Molten steel tank edge masonry construction without gland plate and construction method of molten steel tank edge masonry construction

A technology for masonry structures and molten steel tanks. It is applied in the direction of manufacturing tools, metal processing equipment, and casting melt containers. It can solve the problems of not meeting the requirements of use, difficult control of construction quality, and poor gland effect, etc. problems, to achieve good construction quality, control construction quality, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

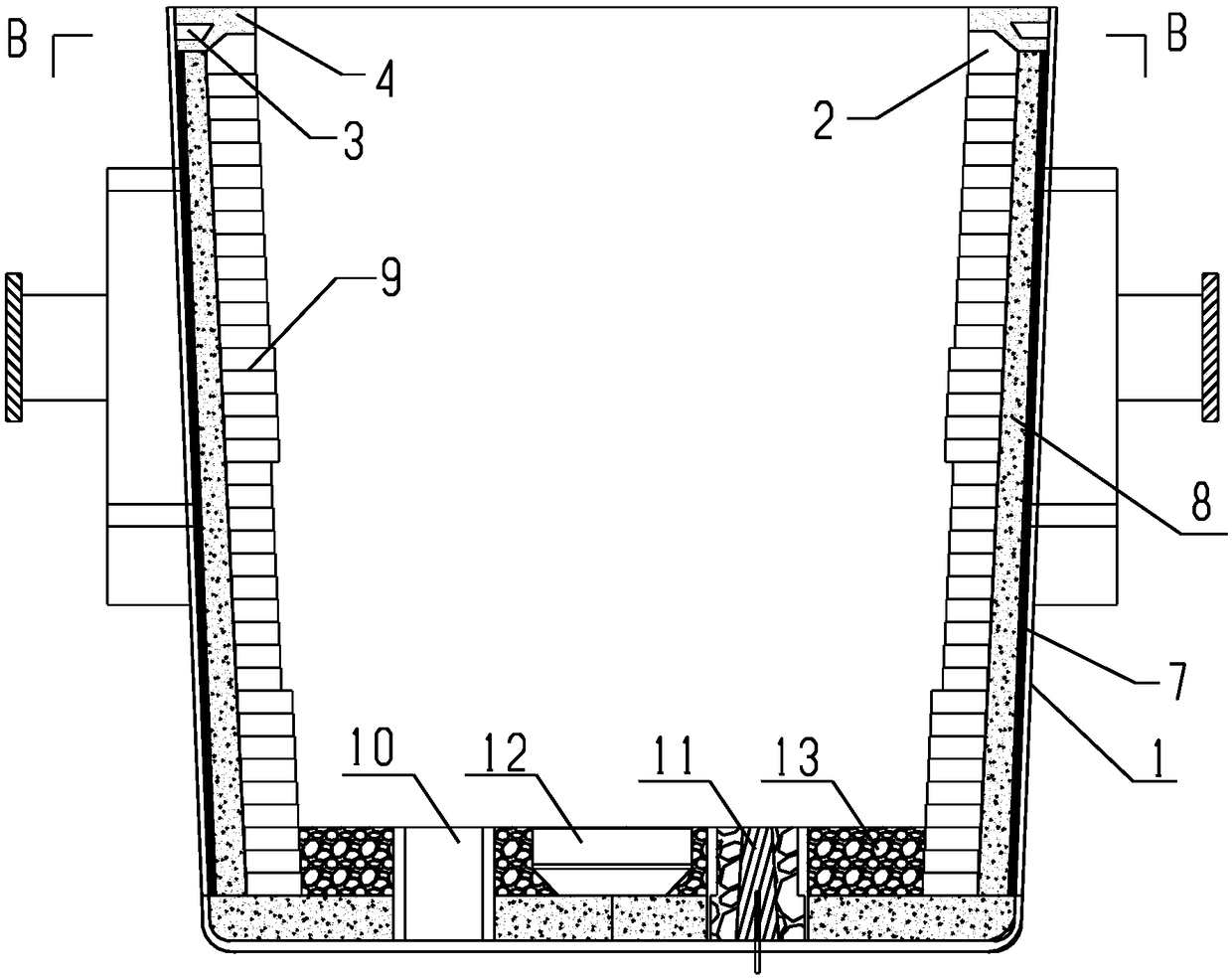

[0043] Embodiment: in a factory of Wuhan Iron and Steel Co., Ltd., the construction technology among the present invention is tested, and the tank bottom masonry structure and tank wall masonry structure of its molten iron tank are carried out normal masonry according to the masonry method of existing molten iron tank, and its The construction process of the tank along the masonry structure is: build the tank wall - weld the anchor - hang the tire membrane - pouring - demoulding - baking. Specific steps are as follows:

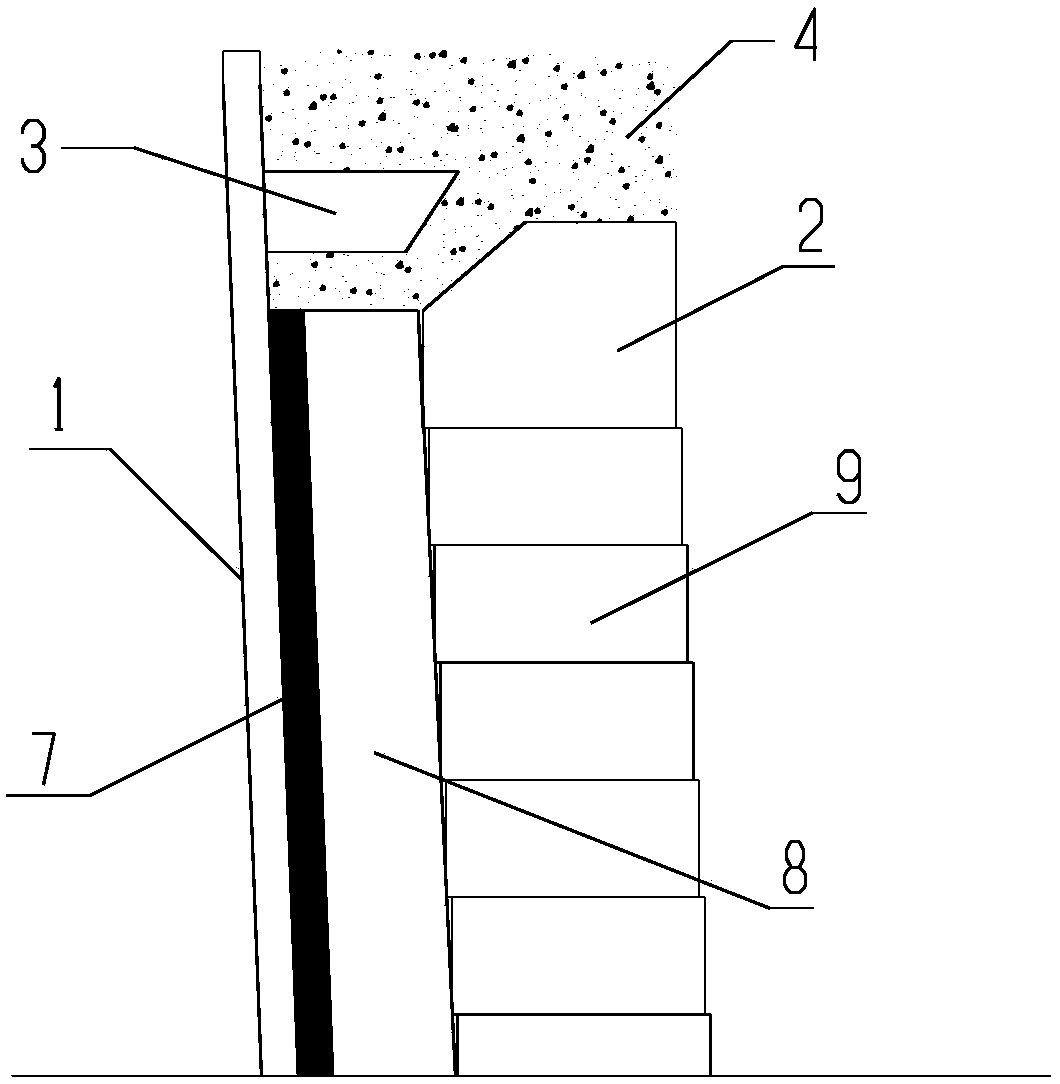

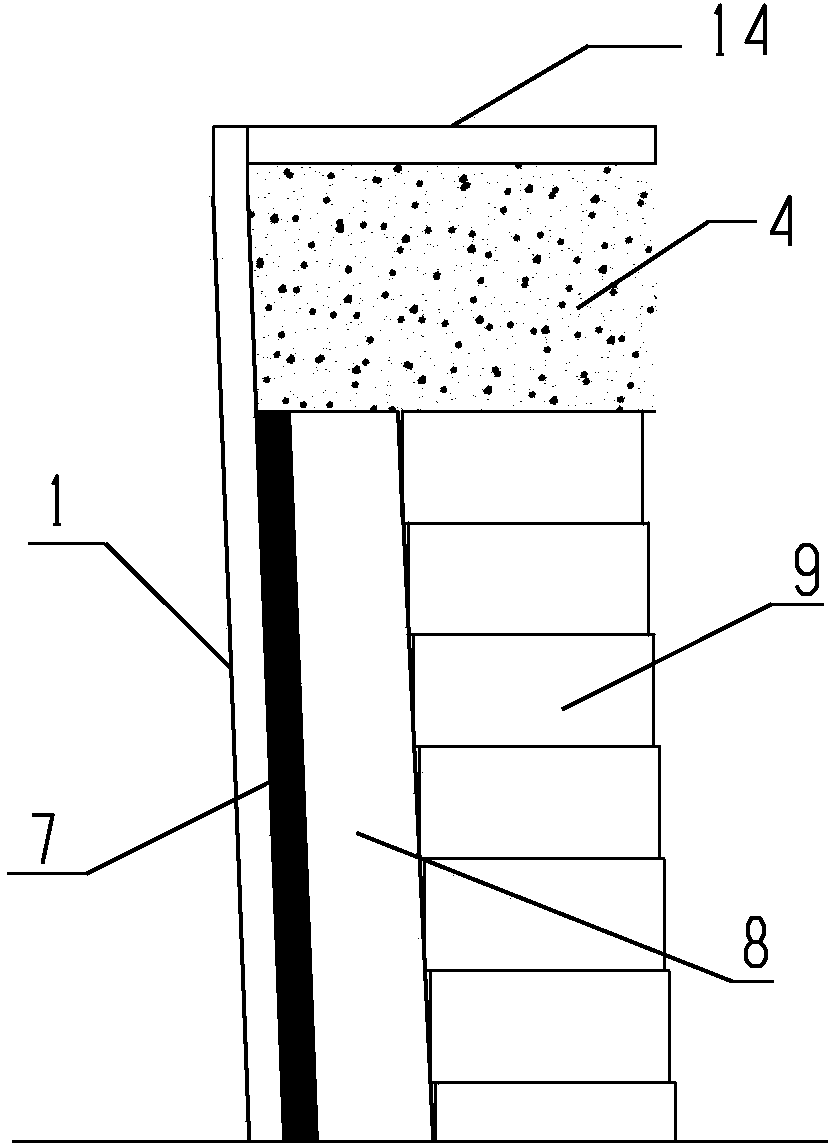

[0044] (1) First, use refractory bricks to build the 1st to 26th rings of the tank wall working layer, and build 12 rings of magnesia-carbon slag line bricks on the 27th to 38th rings of the tank wall brickwork layer 9, and start laying bricks at the 39th ring The magnesia-carbon tank along the brick 2; the magnesia-carbon tank along the brick 2 is a cuboid magnesia-carbon brick body with one corner cut off to form a special-shaped brick body with one end high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap