Flexible substrate and manufacturing method thereof, manufacturing method of display panel, and display device

A flexible display and flexible substrate technology, applied in the direction of final product manufacturing, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as difficult stretching or deformation, large elastic modulus of flexible substrates, and fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment aims at the problem that the quality of the flexible substrate affects the performance of the control element TFT and the light-emitting device OLED, and provides a flexible substrate that provides sufficient ductility while ensuring the supporting performance.

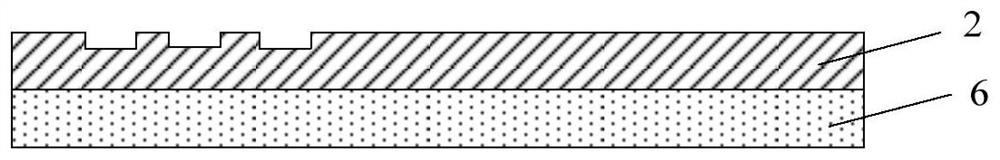

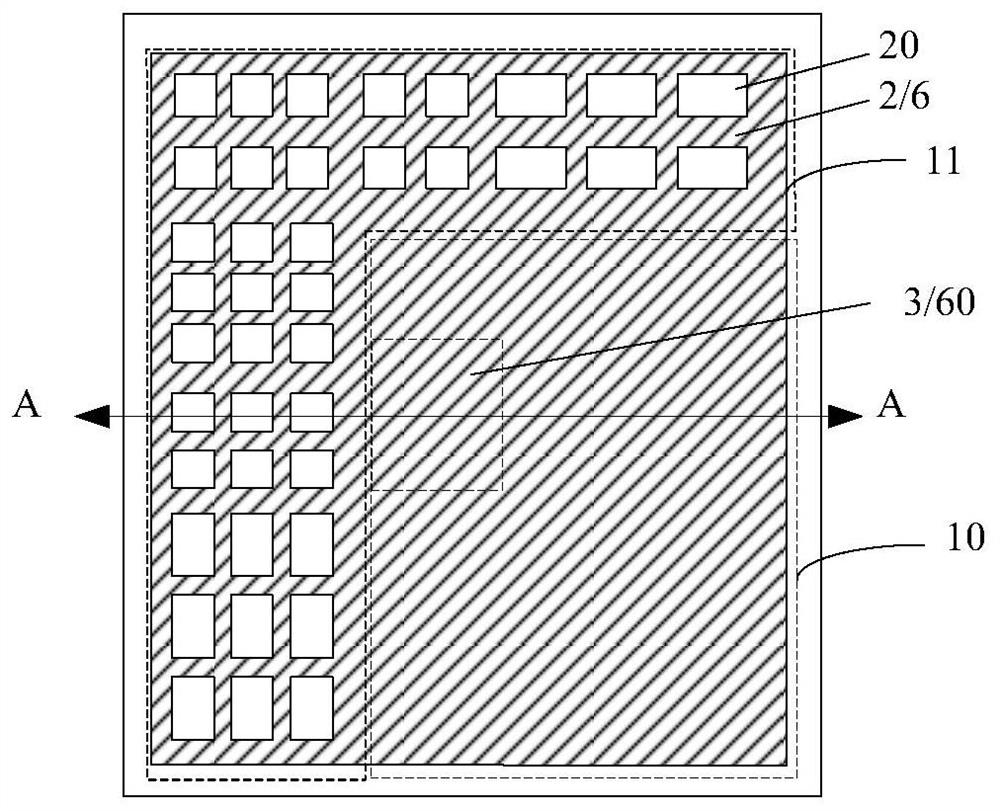

[0053] The flexible substrate is used to carry a flexible display device. The flexible display device is provided with a display area. The display area is divided into a plurality of pixel areas, and there are spacer areas between adjacent pixel areas. The flexible substrate includes a supporting layer, such as figure 1 and figure 2As shown, one surface layer of the support layer 2 is provided with a plurality of micro-grooves 20 in a region corresponding to the spacer region 11 between adjacent pixel regions 10 . When the flexible substrate is used to form a display panel, micro grooves 20 are provided on the side of the support layer 2 where the flexible display device is disposed, that is, t...

Embodiment 2

[0078] This embodiment provides a flexible substrate that provides sufficient ductility while ensuring support performance.

[0079] The flexible display device also includes a non-display area located at the periphery of the display area, and a binding area is provided in the non-display area. The difference from Embodiment 1 is that the flexible substrate is in an area corresponding to the non-display area except the binding area. A plurality of microgrooves 20 are provided.

[0080] Wherein, in the area corresponding to the non-display area except the binding area, a plurality of micro-grooves 20 are evenly distributed; or, the density of the plurality of micro-grooves 20 near the edge is greater than that in the middle, or the density of the plurality of micro-grooves 20 is greater than that in the middle. The groove 20 is larger in size near the edges than in the middle. Under the same stress conditions, the thinner area has better ductility, and the surface area of th...

Embodiment 3

[0084] On the basis of Embodiment 1 and Embodiment 2, this embodiment provides a method for manufacturing a display panel, which makes full use of the above-mentioned flexible substrate to realize the preparation of a flexible display device.

[0085] The above-mentioned flexible substrate becomes a part of the flexible display panel, such as Figure 5A-Figure 5E As shown, the preparation method of the display panel includes:

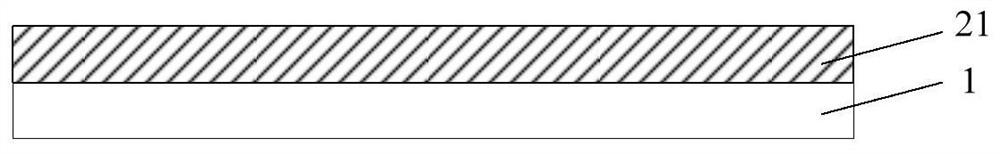

[0086] First, in Figure 5A Among them, the above-mentioned supporting film layer 21 of the flexible substrate is arranged above the substrate pad 1 . That is, the support film layer 21 is set on the substrate liner 1, and the surface layer of the support film layer 21 is patterned (depth ),form Figure 5B The micro-grooves 20 are shown, and the micro-grooves 20 are all over the support layer 2 in the region corresponding to the spacer region 11 .

[0087] Next, a control element is formed on the side of the supporting layer provided with the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com