Edge Error Control Method in Optical Processing of Small Grinding Head for Optical Lens

An optical lens and optical processing technology, which is applied in the field of optical parts processing, can solve the problems of increasing the cost of processing equipment and application range, difficulty in controlling the processing quality of edge parts, and warping, so as to reduce polishing costs, reduce convergence difficulty, and improve processing. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

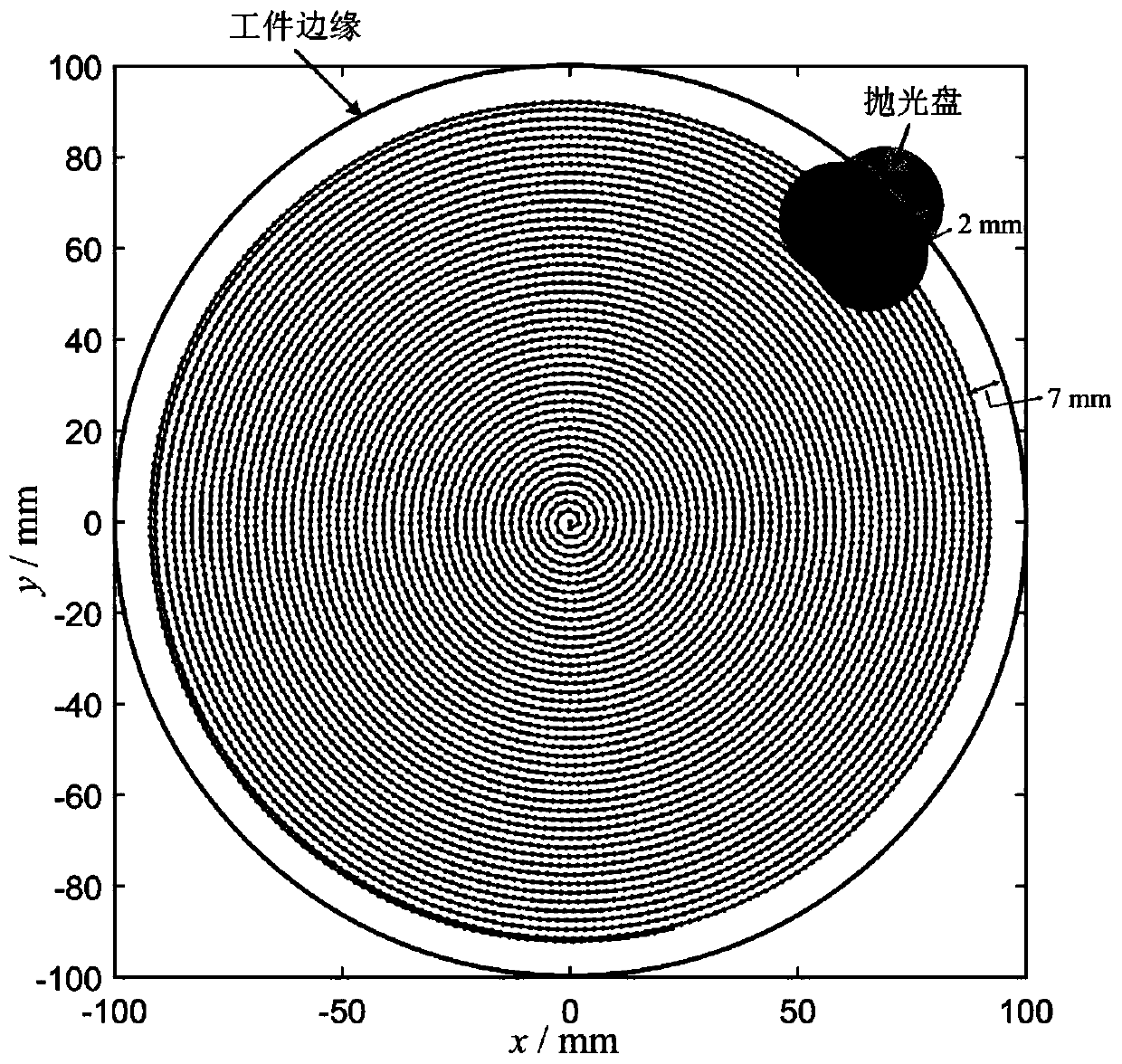

[0037] The polishing process of this embodiment is carried out on a polishing equipment based on industrial robots. The process parameters are set as follows: small grinding head diameter 25mm, applied pressure 10N, revolution speed 119rpm, rotation speed 200rpm, and the composition of the polishing liquid is CeO 2 , The concentration is 10% w.t, the ambient temperature is 23°C, the test workpiece to be polished is a concave BK7 optical glass with a diameter of 200mm, the radius of curvature is 1500mm, and the path is chosen as the Archimedes spiral.

[0038] Polish the workpiece by the following methods:

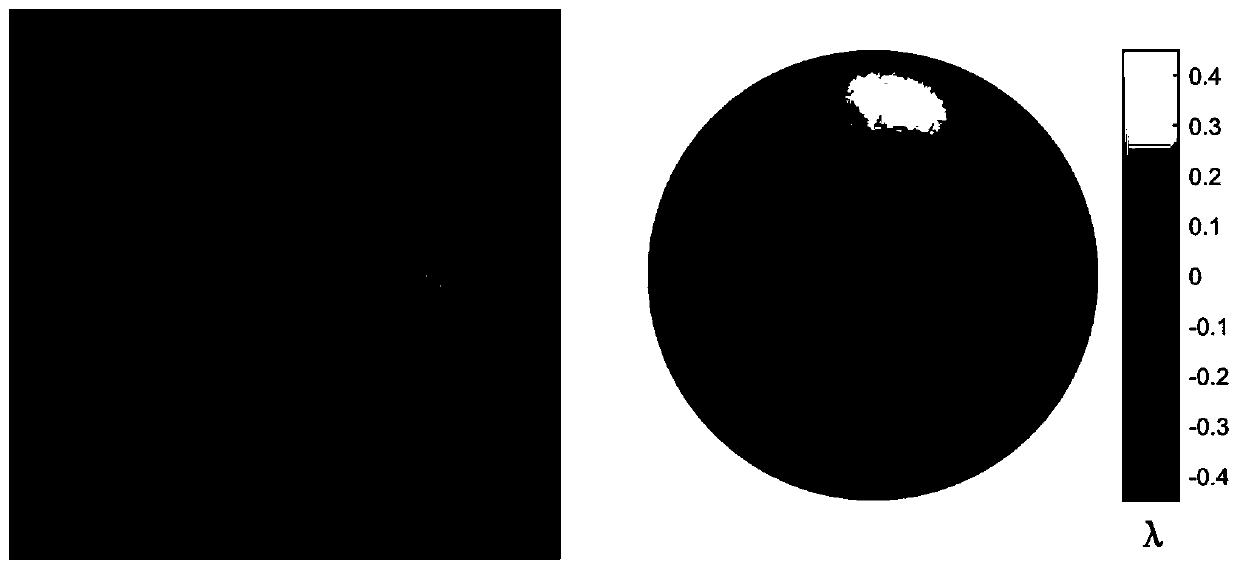

[0039] 1. Detecting surface error distribution: using laser interferometer to detect surface error of the workpiece to be polished, the results are as follows figure 1 Shown

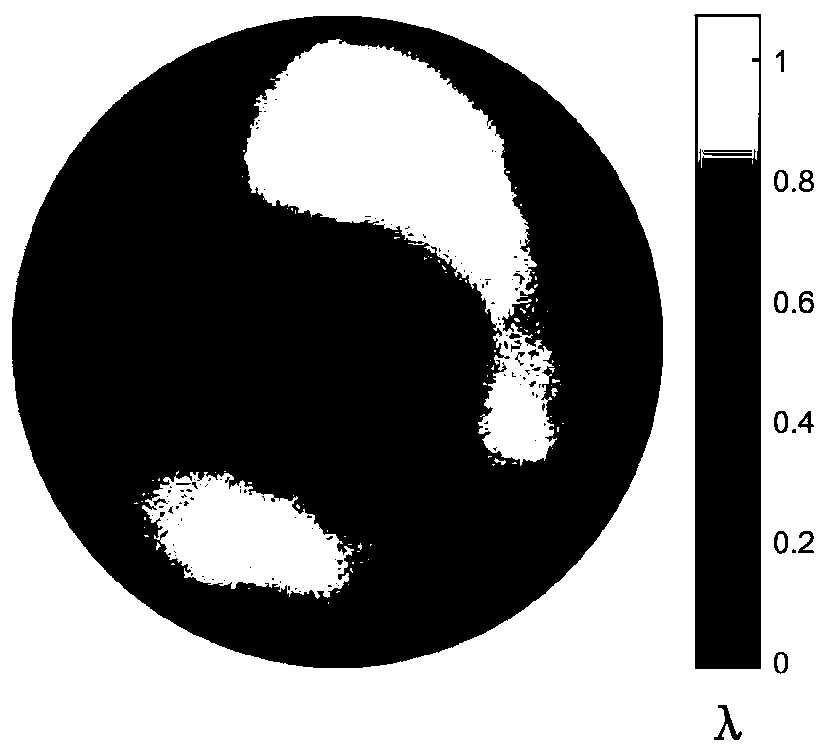

[0040] 2. Face shape adjustment: Use face shape adjustment technology to fine-tune the measured face shape. The parameter α in formula (1) is 0.7 and β is 2×10. -7 mm. Get adjusted back shape like figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com