Formation method for soft package lithium ion battery

A technology of lithium-ion batteries and chemical formation methods, which is applied in the field of soft-pack lithium-ion battery manufacturing, can solve the problems of poor consistency of SEI film formation, etc., and achieve the effects of improving the consistency of electrical properties and cycle life, improving penetration, and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

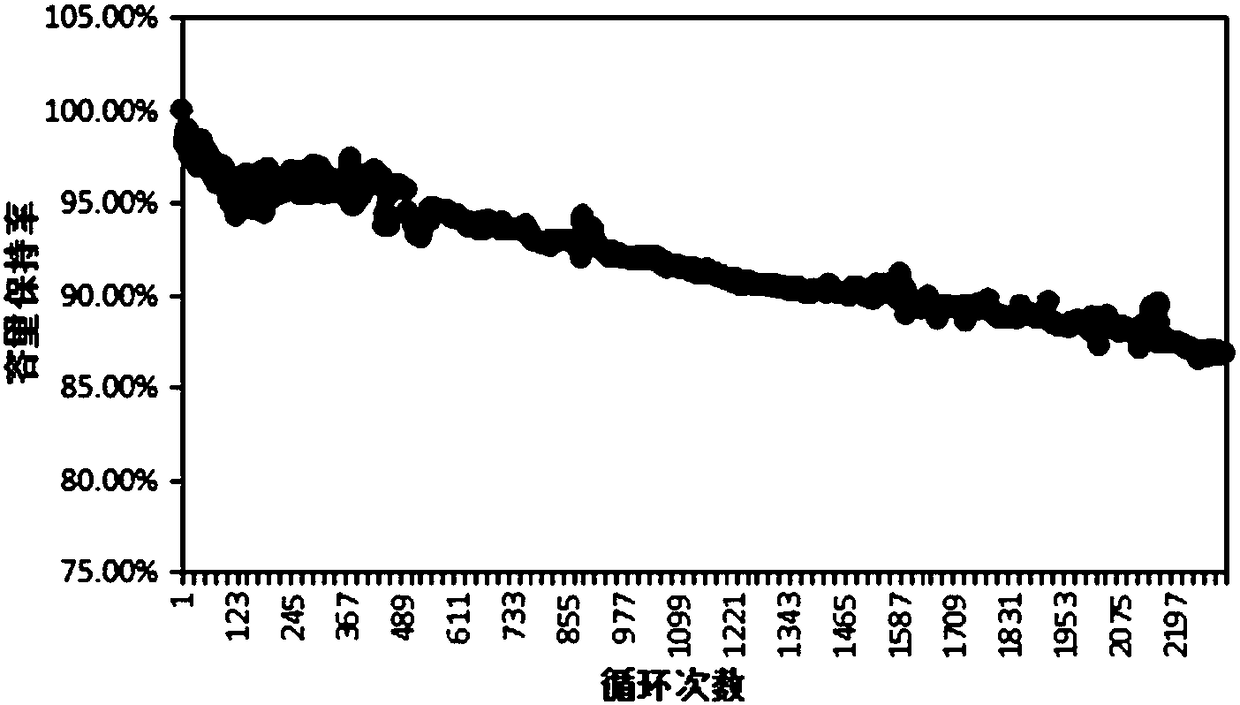

Embodiment 1

[0021] The formation method of the soft pack lithium-ion battery of the present embodiment adopts the following steps:

[0022] 1) Place the battery to be formed on a high-temperature pressurized formation equipment, keep the temperature of the battery cell at 40°C, and the surface pressure on both sides of the battery cell is 0.4Mpa, first use a constant current of 0.01C to charge to the first cut-off voltage 2.8V, then use 0.1C constant current to charge to the second cut-off voltage of 3.5V, and then use 0.5C constant current to charge to the initial cut-off voltage of 3.65V;

[0023] 2) Under the condition of room temperature and no surface pressure, use 0.1C constant current and constant voltage to charge until the set cut-off voltage is 4.0V, the cut-off current is 0.01C, and the formation is completed;

[0024] 3) Aging the battery after formation at 45°C for 36 hours.

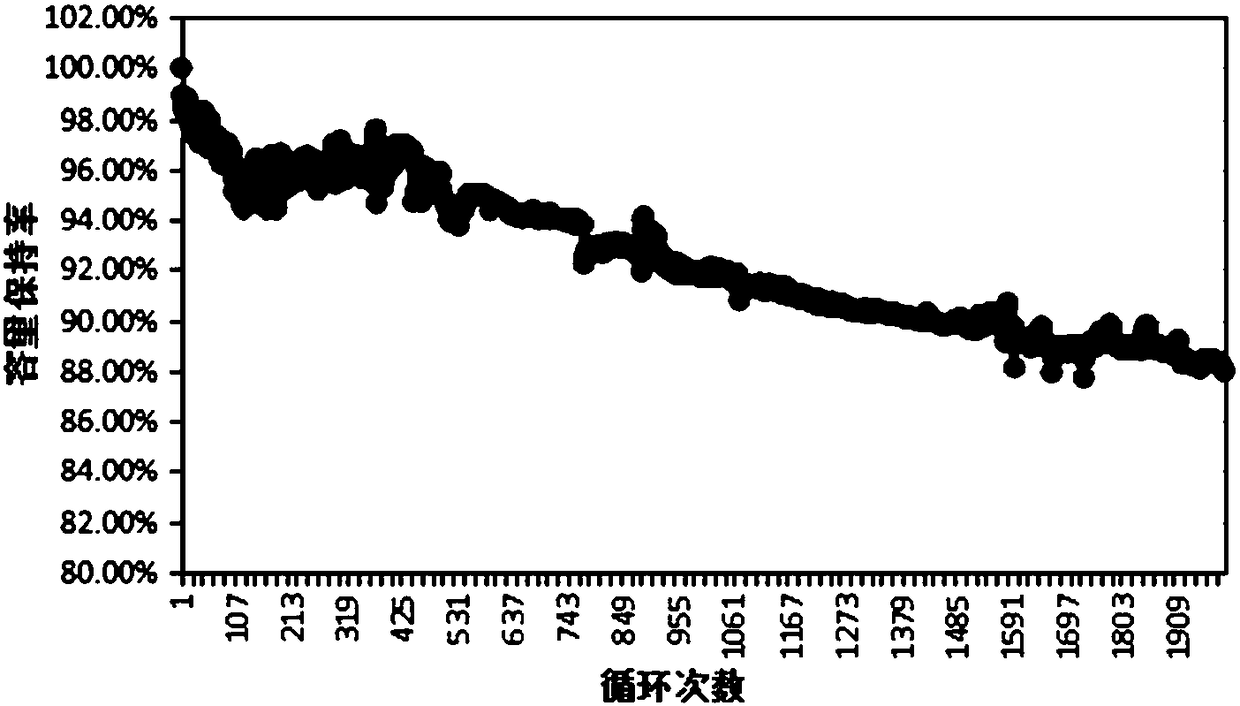

Embodiment 2

[0026] The formation method of the soft pack lithium-ion battery of the present embodiment adopts the following steps:

[0027] 1) Place the battery to be formed on a high-temperature pressurized formation equipment, keep the temperature of the battery cell at 60°C, and the surface pressure on both sides of the battery cell is 0.7Mpa, first charge it with a constant current of 0.05C to the first cut-off voltage 2.8V, then use 0.3C constant current to charge to the second cut-off voltage of 3.5V, and then use 1.0C constant current to charge to the initial cut-off voltage of 3.65V;

[0028] 2) Under the condition of room temperature and no surface pressure, use 0.2C constant current and constant voltage to charge until the set cut-off voltage is 4.0V, the cut-off current is 0.02C, and the formation is completed;

[0029] 3) Aging the battery after formation at 50° C. for 24 hours.

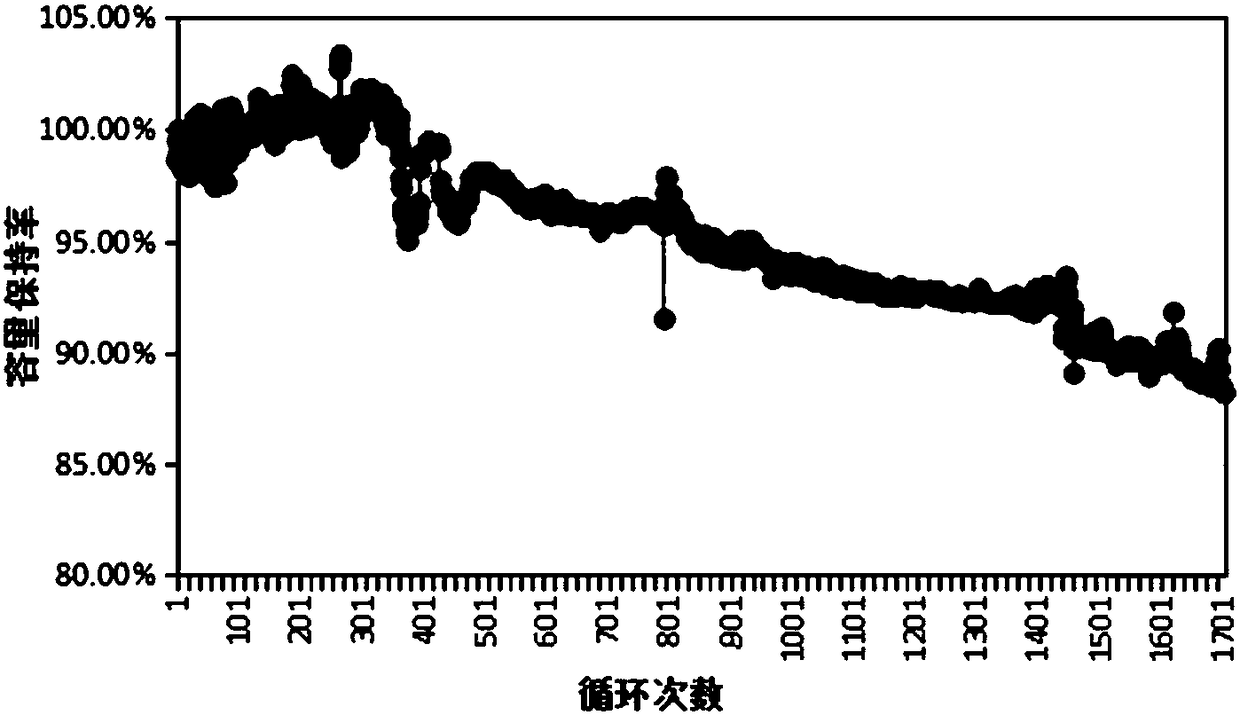

Embodiment 3

[0031] The formation method of the soft pack lithium-ion battery of the present embodiment adopts the following steps:

[0032] 1) Place the battery to be formed on the high-temperature pressurized formation equipment, keep the temperature of the battery cell at 70°C, and the surface pressure on both sides of the battery cell is 1.0Mpa, and charge it with a constant current of 0.1C to the first cut-off voltage 2.8V, then use 0.5C constant current to charge to the second cut-off voltage of 3.5V, and then use 2.0C constant current to charge to the initial cut-off voltage of 3.65V;

[0033] 2) Under the conditions of room temperature and no surface pressure, charge with a constant current and constant voltage of 0.5C until the set cut-off voltage is 4.0V, the cut-off current is 0.05C, and the formation is completed;

[0034] 3) Aging the battery after formation at 60° C. for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com