Multifunctional dismounting and mounting device for container semi-automatic twist lock

A container and multi-functional technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems affecting the safety and health of dismantling locks, exhaust pollution, and restrictions on the improvement of container terminal operation efficiency, etc., to achieve comprehensive operation The effect of improving efficiency, reducing staff, and improving safety management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

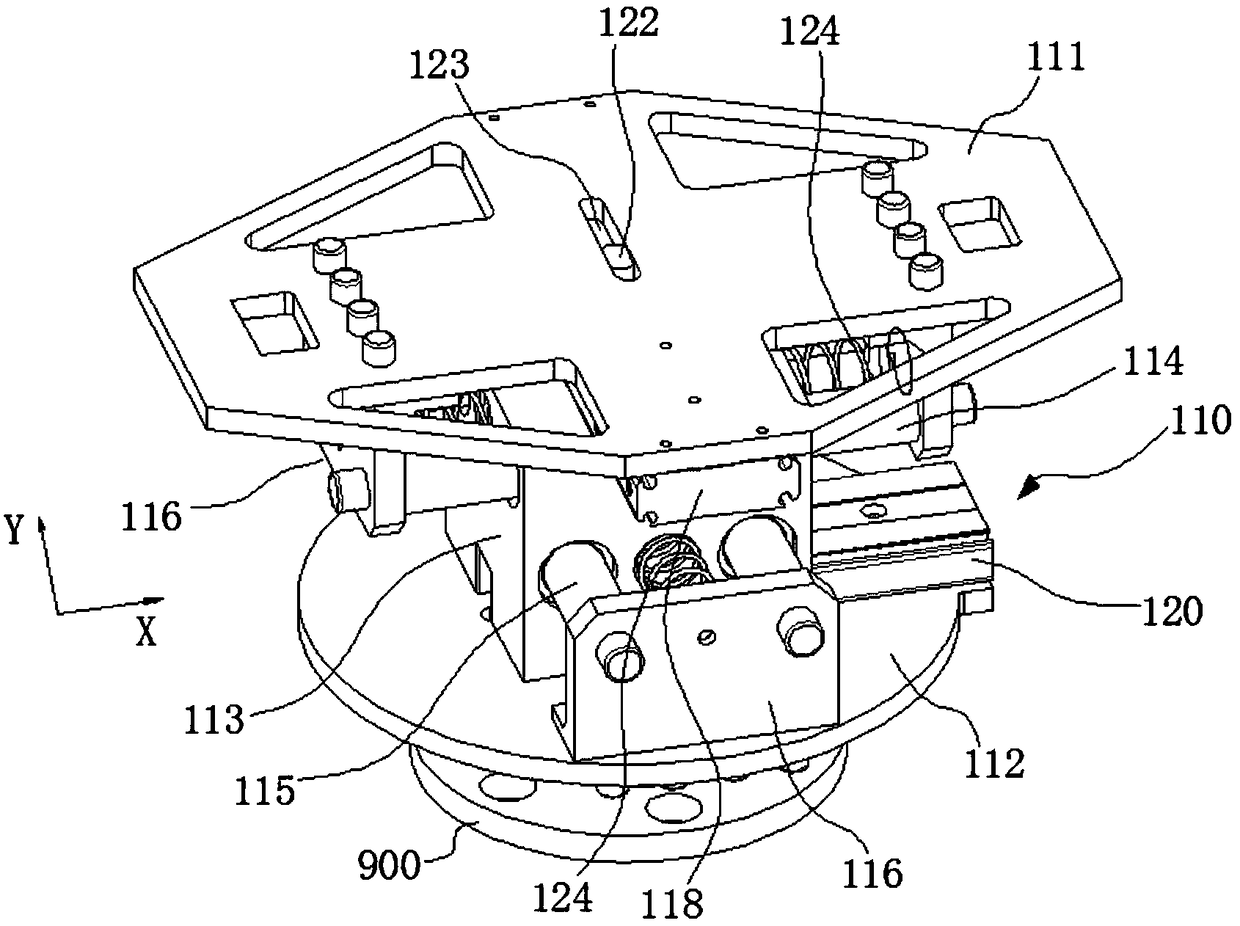

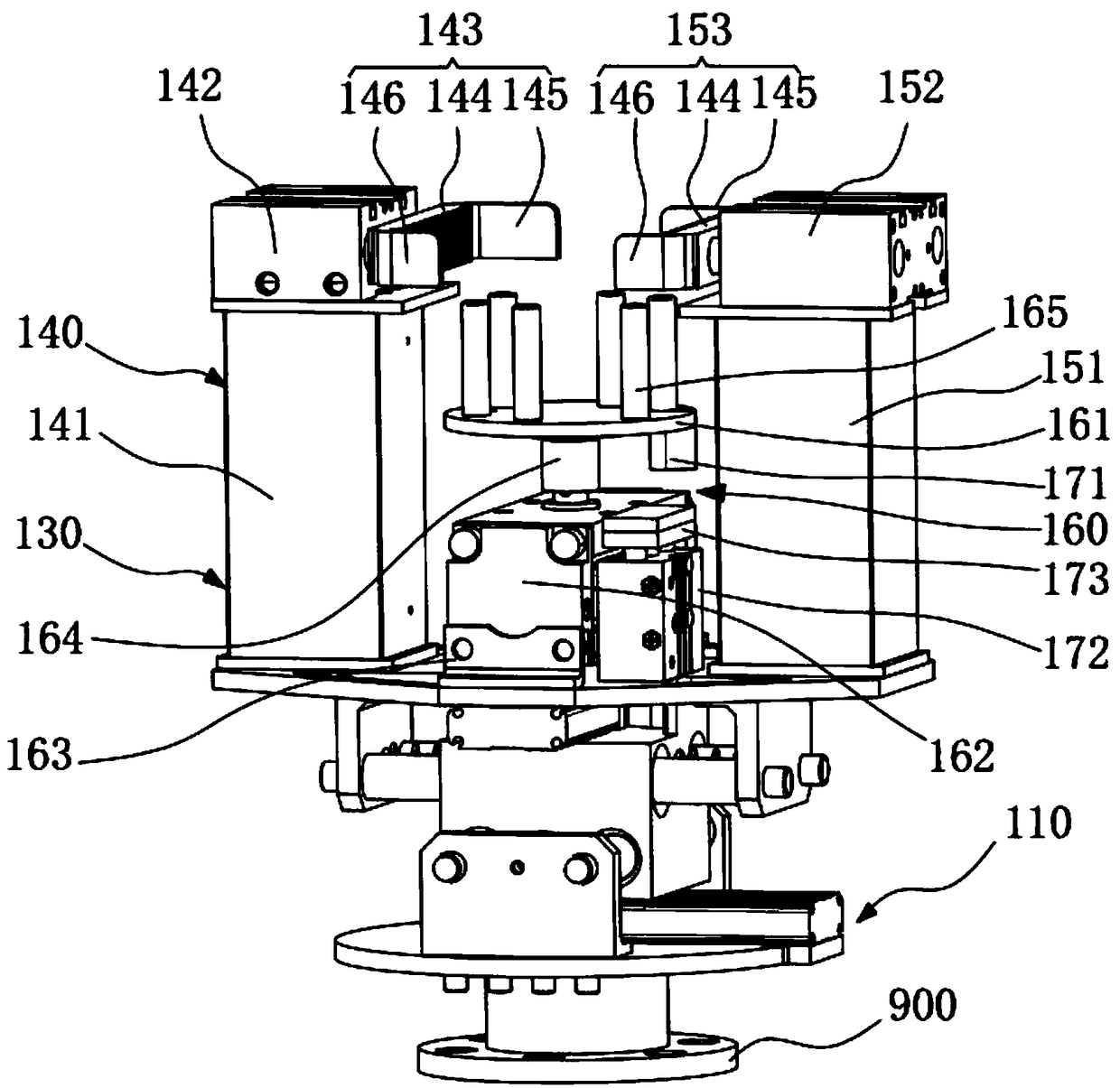

[0037] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

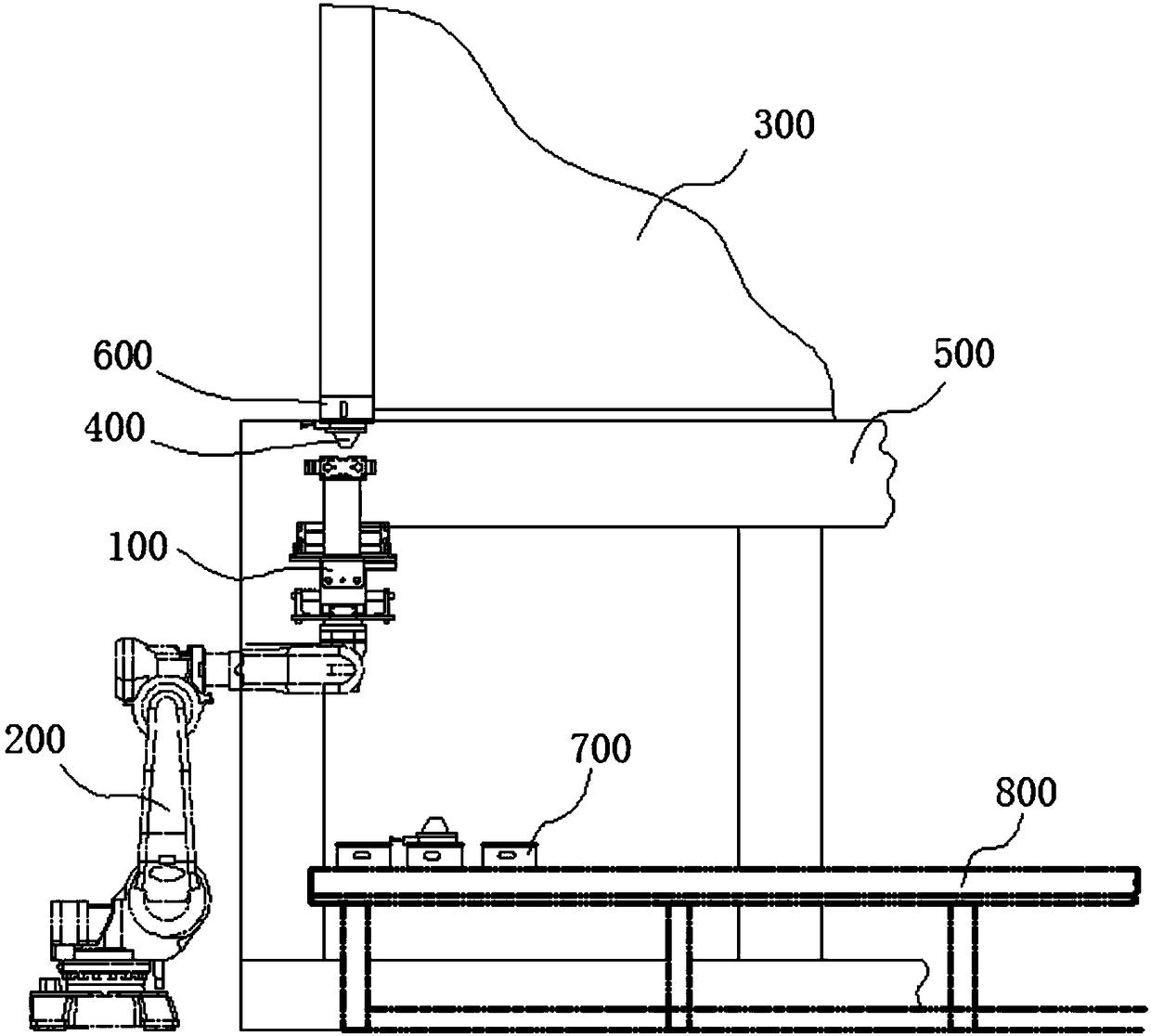

[0038] like figure 1 As shown, a container semi-automatic twist lock multifunctional disassembly device 100 disclosed by the present invention is installed on the mounting plate (not shown) of the industrial robot 200 during operation, and can be controlled by an automatic control system (not shown) , control the action of the disassembly device 100 of the semi-automatic twist lock and the industrial robot 200 to automatically unlock, disassemble or install and lock the semi-automatic twist lock 400 connected between the containers 300, which can completely replace the work of manual disassembly and assembly of the semi-automatic twist lock.

[0039]When the container 400 is placed on the bridge crane transfer platform 500 or on the bracket to be dismantled by the truck, the semi-auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com