Apparatus for removing fine particles and dissolved pollutants in culture water body and method of apparatus

A technology for aquaculture water and fine particles, applied in chemical instruments and methods, flotation water/sewage treatment, adsorbed water/sewage treatment, etc. Make full use of ozone residues and other problems to achieve the effects of improving ozone utilization efficiency and sterilization efficiency, easy application and low transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

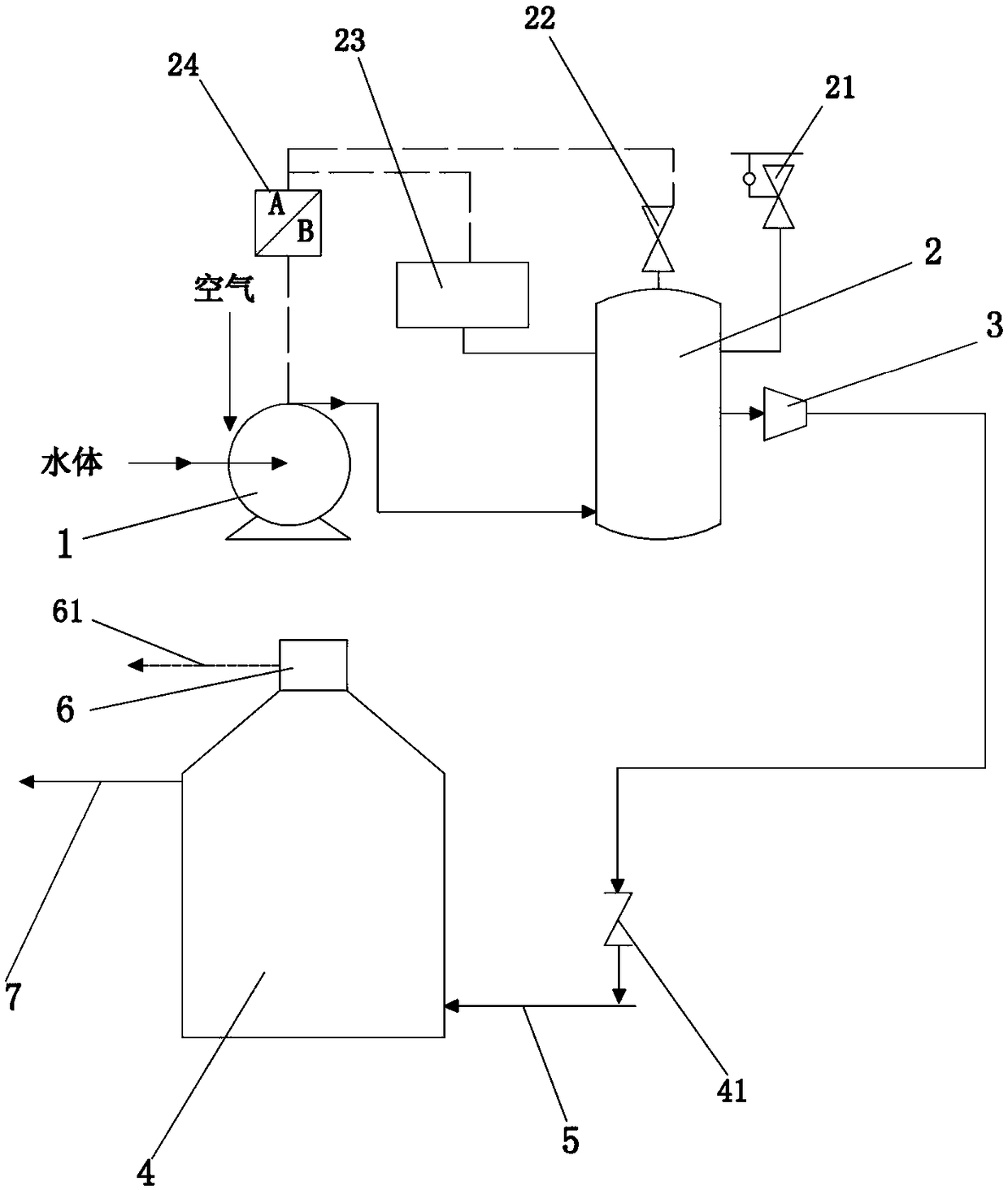

[0027] A device for removing fine particles and dissolved pollutants in aquaculture water, such as figure 1 As shown, it includes a booster pump 1, a high-pressure tank body 2, and an air flotation bucket 4. The booster pump 1 is provided with a clean water suction port and an air suction port, and the outlet of the booster pump 1 is connected to the bottom inlet of the high-pressure tank body 2. Pass; the outlet of the high-pressure tank 2 is connected with a pressure release device 3, and the outlet end of the pressure release device 3 communicates with the water inlet pipeline 5 of the air float bucket 4 through a connecting pipeline; the air float bucket 4 The top is connected with a bubble collector 6; the bubble collector 6 is provided with a sewage pipe 61, and the upper part of the air flotation bucket 4 is provided with a drain pipe 7.

[0028] In this embodiment, a safety relief valve 21 is connected to the high-pressure tank body 2 .

[0029] In this embodiment, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com