Clothes dewatering machine applicable to industrial production

A technology of clothes dehydration and dehydration machine, which is applied in the field of clothes dehydration, which can solve the problems of low efficiency, time-consuming, damage to the rotating shaft, etc., and achieve the effects of prolonging the service life, ensuring uniformity, and compact extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

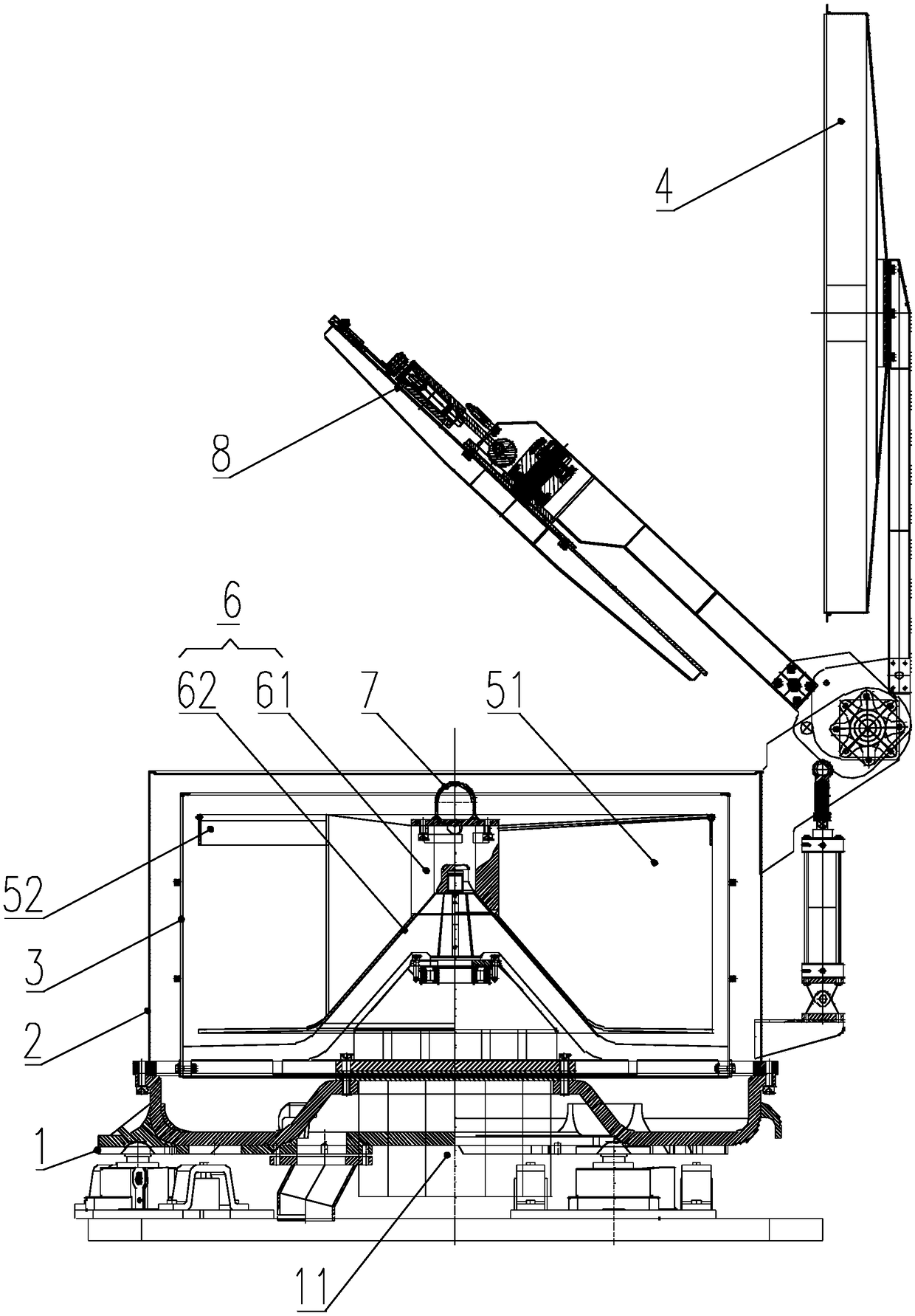

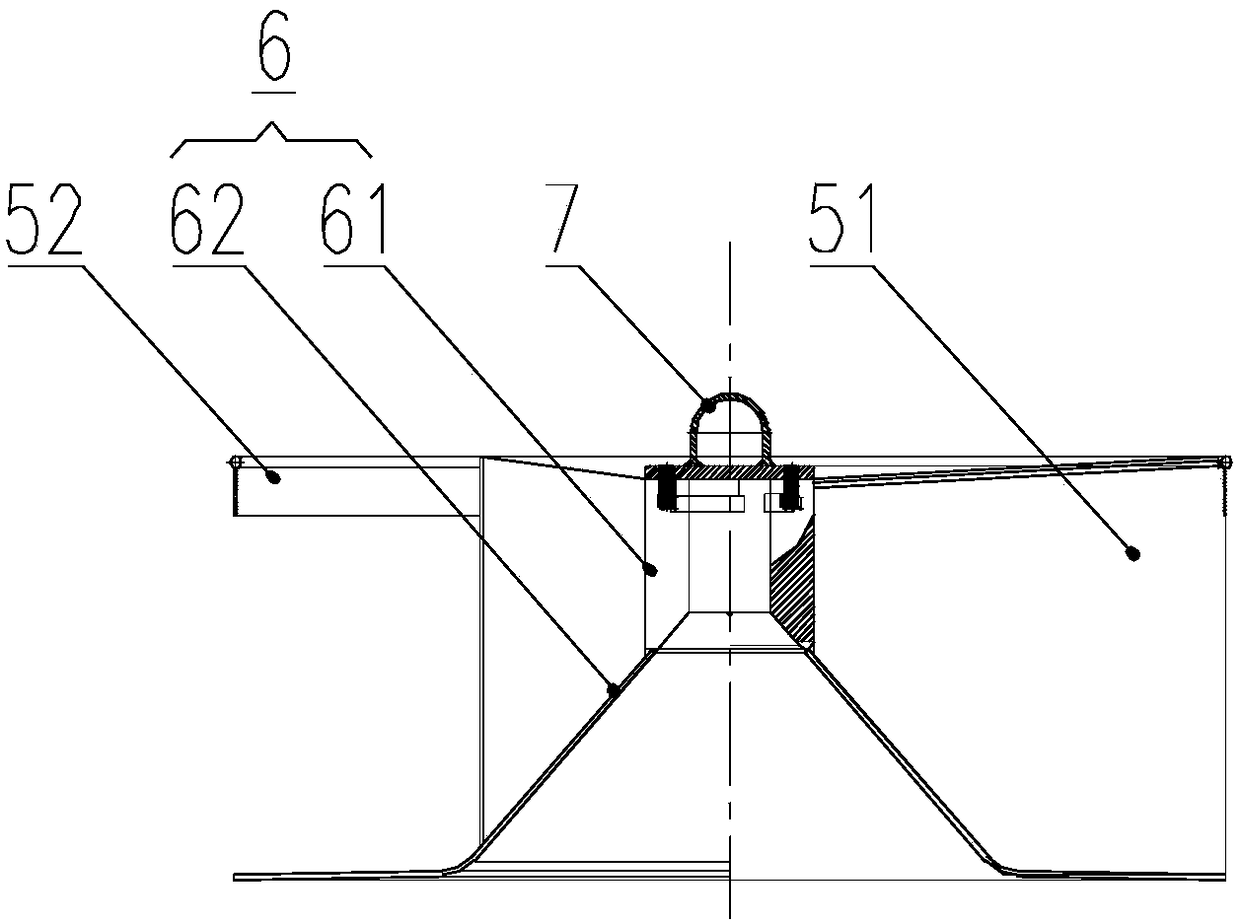

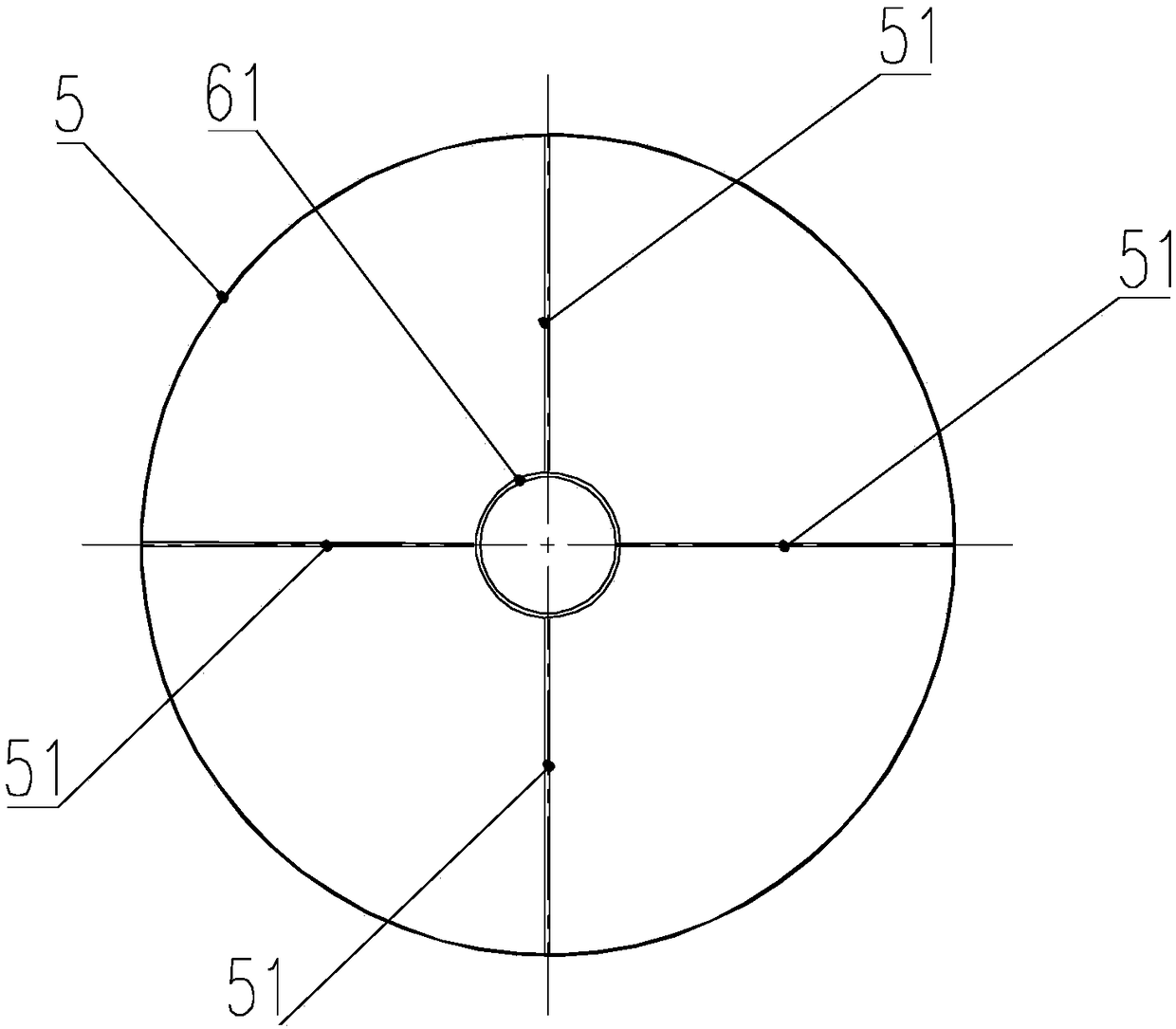

[0035] Such as figure 1 As shown, a clothes dehydrator suitable for industrial production includes a base 1, an outer barrel 2, a dehydration barrel 3, and an upper cover 4; the base 1 is provided with a rotating shaft 11 driven by a motor, and the outer barrel 2 is arranged on the base 1. Above, a number of small holes for drainage are evenly distributed on the barrel wall of the dehydration barrel 3. The dehydration barrel 3 is located in the outer barrel 2 and is driven by the rotating shaft 11 to make a circular motion. The outer barrel 2 and the top of the dehydration barrel 3 All are provided with a clothing input port, and the upper cover 4 is pressed against the outer barrel 2 by a hydraulic device; the dehydration machine is provided with a transfer barrel 5; the transfer barrel 5 is provided with a sleeve 6 and the upper part 61 of the sleeve is Cylindrical shape, the lower part 62 of the sleeve barrel is in the shape of a truncated cone; the top of the sleeve barrel 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com