Super-concentrated laundry detergent and preparation method thereof

A laundry detergent and super-concentration technology, applied in chemical instruments and methods, detergent compositions, detergent compounding agents, etc., can solve the problems of high consumption, occupying space, unfavorable household storage, etc., and achieve good fluidity, use Convenience and the effect of solving the phenomenon of low temperature jelly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment the present invention is described in further detail:

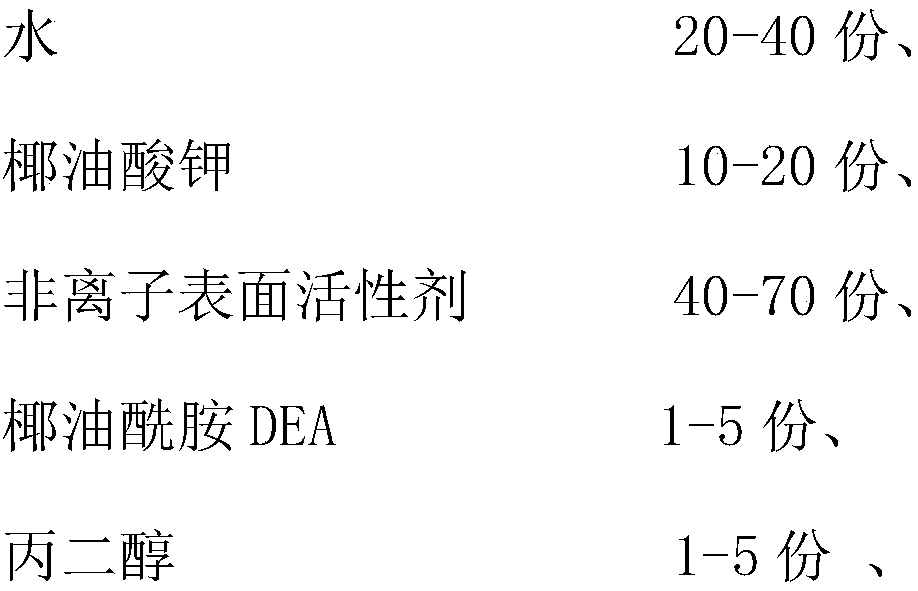

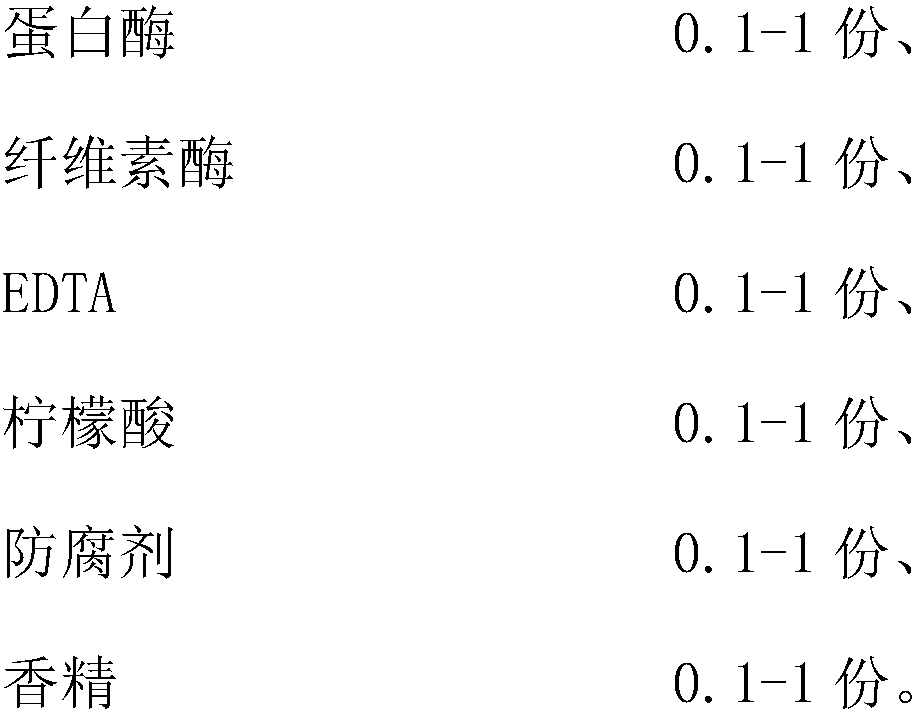

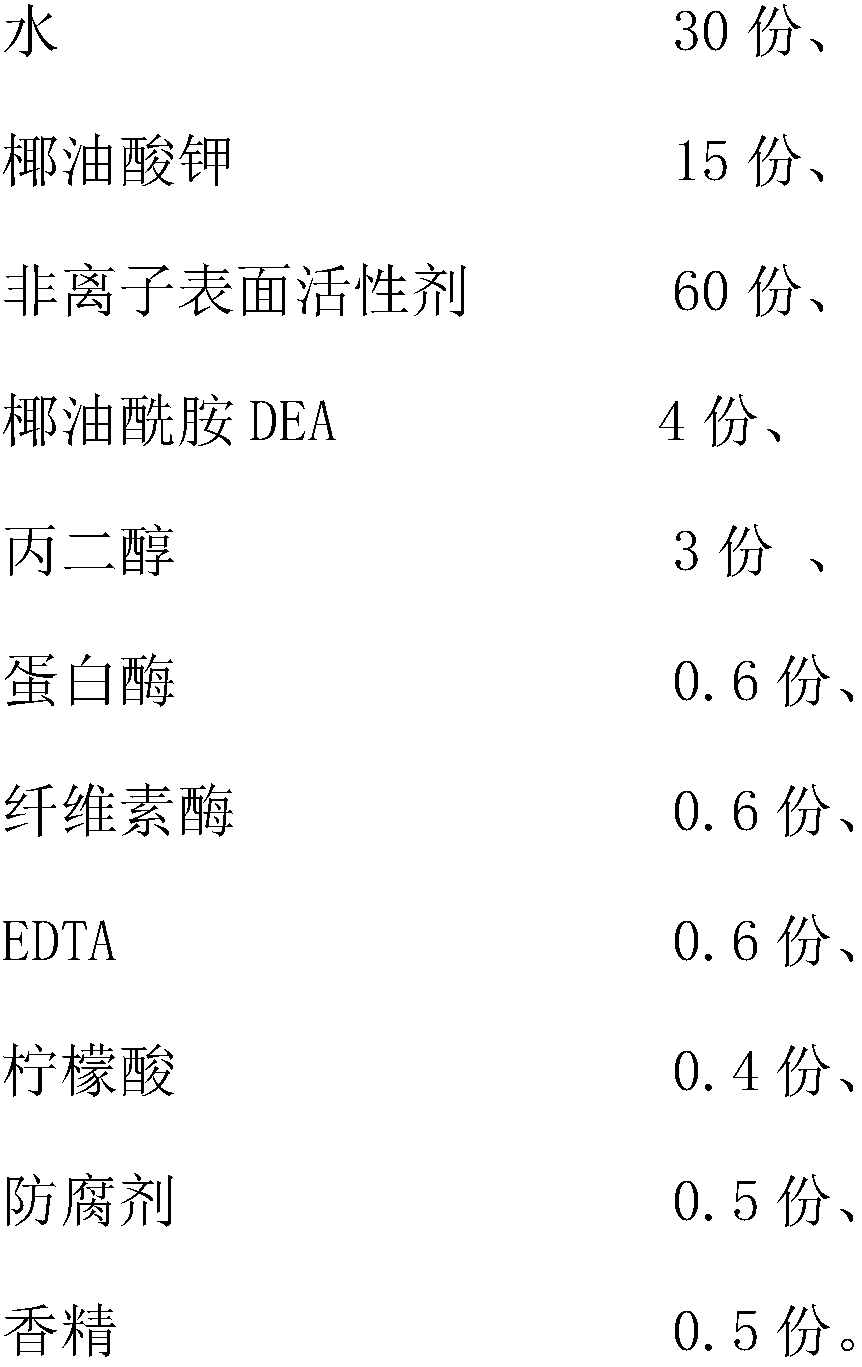

[0022] An ultra-concentrated laundry detergent, the raw materials and their proportions by weight are: 20-40 parts of water, 10-20 parts of potassium cocoate, 40-70 parts of isomeric fatty alcohol polyether, and 1 part of cocamide DEA -5 parts, propylene glycol 1-5 parts, protease 0.1-1 part, cellulase 0.1-1 part, EDTA 0.1-1 part, citric acid 0.1-1 part, preservative 0.1-1 part, essence 0.1-1 part. Preferably, 30 parts of water, 15 parts of potassium cocoate, 60 parts of isomeric fatty alcohol polyethers, 4 parts of cocamide DEA, 3 parts of propylene glycol, 0.6 parts of protease, 0.6 parts of cellulase, 0.6 parts of EDTA, 0.4 parts of citric acid parts, preservatives 0.5 parts, essence 0.5 parts. The preparation method of this super-concentrated laundry detergent is first to weigh each raw material according to the proportioning amount, then add the weighed raw material water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com