A method for the controllable preparation of two-dimensional organic carbon nitrogen from urea

A technology of organic carbon and urea, which is applied in the field of two-dimensional organic material preparation, can solve the problems of urea failure, urea excess, and urea not being used, and achieve excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

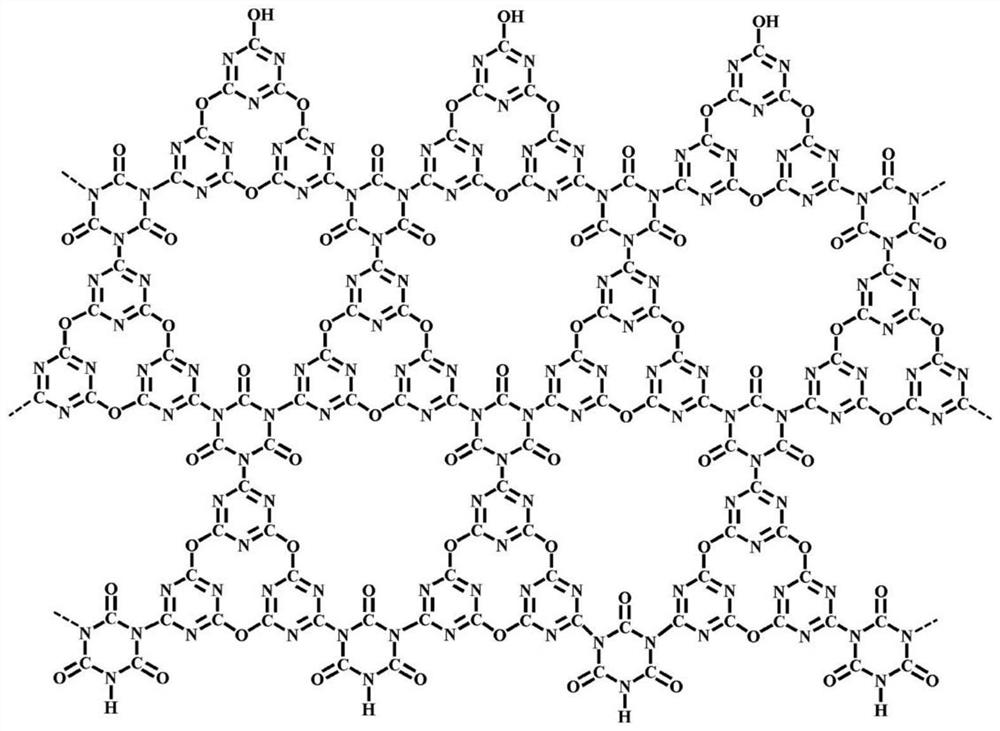

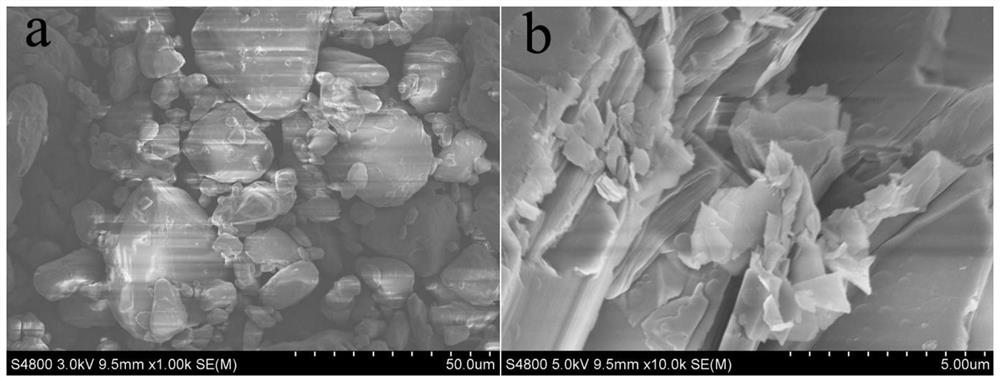

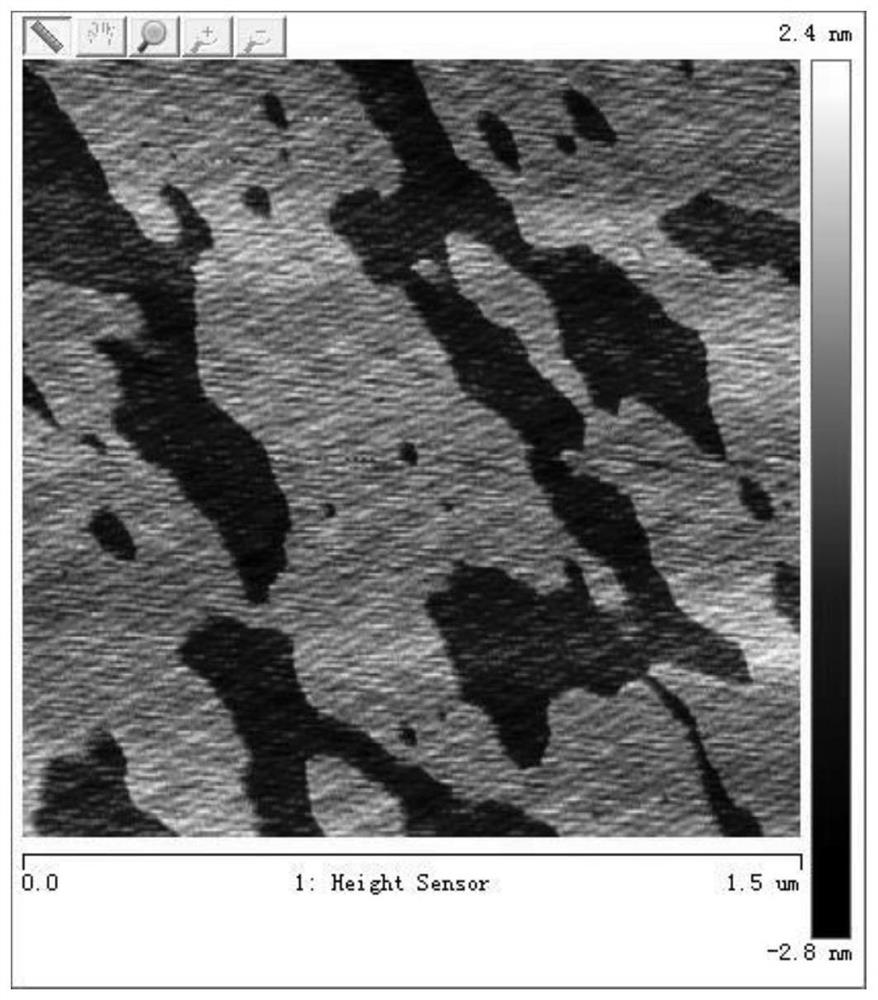

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, two-dimensional organic carbon-nitrogen materials are controlledly prepared from urea, and the specific steps are as follows:

[0025] (1) Disperse 0.5 gram of urea powder in 30 milliliters of distilled water, and stir with ultrasonic magnetic force for 60 minutes to form a dispersion solution;

[0026] (2) transfer the precursor obtained in step (1) to 50 milliliters of Teflon-lined inner linings, and then place them in a stainless steel autoclave;

[0027] (3) Then the autoclave is sealed and kept at a high temperature of 100°C for 6 hours, then naturally cooled to room temperature;

[0028] (4) The product is filtered out, the precipitate is washed several times with distilled water, and finally dried in a vacuum oven at 80°C for 24 hours;

[0029] (5) Heat the powder obtained in step (4) to 300° C. in a nitrogen protective atmosphere in a vacuum tube furnace, and keep it warm for 1.5 hours to obtain a two-dimensional organic carbon-nitrogen mate...

Embodiment 2-6

[0031] The difference between this group of embodiments and embodiment 1 is: in the step (5), the heat preservation time is shown in the table below

[0032] Heat preservation time in table 2 embodiment 2-6 step (5)

[0033]

[0034] Wherein embodiment 2 heat preservation time is 0h, namely embodiment 2 does not have step (5), the photocatalytic performance contrast of embodiment 1-6 gained organic carbon nitrogen material sees Figure 4 , it can be seen that the photocatalytic ability of the organic carbon nitrogen material obtained in this group of examples is higher than that of the currently used C 3 N 4 It should be high, and the photocatalytic performance of the embodiment is the highest, and its hydrogen production rate is 1325.1μmol h -1 g -1 , and from Figure 4 It can be seen from d that the cycle catalytic ability of Example 1 is very good, which proves that the organic carbon nitrogen material obtained in the present invention has good stability.

Embodiment 7

[0036] The difference between this embodiment and embodiment 1 is that in step (1), the consumption of urea powder and distilled water are respectively changed to 0.3 grams of urea and 30 milliliters of distilled water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com