Three-dimensional welding line automatic recognition device and method

An automatic identification, three-dimensional technology, applied in welding accessories, image data processing, 3D modeling, etc., can solve problems such as electromagnetic interference, high temperature radiation, waste of manpower and material resources, and achieve the effect of improving accuracy, improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and embodiment and the present invention will be further described.

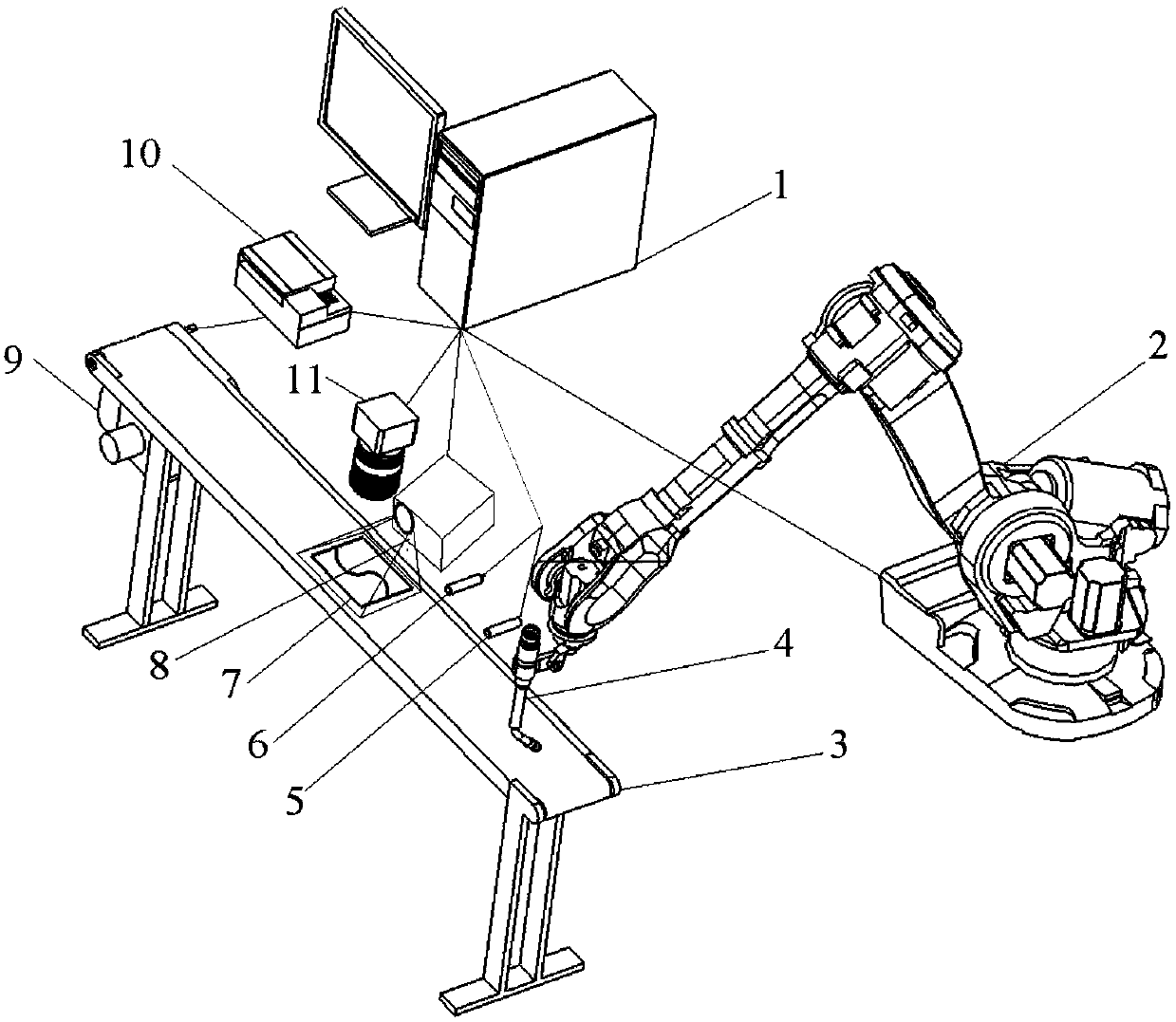

[0041] Such as figure 1As shown, the specific implementation of the present invention comprises a DLP projector 8, a CCD industrial camera 11, a welding robot 2, a conveyor belt 3, a servo motor 9 and two photoelectric sensors 5,6; The wheel is connected to the servo motor 9, and the workpiece 7 to be welded is placed on the conveyor belt 3, and the conveyor belt 3 is driven by the servo motor 9 to transport the workpiece 7 to be welded; the upper side of the conveyor belt 3 entrance is provided with a CCD industrial camera 11 and a DLP projector 8, and the conveyor belt 3 A welding torch 4 is arranged above the exit side, and the welding torch 4 is connected to the welding robot 2, and the welding torch 4 is controlled by the welding robot 2 to move to weld the welding workpiece 7; between the welding torch 4 and the DLP projector 8 / CCD industrial camera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com