Sliding valve vacuum pump

A slide valve vacuum pump and vacuum pumping technology, which is applied to pump elements, parts of pumping devices for elastic fluids, and parts of rotary piston type/swing piston type pumps, etc., can solve the problem of oil storage without dirty oil Installation and discharge process are inconvenient, easy to cause pollution and other problems, to achieve the effect of reducing pollution, good environmental protection and reducing oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

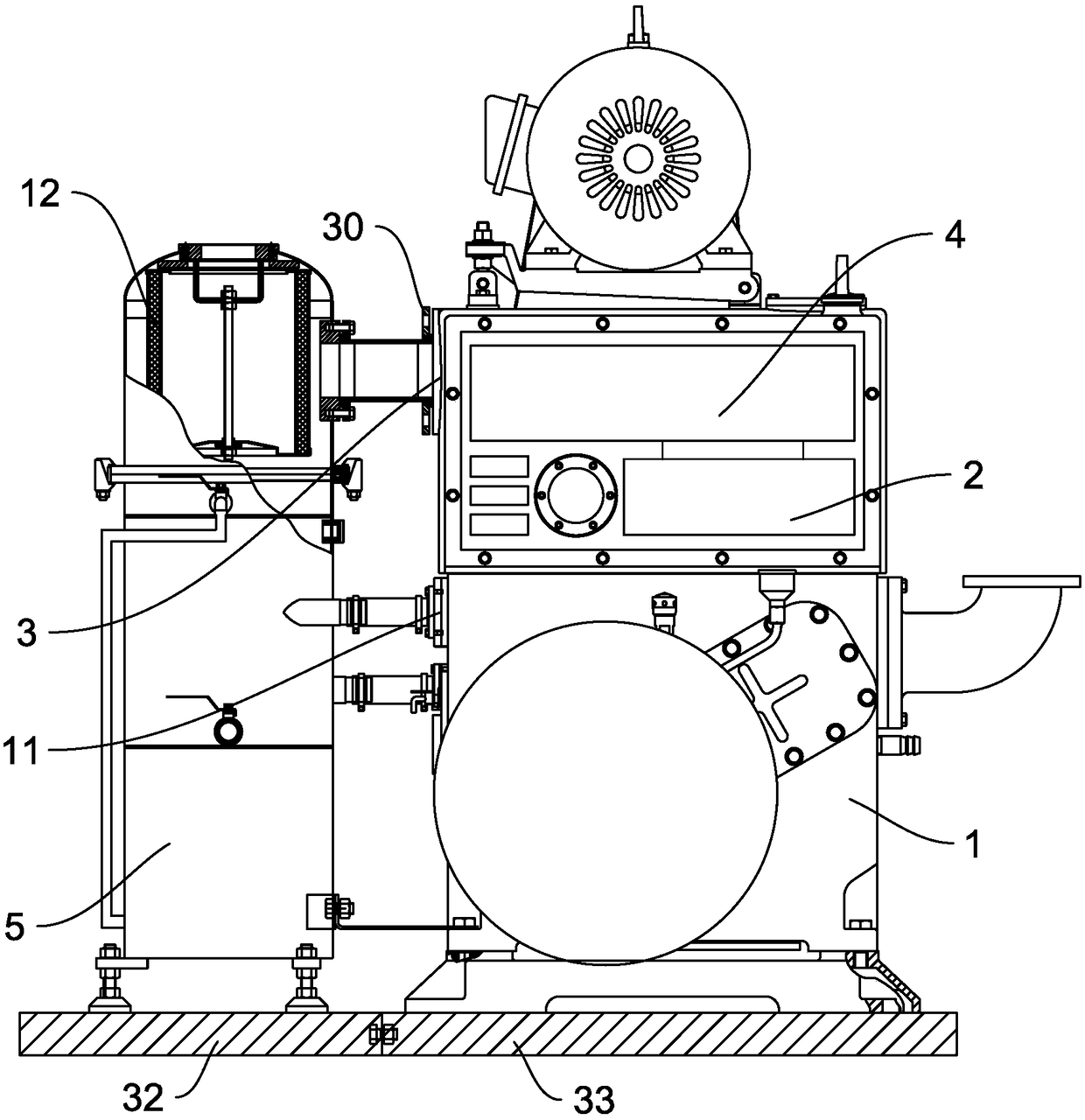

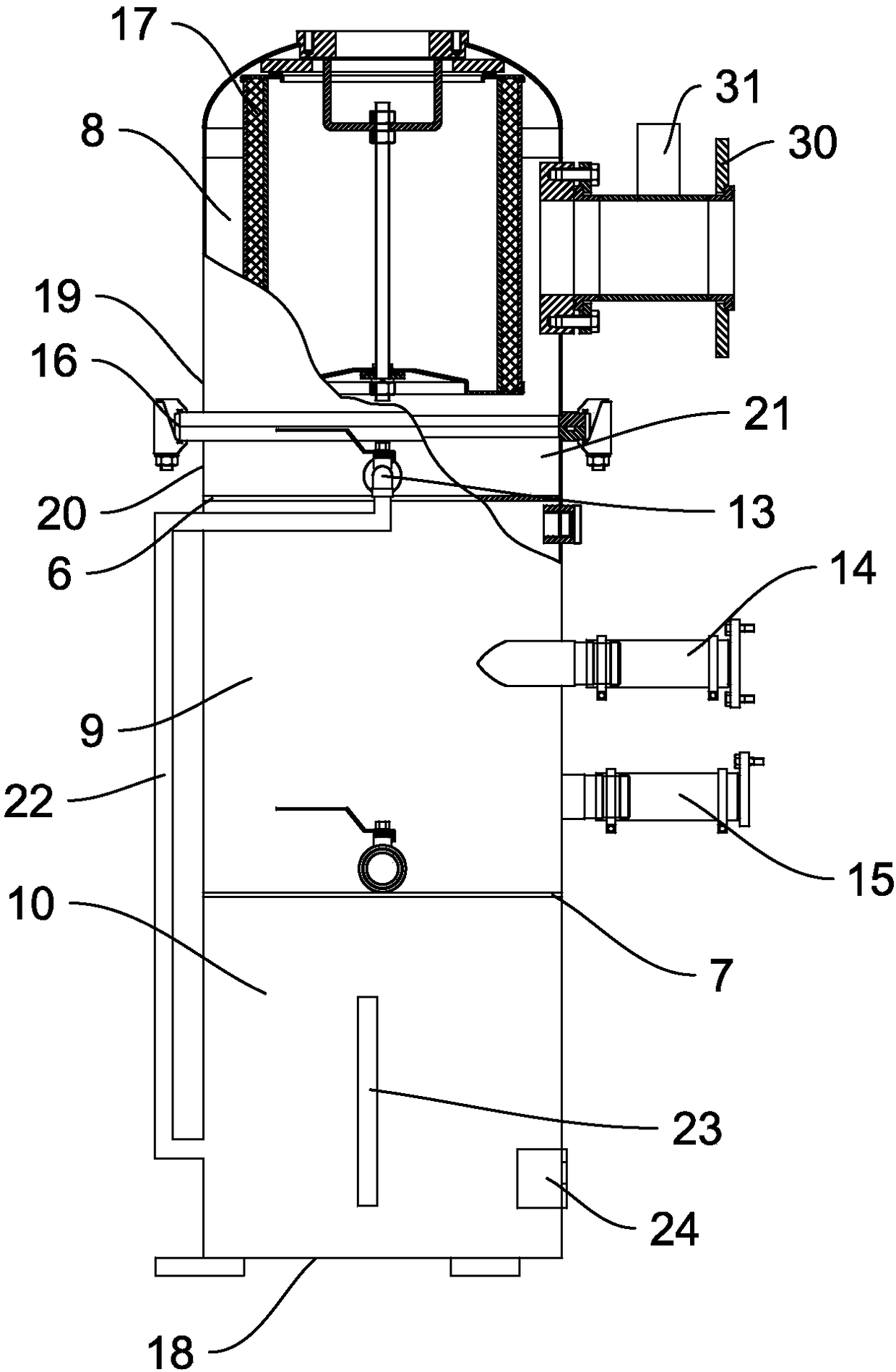

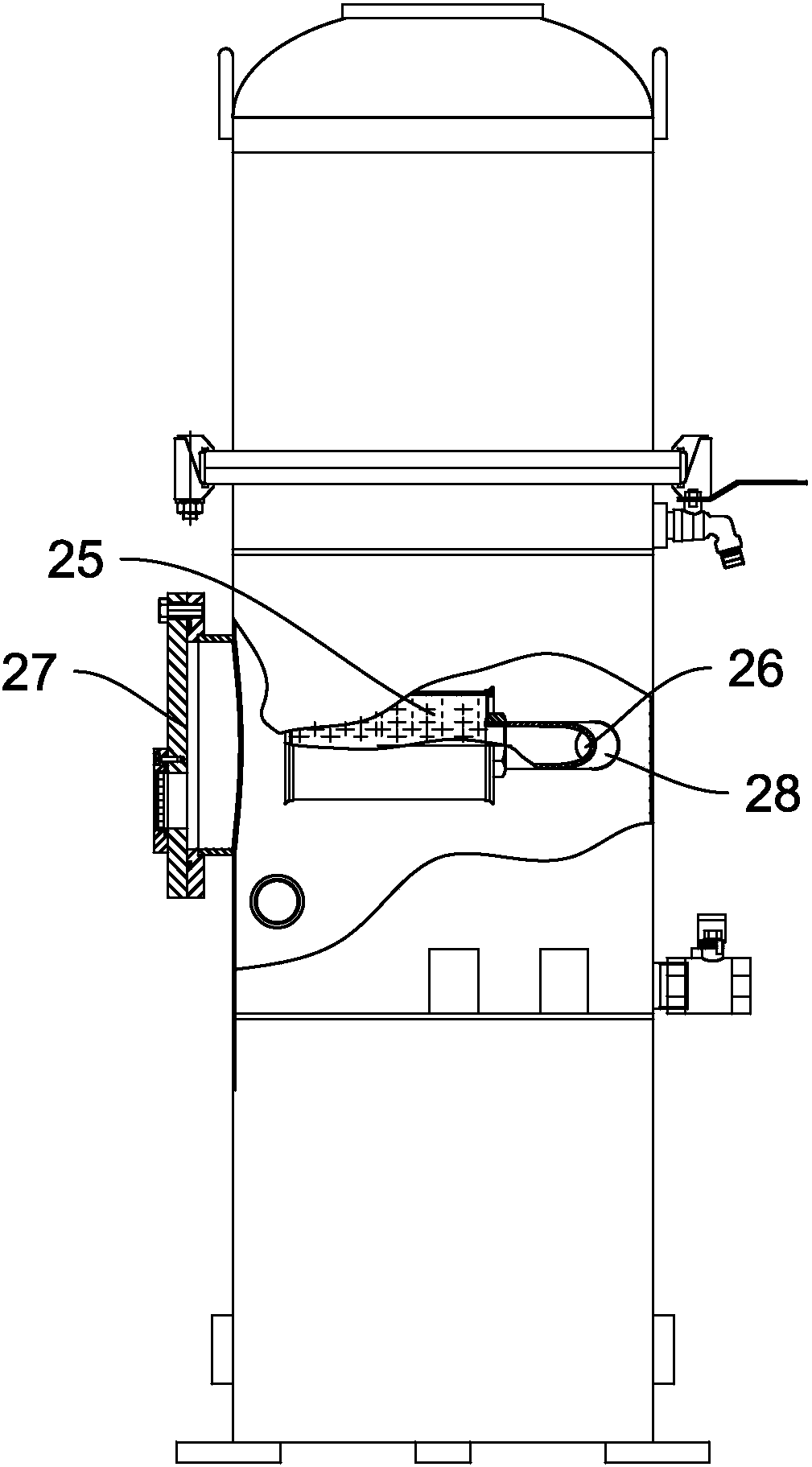

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] see figure 1As shown, the slide valve vacuum pump includes a pump body 1 for vacuum pumping and an oil pool box 2 connected to the oil gas discharge port 3 of the pump body 1. An oil gas separator 4 is arranged above the oil gas discharge port 3 of the pump body 1, and the oil pool The exhaust port 11 of the tank 2 is connected with the auxiliary oil tank 5, and the auxiliary oil tank 5 is formed by splicing the upper box body 17 and the lower box body 18 through the flange 16, and the inner cavity of the auxiliary oil tank 5 passes through the upper partition plate 6 and the lower partition plate. The board 7 is divided into three independently sealed cavities: an upper cavity 8, a middle cavity 9, and a lower cavity 10. Specifically, the joint of the upper box 17 and the lower box 18 of the present invention is located on the upper cavity 8, Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com