Conductive thin film and method for improving conductivity of conductive thin film

A conductive thin film and conductive technology, which is applied in the direction of equipment for manufacturing conductive/semiconductive layers, conductive layers on insulating carriers, circuits, etc., can solve the problems of increasing microwave time, thermal deformation of flexible substrates, and inability of resistance nodes Welding or complete welding and other problems to achieve the effect of reducing sheet resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0043] Embodiment 2 is only carrying out composite treatment with metal oxide sol to conductive film;

Embodiment 3

[0044] Embodiment 3 is to carry out composite treatment with metal oxide sol first to conductive film, and then carry out microwave treatment;

Embodiment 4

[0045] Embodiment 4 is to first carry out microwave treatment to the conductive film, and then carry out composite treatment with metal oxide sol;

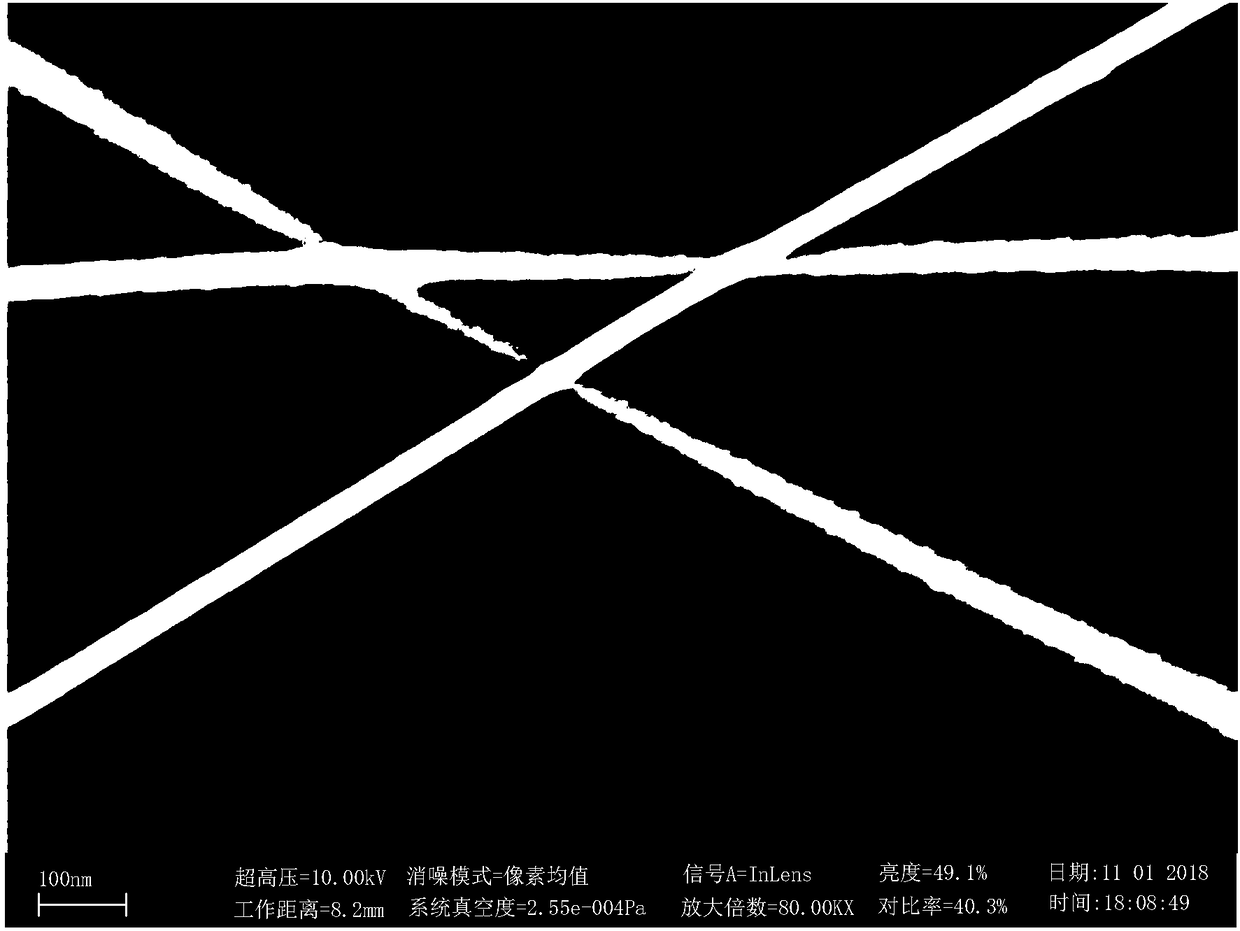

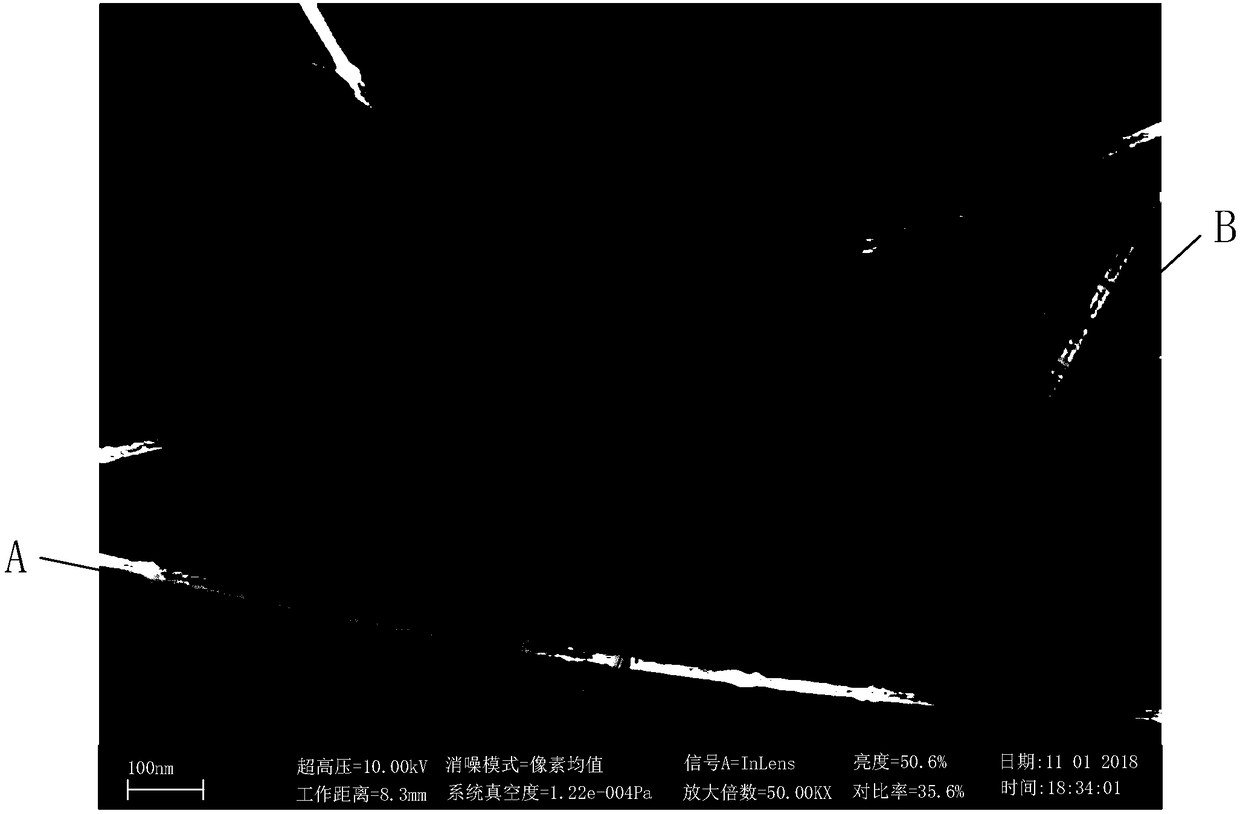

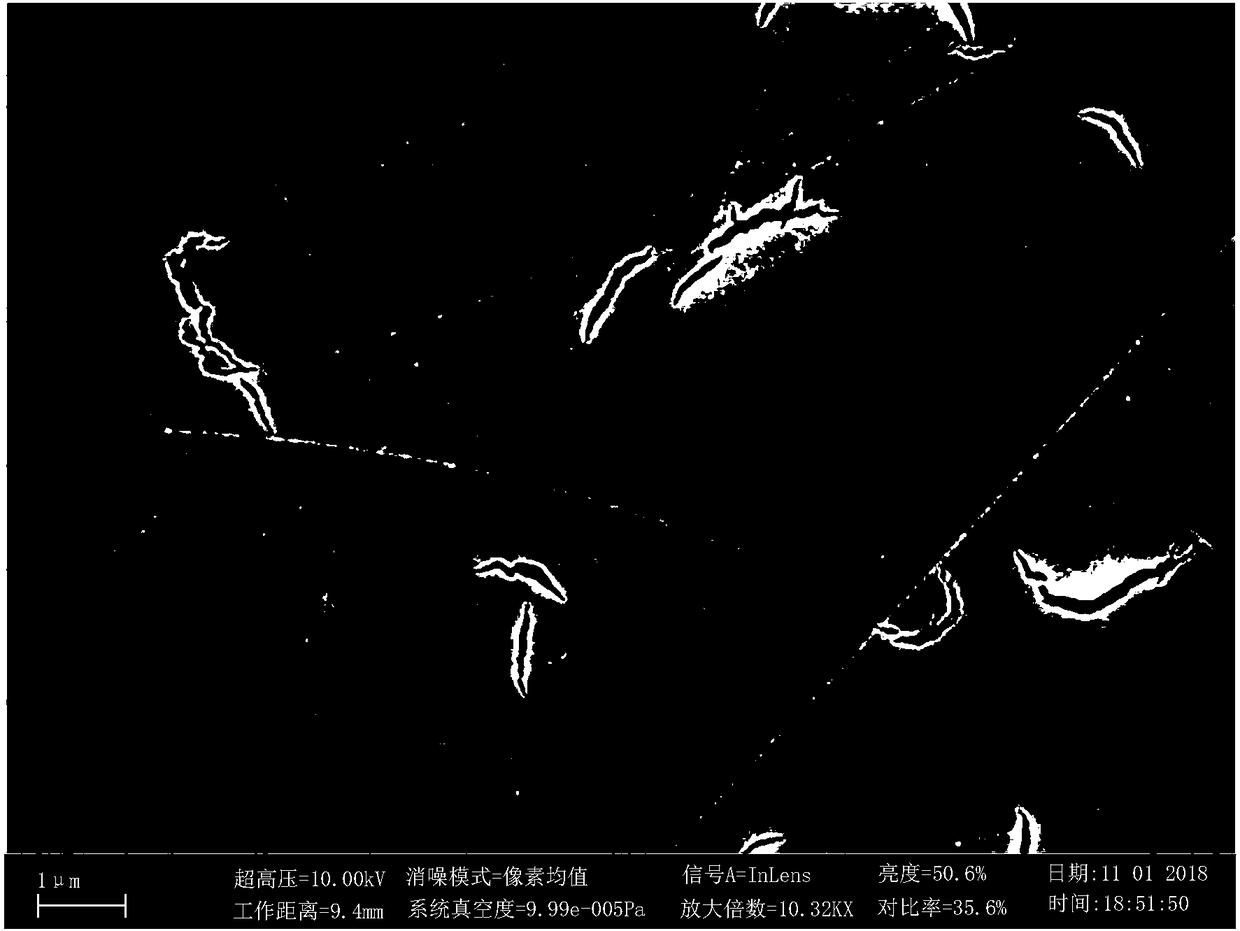

[0046] The metal nanowire 1 selected in Embodiment 1 to Embodiment 4 is silver nanowire, the flexible substrate material selected is PET material, and the metal oxide sol 2 selected is zinc oxide sol. The specific implementation process is as follows

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com