Transferring point dust suppression device and method

A suppression device and transfer point technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of interfering with the airtight effect of the dry fog and dust suppression system, and achieve the effect of improving the dust removal effect, prolonging the contact time, and fully mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

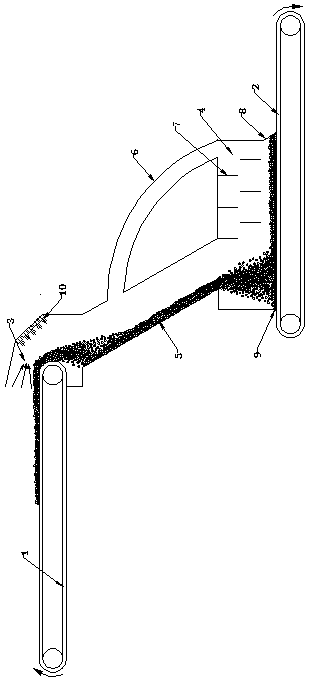

[0036] Taking a sinter return transfer point as the research object, the running speed of the upper and lower belts of the transfer point is 1.35m / s, the flow rate of transporting sinter is 3.88-14.78kg / s, and the material density is 3.856g / cm 3 , The maximum particle size of the material is 8mm, and the falling height is 0.9m. The particle size of the dust generated by the transported particles is in the range of 7.37-124.04μm. The present invention is described in detail below.

[0037] (1) Calculation method of induced airflow

[0038] The semi-empirical formula for the induced airflow obtained through experiments is:

[0039]

[0040] Where K is shown in the table below:

[0041]

[0042] The induced air flow calculated according to the formula is 0.0053~0.0685m 3 / s.

[0043] (2) Sealing device at transfer point

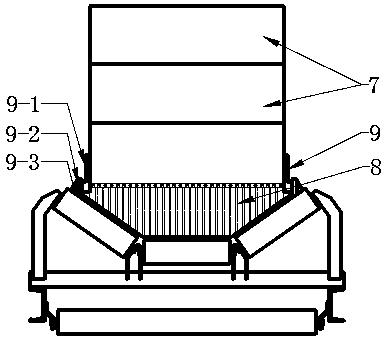

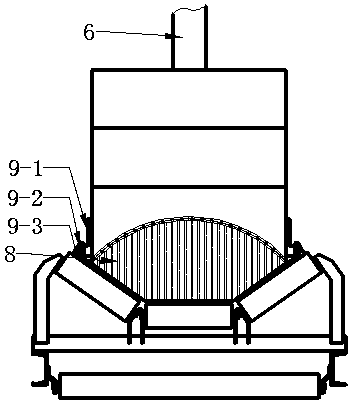

[0044] The actual size of the lower dust suppression cover 4 is 1.2m × 0.6m × 0.6m, the diameter of the drop pipe is 0.2m, and the inclination is 60°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com