Composite porous adsorption material based on oily sludge and waste plastic PET and preparation method thereof

A technology of porous adsorption materials and waste plastics, which is applied in the field of resource utilization of solid waste, can solve the problems of aggravating the earth's white pollution and threatening the living environment of human beings, and achieve remarkable adsorption performance, reduce environmental pollution problems, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Using oily sludge and waste plastic PET as raw materials, oily sludge is centrifuged and dehydrated and dried to remove most of the water, and then mixed evenly with waste plastic (PET) after washing, drying, and crushing. Waste plastic PET accounts for the two after mixing. The ratio of the total mass is 30%. Put the homogeneous mixture of the two into a quartz boat, and perform pyrolysis treatment in the nitrogen atmosphere of the tube furnace: raise the temperature at a heating rate of 5°C / min, and keep it at 500°C for 4h to obtain the finished composite porous adsorption material.

[0030] Adsorption experiment: The composite porous adsorption material prepared in this example was tested for adsorption performance. Add 500 mg of composite porous material into 50 mL of 1000 mg / L methylene blue solution, shake for 24 hours, and measure the adsorption capacity of the filtrate after filtration to be 20.76 mg / g.

Embodiment 2

[0032] Using oily sludge and waste plastic PET as raw materials, the oily sludge is centrifuged and dehydrated and dried to remove most of the water, and then mixed evenly with waste plastic PET after washing, drying, and crushing. Waste plastic PET accounts for the total mass of the two after mixing The ratio is 50%. Put the homogeneous mixture of the two into a quartz boat, and perform pyrolysis treatment in the nitrogen atmosphere of the tube furnace: raise the temperature at a heating rate of 5°C / min, and keep it at 500°C for 4h to obtain the finished composite porous adsorption material.

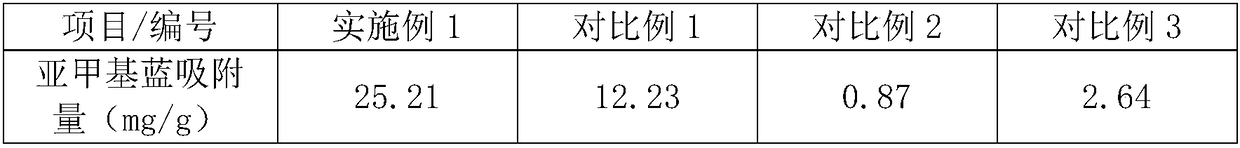

[0033] Adsorption experiment: The composite porous adsorption material prepared in this example was tested for adsorption performance. Add 500 mg of composite porous material into 50 ml of 1000 mg / l methylene blue solution, shake for 24 hours, and measure the adsorption capacity of the filtrate after filtration to be 25.21 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com