A mixed fruit and vegetable juice making device

A technology for mixing fruits and vegetables, fruits and vegetables, applied in beverage preparation devices, household machinery for filtering food, kitchen utensils, etc. Improve drinking taste, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

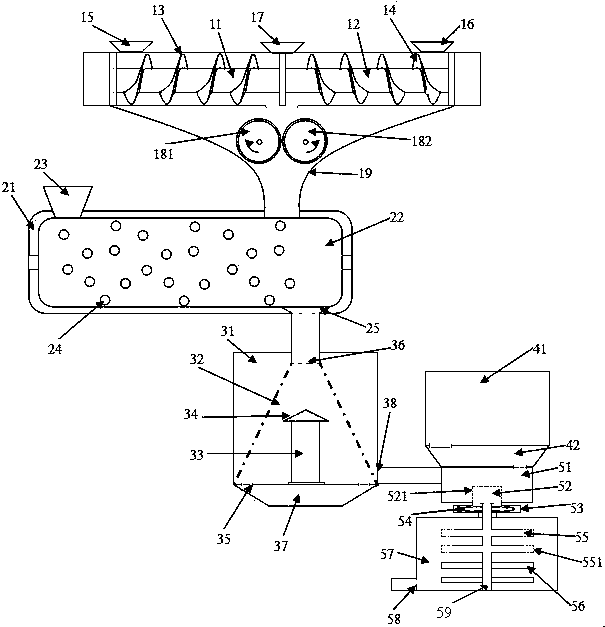

[0028] Such as figure 1 As shown, a mixed fruit and vegetable juice making device includes a crushing chamber, a deep crushing chamber, a separation chamber, an organic acid ice-making chamber and a finished product chamber.

[0029] The crushing chamber includes a crushing chamber casing, a first crushing shaft, a second crushing shaft, a first helical blade, a second helical blade, a first fruit and vegetable inlet, a second fruit and vegetable inlet, an ice water inlet, a first rolling roller, a second Two crushing rollers and the outlet of the crushing chamber; the first crushing shaft and the second crushing shaft are arranged laterally opposite to each other on the top of the shell of the crushing chamber, and first helical blades are respectively arranged on the first crushing shaft and the second crushing shaft With the second helical blade, the helical directions of the first helical blade and the second helical blade are oppositely set, and the top of the crushing ch...

Embodiment 2

[0044] A mixed fruit and vegetable juice making device includes a crushing chamber, a deep crushing chamber, a separation chamber, an organic acid ice making chamber and a finished product chamber.

[0045] The crushing chamber includes a crushing chamber casing, a first crushing shaft, a second crushing shaft, a first helical blade, a second helical blade, a first fruit and vegetable inlet, a second fruit and vegetable inlet, an ice water inlet, a first rolling roller, a second Two crushing rollers and the outlet of the crushing chamber; the first crushing shaft and the second crushing shaft are arranged laterally opposite to each other on the top of the shell of the crushing chamber, and first helical blades are respectively arranged on the first crushing shaft and the second crushing shaft With the second helical blade, the helical directions of the first helical blade and the second helical blade are oppositely set, and the top of the crushing chamber shell at the beginning...

Embodiment 3

[0059] A mixed fruit and vegetable juice making device includes a crushing chamber, a deep crushing chamber, a separation chamber, an organic acid ice making chamber and a finished product chamber.

[0060] The crushing chamber includes a crushing chamber casing, a first crushing shaft, a second crushing shaft, a first helical blade, a second helical blade, a first fruit and vegetable inlet, a second fruit and vegetable inlet, an ice water inlet, a first rolling roller, a second Two crushing rollers and the outlet of the crushing chamber; the first crushing shaft and the second crushing shaft are arranged laterally opposite to each other on the top of the shell of the crushing chamber, and first helical blades are respectively arranged on the first crushing shaft and the second crushing shaft With the second helical blade, the helical directions of the first helical blade and the second helical blade are oppositely set, and the top of the crushing chamber shell at the beginning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com