Preparation method of hot-blast non-woven fabric containing cellulose fiber

A technology of cellulose fiber and hot-air non-woven fabric, which is applied in the field of hygienic materials, and can solve the problems of cellulose fiber not having thermal adhesion, affecting use, and incompatibility of two-component fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail through the accompanying drawings and specific implementation examples below.

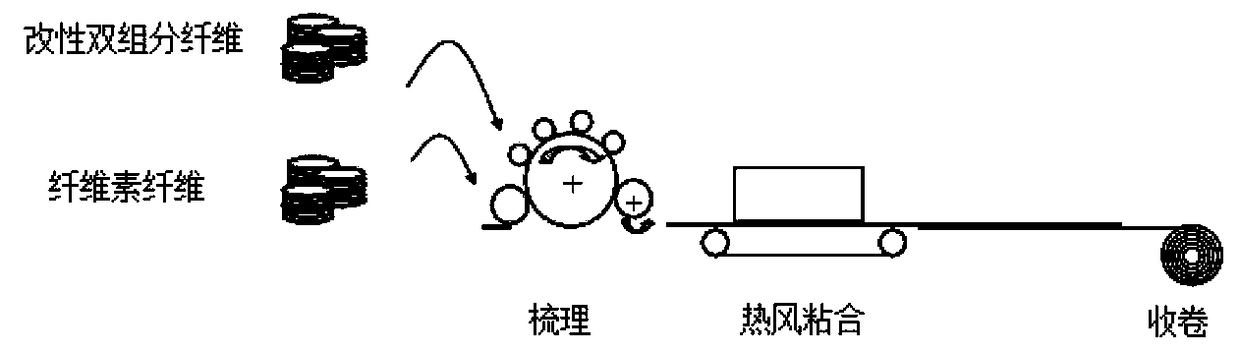

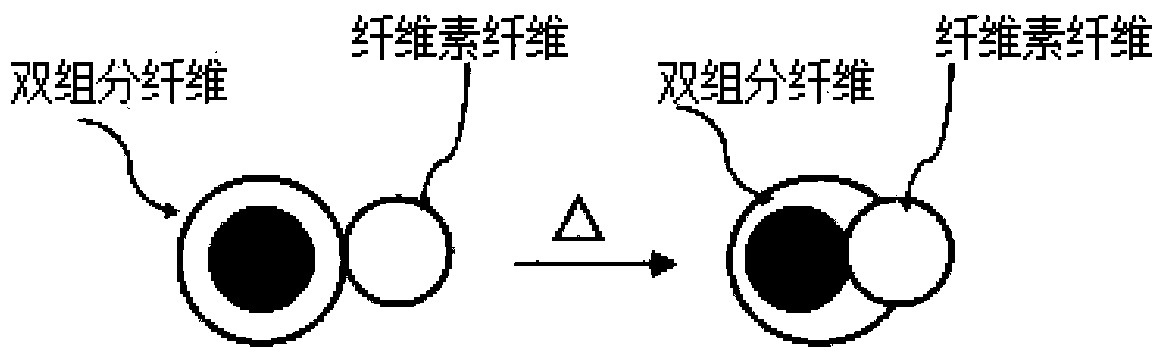

[0012] Such as figure 1 with figure 2 As shown, the present invention provides a method for preparing a hot-air non-woven fabric containing cellulose fibers, which is characterized in that: using a carding machine to mix and card the modified bi-component fibers and cellulose fibers, and use hot air bonding to obtain The hot-air non-woven fabric is finally sent to the winder for winding. Due to the use of modified bi-component fibers and cellulose fibers under the action of hot air, after the bi-component fiber cortex is melted, hydrogen bond cross-linking occurs with the cellulose, thereby Make the cellulose fiber and the two-component fiber bonded together, no fiber drop phenomenon occurs,

[0013] Preferably, the modified bicomponent fiber introduces a strong polar group into the skin layer, which has the characteristics of hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com