Glass fiber reinforced plastic drainage pit cover and manufacturing method thereof

A cellar cover and glass fiber reinforced plastic technology, which is applied to artificial islands, underwater structures, buildings, etc., can solve the problems of weak compressive strength, can not be too humid, and can not be too high internal temperature, and achieve long service life, waterproof and heat insulation effect. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

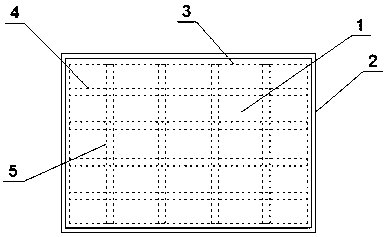

Image

Examples

Embodiment 1

[0019] The pit cover body 1 is made from the following raw materials in parts by mass: 30 parts of unsaturated polyester resin, 20 parts of quartz sand, 5 parts of glass fiber, 6 parts of silane coupling agent, 10 parts of asbestos fiber, 2 parts of talcum powder, 1 part of magnesium, 2 parts of calcium carbonate, 2 parts of aluminum hydroxide, 2 parts of antimony trioxide, 1 part of acetone, and 1 part of ultraviolet absorber.

[0020] The preparation method of this embodiment comprises the following steps:

[0021] Step 1: Add unsaturated polyester resin, quartz sand, silane coupling agent, asbestos fiber, talcum powder, magnesium oxide, and acetone into the mixer and stir, set the speed at 300 rpm, raise the temperature to 70°C, and set the time to 1h ;

[0022] Step 2: Add glass fiber, calcium carbonate, aluminum hydroxide, antimony trioxide, and ultraviolet absorber to high-speed stirring, set the speed to 800 rpm, raise the temperature to 100°C, and set the time to 1 ho...

Embodiment 2

[0025] The pit cover body 1 is made of the following raw materials in parts by mass: 30 parts of unsaturated polyester resin, 40 parts of quartz sand, 10 parts of glass fiber, 6 parts of silane coupling agent, 20 parts of asbestos fiber, 3 parts of talcum powder, 2 parts of magnesium, 3 parts of calcium carbonate, 3 parts of aluminum hydroxide, 3 parts of antimony trioxide, 2 parts of acetone, and 2 parts of ultraviolet absorber.

[0026] The preparation method of this embodiment comprises the following steps:

[0027] Step 1: Add unsaturated polyester resin, quartz sand, silane coupling agent, asbestos fiber, talcum powder, magnesium oxide, and acetone into the blender and stir, set the speed to 400 rpm, raise the temperature to 80°C, and set the time to 1.5 h;

[0028] Step 2: Continue to add glass fiber, calcium carbonate, aluminum hydroxide, antimony trioxide, and ultraviolet absorber to high-speed stirring, set the speed to 1000 rpm, raise the temperature to 110°C, and s...

Embodiment 3

[0031] The pit cover body 1 is made of the following raw materials in parts by mass: 35 parts of unsaturated polyester resin, 30 parts of quartz sand, 7 parts of glass fiber, 8 parts of silane coupling agent, 15 parts of asbestos fiber, 4 parts of talcum powder, 2 parts of magnesium, 4 parts of calcium carbonate, 4 parts of aluminum hydroxide, 4 parts of antimony trioxide, 2 parts of acetone, and 2 parts of ultraviolet absorber.

[0032] The preparation method of this embodiment comprises the following steps:

[0033] Step 1: Add unsaturated polyester resin, quartz sand, silane coupling agent, asbestos fiber, talcum powder, magnesium oxide, and acetone into the mixer and stir, set the speed to 600 rpm, raise the temperature to 90°C, and set the time to 2h ;

[0034] Step 2: Continue to add glass fiber, calcium carbonate, aluminum hydroxide, antimony trioxide, and ultraviolet absorber to high-speed stirring, set the speed to 1200 rpm, raise the temperature to 120°C, and set th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com