Preparation method, application and cement additive of 2.5-dimethylpiperazine derivative

A technology of dimethylpiperazine and cement additives, applied in the field of cement additives, can solve problems such as long process and difficult process control, and achieve the effect of improving early strength, improving quality and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

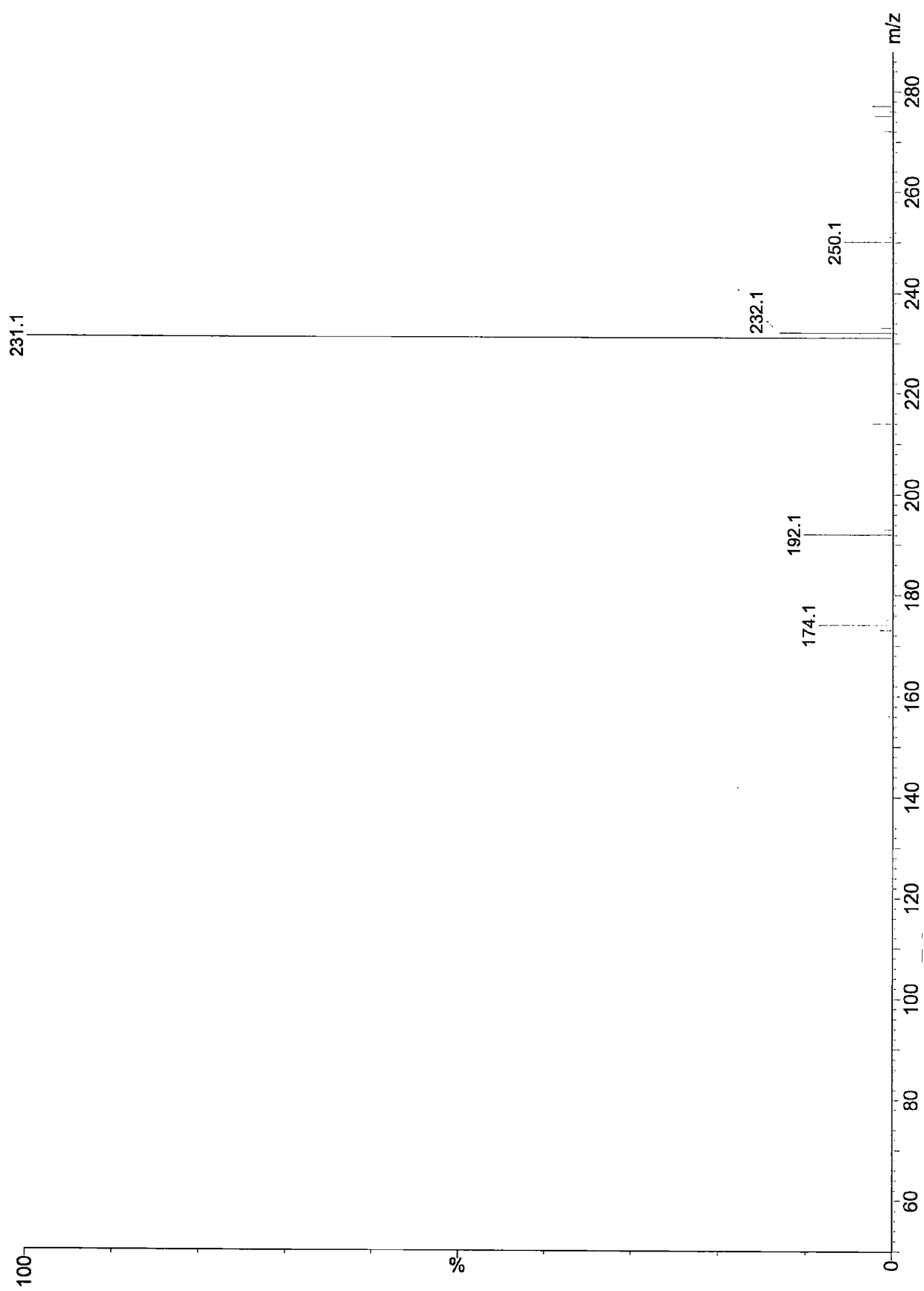

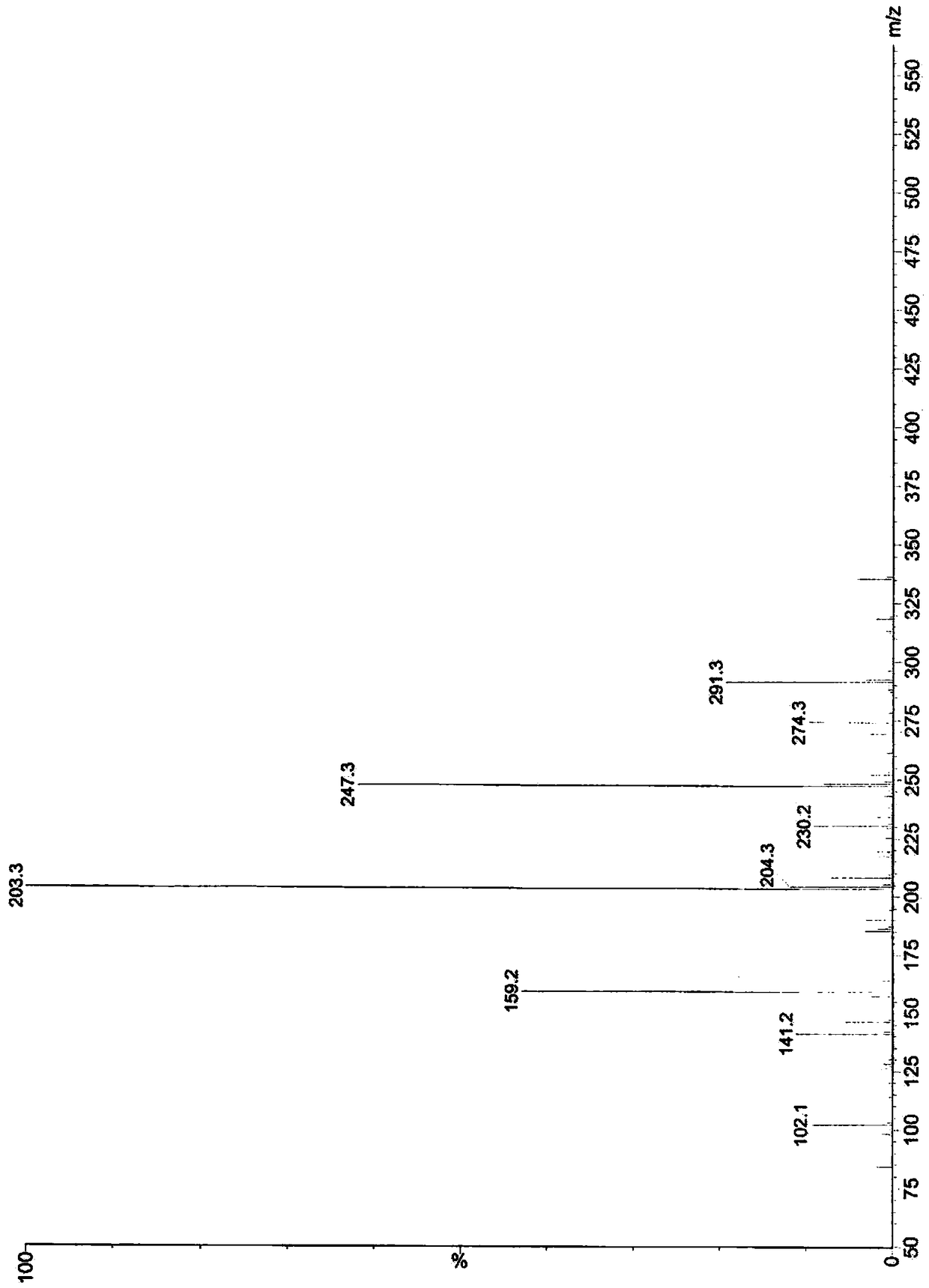

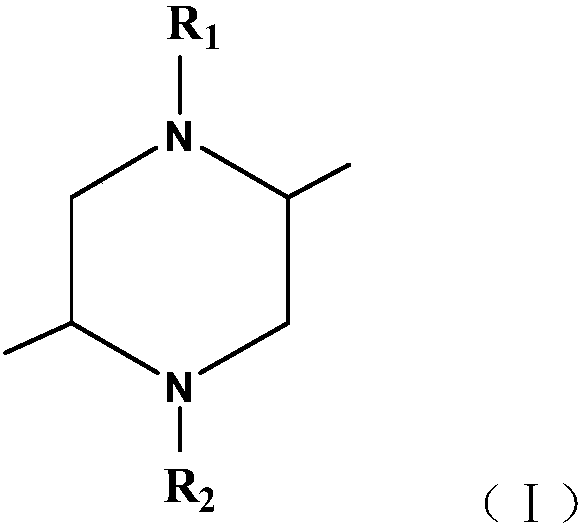

Method used

Image

Examples

Embodiment 1

[0044] The 2,5-dimethylpiperazine derivative is used alone as a cement additive, and when it is used alone as a cement additive, its addition method is the same as that of the existing cement additive.

[0045] 2,5-Dimethylpiperazine derivatives were tested as cement additives, and the test was carried out according to the GB / T 26748-2011 "Cement Grinding Aids" standard. The cement used was the benchmark cement with the following physical properties:

[0046]

[0047] In the cement module test, 2,5-dimethylpiperazine (HDMP), 1,4-bis(2-hydroxyethyl)-2,5-dimethylpiperazine (HEDMP), 1,4-bis (2-Hydroxypropyl)-2,5-dimethylpiperazine (HPDMP) refers to GB / T 17671-1999 "Cement Mortar Strength Test Method", GB / T 1346-2011 "Cement Standard Consistency Water Consumption Test" Method", to detect cement strength and standard consistency water demand, the specific test data are shown in Table 1.

[0048] Table 1 cement strength, standard consistency water demand data table

[0049] ...

Embodiment 2

[0055] The benchmark cement specification and test method in the present embodiment are the same as the benchmark cement specification and test method in Example 1.

[0056] Using 2,5-dimethylpiperazine (HDMP), 1,4-bis(2-hydroxyethyl)-2,5-dimethylpiperazine (HEDMP), 1,4-bis(2-hydroxypropyl Base)-2,5-dimethylpiperazine (HPDMP) is used as a cement additive alone, and the dosage is 0.04% of the cement mass. The specific test data are shown in Table 2.

[0057] Table 2 cement strength, standard consistency water demand data table

[0058]

[0059] "+" in Table 2 indicates that the compressive strength increases.

[0060] The data in Table 2 show that 2,5-dimethylpiperazine and its derivatives have the application characteristics of additives; compared with the blank cement sample, it is found that only 0.04% of the dosage is added to greatly improve the early and late strength of cement and reduce the Water requirement for standard consistency of cement. Among them, the maxi...

Embodiment 3

[0062] The benchmark cement specification and test method in the present embodiment are the same as the benchmark cement specification and test method in Example 1.

[0063] The material mix ratio of cement is: clinker 84%, gypsum 5%, limestone 4%, slag 2%, black slag 2%, iron slag 3%. Grinding fineness (0.08 / %) is 1.1, specific surface area (m 2 / kg) was 452, and the standard consistency (%) was 27.5.

[0064] Triethanolamine (TEA), 1,4-bis(2-hydroxyethyl)-2,5-dimethylpiperazine (HEDMP), 1,4-bis(2-hydroxypropyl)-2,5-bis Methylpiperazine (HPDMP) is used alone as a cement additive, and the dosage is 0.02% of the cement mass. See Table 3 for specific testing data.

[0065] Table 3 cement strength, standard consistency water demand data table

[0066]

[0067]

[0068] "+" in Table 3 indicates that the compressive strength increases.

[0069] The data in Table 3 shows that when the dosage is 0.02%, compared with the blank cement sample, it is found that the water deman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com