schematic diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com