A cement matrix for concrete canvas systems

A concrete canvas and cement technology, applied in the field of concrete canvas materials, can solve the problems of high energy consumption, high pollution, alkali-induced cementing material powder loss, etc., and achieve the effect of improving drying shrinkage and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the novel cement matrix that is used for concrete canvas system provided by the present invention, according to parts by weight, this cement matrix is made up of following components: industrial waste residue: 550 parts-650 parts, water glass: 280 parts-380 parts, Gelling agent: 85-125 parts, shrinkage reducing agent: 80-120 parts. Among them, the industrial waste slag is granulated blast furnace slag; the water glass is instant water glass powder, and the water glass modulus is 2.0; the gelling agent is sulfoaluminate cement, Belite sulfoaluminate cement, high alumina cement or silicic acid Salt cement; shrinkage reducing agent is calcium oxide, magnesium oxide.

[0025] The method of using the above-mentioned new cement matrix for the concrete canvas system is to fully stir the cement powder, fill it into the three-dimensional fabric, and then sprinkle it with water; in order to make the alkali-activated slag suitable for the concrete canvas system as ...

Embodiment 2

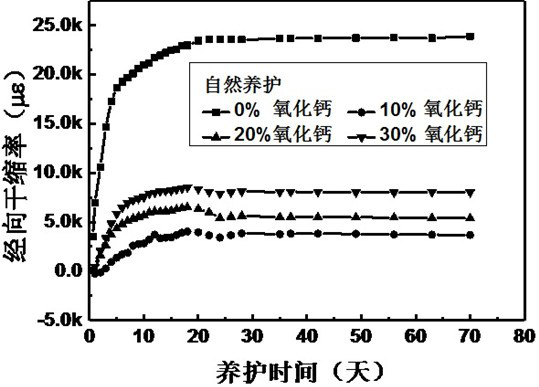

[0027] Example 2: The drying shrinkage performance of the new cement matrix has been significantly improved after the shrinkage reducing agent is added, and it has been further optimized when the water immersion curing condition is adopted. For details, see image 3 Figure 4 and Figure 5 .

Embodiment 3

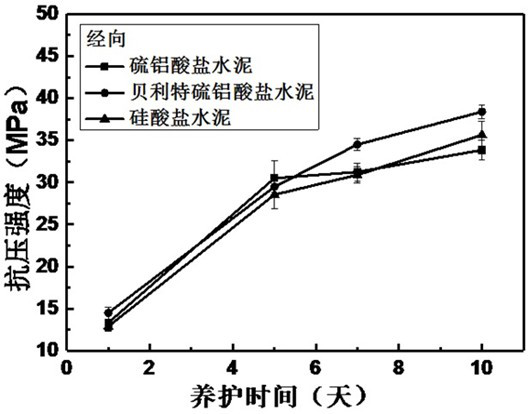

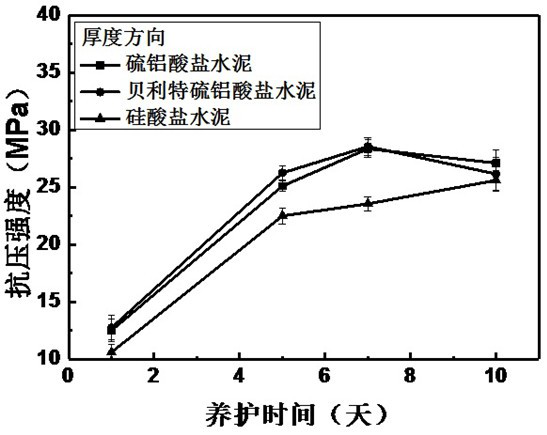

[0028] Embodiment 3: the cement matrix provided by the present invention prepares the concrete canvas sample, weighs 310 parts of water glass, 630 parts of slag and 94 parts of gelling agent powder and mixes evenly, stirs 3min, is prepared into uniform cement powder, fills to use In the 10mm polyester three-dimensional spacer fabric for the preparation of concrete canvas, it is sprayed with water after molding, and the water-binder ratio is 0.37.

[0029] The samples were cured naturally at a temperature of 20±2°C and a humidity of 60±5%. Then, cut a sample of 10mm (length)*10mm (width)*10mm (thickness), and measure its compressive strength. The compressive strength of the sample was tested with reference to the standard ASTM C109 / C109M, and the setting time was tested with reference to GB / T1346-2001 "Cement Standard Consistency Water Concentration Test Method for Setting Time Stability".

[0030] Test results: The final setting time of the concrete canvas sample is 85 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com