Reluctance suppression type motor winding skeleton and linear voice coil motor

A technology of winding bobbins and voice coil motors, which is applied in the direction of windings, electrical components, electromechanical devices, etc., can solve problems such as hindering the movement of winding bobbins, low system flexibility, and slow response speed of linear voice coil motors, so as to improve the system The effects of flexibility, improved response speed, and reduced movement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

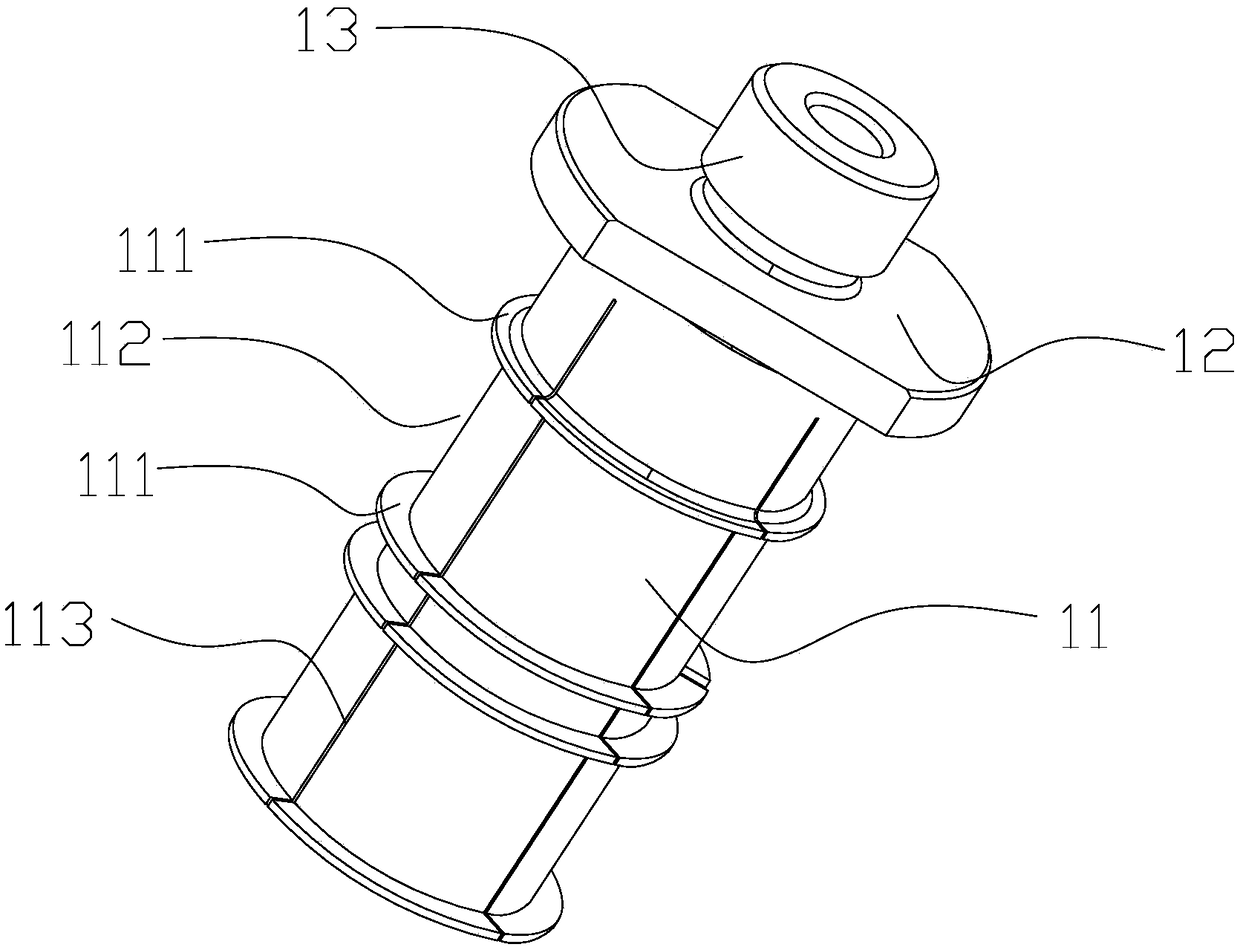

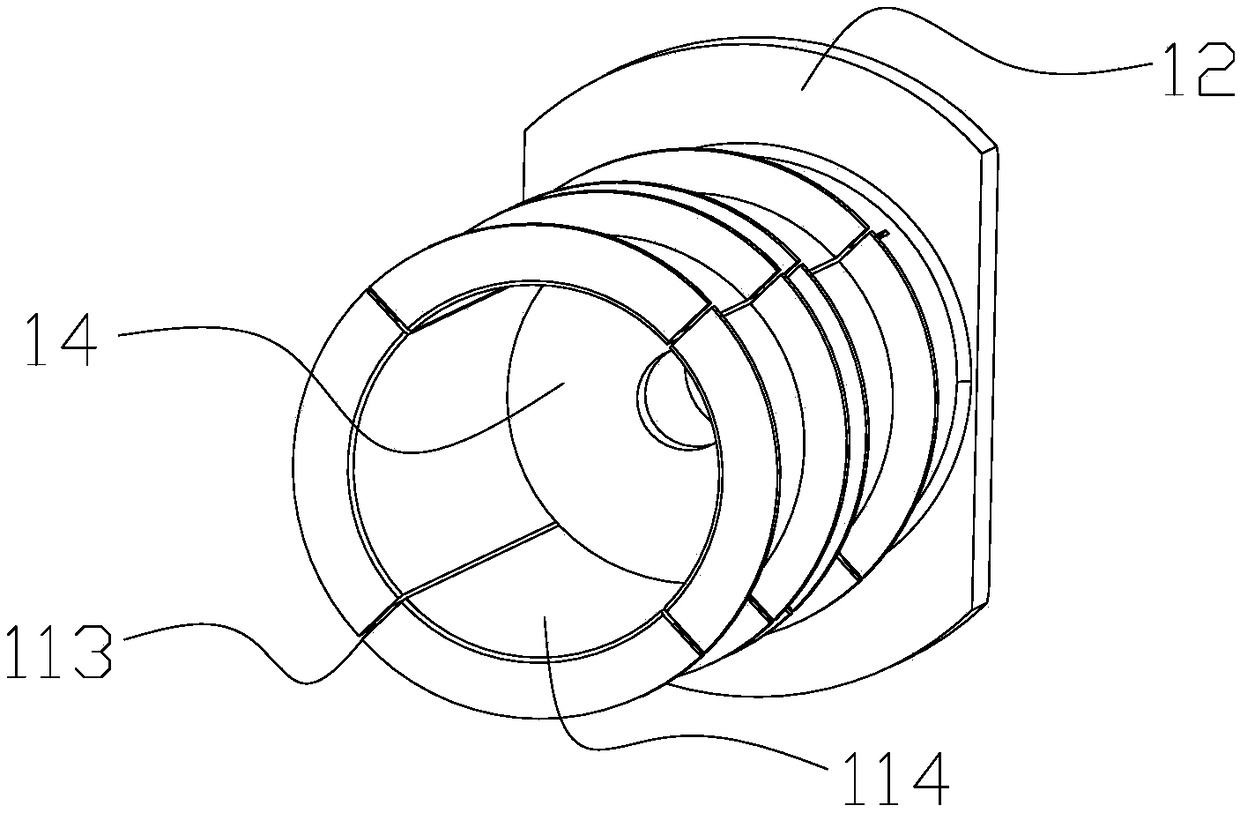

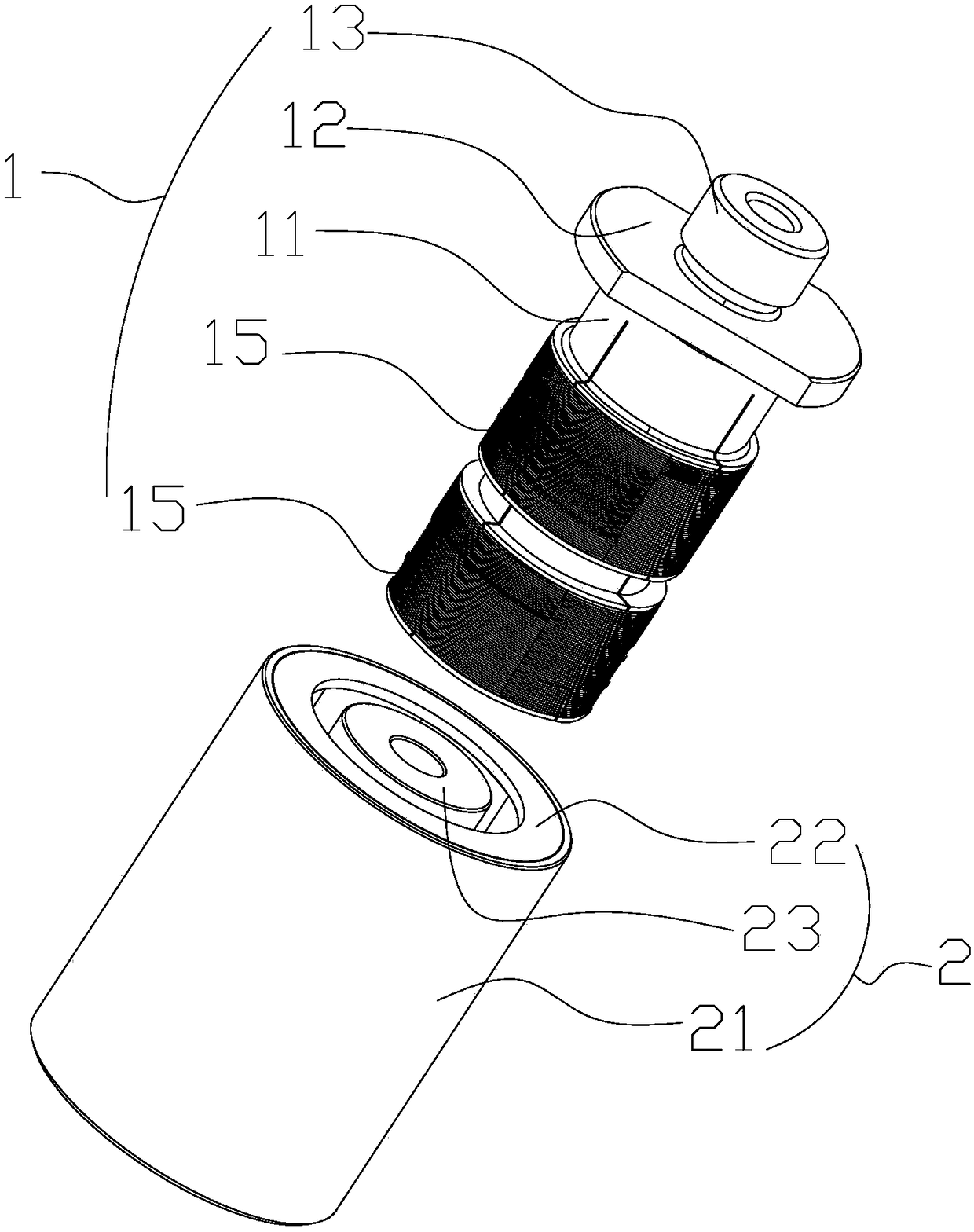

[0029] combine figure 1 and figure 2 , the structure of the motor winding skeleton described in the present invention will be described in detail. The winding skeleton includes a cylindrical body 11. Preferably, the material of the body 11 is any one of aluminum alloy, magnesium aluminum alloy and titanium alloy, which have the advantages of light weight and high mechanical strength. When the winding skeleton moves along the motor stator 2 with high frequency and fast linear motion, it can provide sufficient supporting force and tensile and torsional strength. On the top surface of the main body 11 there is an upper cover 12 for position-limiting function, and on the upper plane of the upper cover 12, a terminal post 13 is installed. On the outer surface of the body 11, there are four baffles 111 arranged around the body 11 and arranged axially. The baffles 111 are a certain distance above the side of the body 11. The blocking pieces 111 respectively form two winding slots...

Embodiment 2

[0033] The present invention also provides another embodiment of the linear voice coil motor, which differs from Embodiment 1 in that the annular structure formed by splicing a plurality of dispersed magnetic tiles 222 is replaced by a single annular structure magnetic tile, and the two The above-mentioned single ring-shaped magnetic tile is connected to the outer yoke body 21 through an aluminum ring 221 , and a pressure ring 223 is installed on the top of the upper single ring-shaped magnetic tile. Using the above solution can greatly reduce the difficulty of processing and assembly, and make the overall structure of the linear voice coil motor simpler, thereby effectively reducing the failure rate and solving the problem of cumbersome replacement and maintenance caused by the damage of the dispersed magnetic tile 222 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com